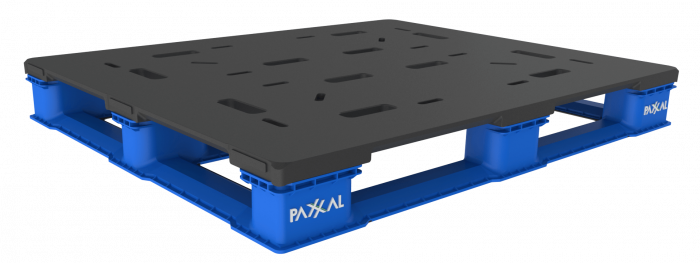

Having spent north of $50 million to date refining its plastic pallet offering, Ben Stoller, Paxxal’s CEO, states that his company’s long-lasting 48×40” plastic pallet stands out as one of the “true” GMA pallets on the market. It meets the guidance of racking 2,800 pounds in either direction while being under 50 pounds in weight. Paxxal is able to hold the line on weight as well as price thanks to the use of its proprietary internal filler material (which is fully recyclable), bridging of technologies, and superior engineering.

The Paxxal manufacturing process involves a bridging of technologies – a fully automated rotomolding system as well as injection molding. According to Stoller, the company continues to make process improvements that are helping it to reduce cycle time and boost throughput. Paxxal has lodged more than 28 patents on its’ plastic pallet in the process.

Targeting applications in the FMCG sector, the Paxxal pallet has a stated life expectancy of 70 to 100 trips. It is also UL fire rated and FDA food grade. Further, the plastic pallet is hermetically sealed and fully repairable for most damage experienced in the supply chain.

Additionally, the company has made investments in information technology, including its PaxTrax IoT tracking system and its PaxxChain blockchain offering. Stoller, who also serves as Reusable Packaging Association chairman, states that PaxxChain’s vision is to enable established businesses to create value and solve real-world economic problems through lowering the barrier to blockchain technology utilization. Stoller says, “Our vision is to create an entirely new store of value for data via PaxxCoin by identifying opportunistic cost savings from seemingly uncorrelated data never before seen.”

“Experts and consultants continue to hype the use of artificial intelligence,” he said, but in order to get to AI, you need to have access to real-world data. Our technologies allow our customers to do exactly that.”

“This is the most disruptive plastic pallet technology in the last 20 years,” he concluded.

In 2022, Stoller will also be serving the second year of his term as Reusable Packaging Association (RPA) Chairman of the Board through 2022. “It’s been a remarkable year for our industry and association, and much remains on our agenda to support an exciting outlook for growth,” he said in a release. “I look forward to continuing my work with RPA’s talented leadership team to expand a stronger, more competitive market for reusable packaging systems.”