Researchers at Toyohashi Tech and Duke University have found a way to produce new copper alloy nanoparticles, which can be used as the main component of affordable conductive inks with high oxidation in Printed Electronics,including those for packaging.

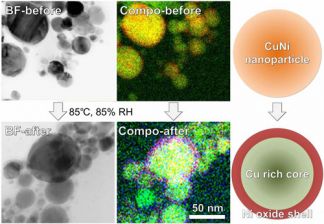

Currently the low performance and high cost of conductive inks limit the uptake of printed electronics. These researchers electrically exploded alloy or twisted metal wires in water with a mild reducing agent (Vitamin C) in order to produce the nanoparticles. The reduction in conductivity was subsequently measured under harsh conditions (high temperature and high humidity).

"We have been working on developing a 'wire explosion' method to produce novel metal nanoparticles. Then, we found that some of the produced copper alloy nanoparticles possessed both high oxidation resistance and low electrical resistance," explains Assistant Professor Go Kawamura. "Additionally, the nanoparticles have the advantage of being inexpensive because the production process is very economical and environmentally friendly."

With further improvement of the electrical conductivity and oxidation resistance, copper alloy nanoparticles prepared by wire explosion could be used for the production of high-performance affordable conductive inks, which will contribute to the advancement of printed electronics, they believe.