The solution that could help with the plastic pollution problem: is an enzyme that can chemically break down many bottles and packaging, sometimes within 24 hours.

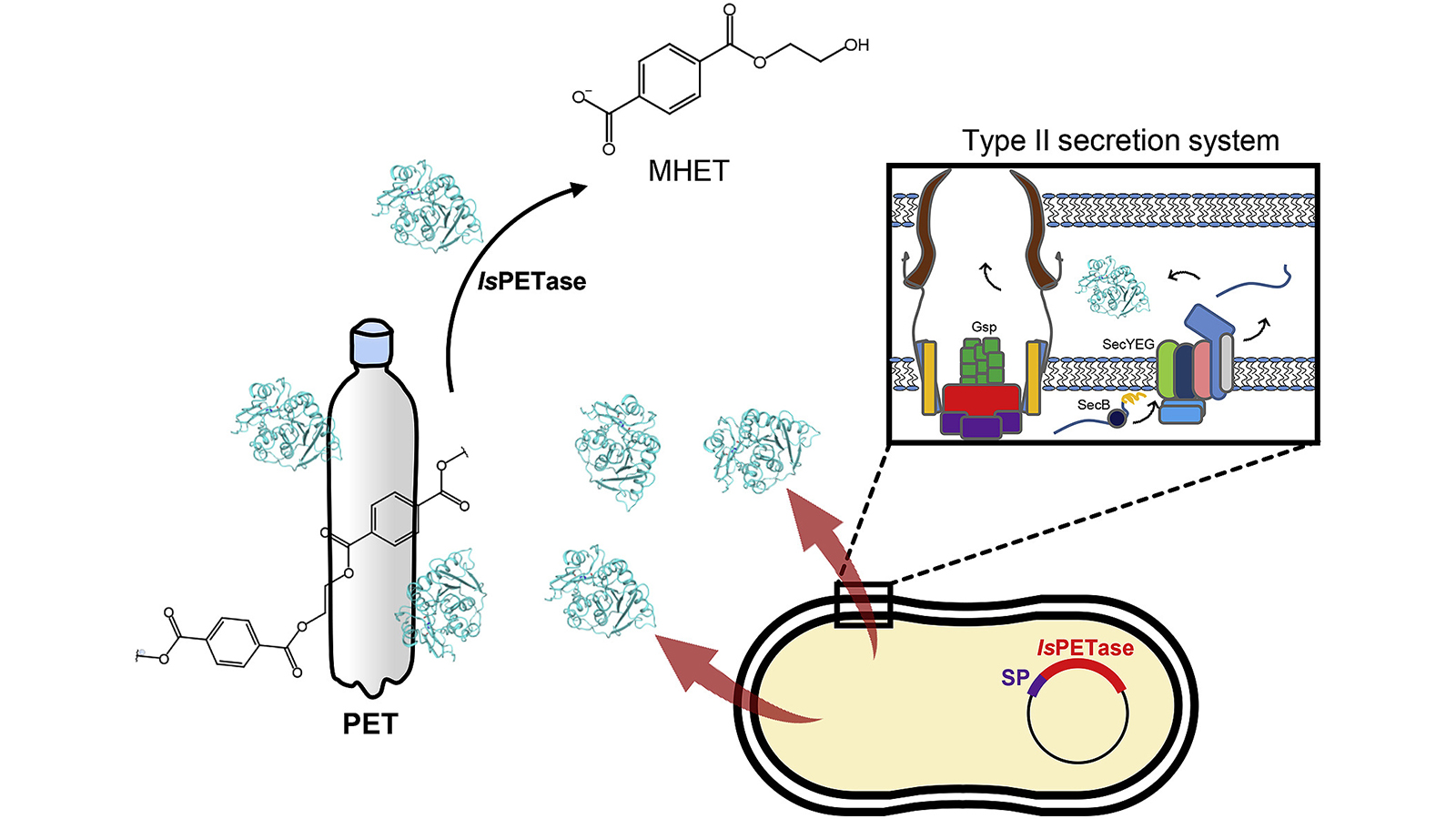

Researchers at the University of Texas describe the development of a "plastic-eating enzyme" in the April 27 edition of the peer-reviewed journal Nature. They used machine learning technology to mutate the natural enzyme PETase into one that could quickly break down plastics made with the polymer polyethylene terephthalate, also called PET.

The enzyme uses a “circular process” to break down the plastic into smaller parts and then chemically transforms it into a smaller, reusable plastic, researchers said in a university news release describing the findings. The process can sometimes be as fast as 24 hours – and is a much more environmentally friendly option than putting the plastics into a landfill or burning them.

“The possibilities are endless across industries to leverage this leading-edge recycling process,” one of the study's co-authors Hal Alper, a chemical engineering professor at the University of Texas, said in the release.

“Beyond the obvious waste management industry, this also provides corporations from every sector the opportunity to take a lead in recycling their products," he said. "Through these more sustainable enzyme approaches, we can begin to envision a true circular plastics economy.”

The enzyme won't work on every kind of plastic, but it can break down PET, which is found in consumer packaging making up about 12% of all global waste, the researchers say.

Among the plastic products made with PET:

- Cookie containers

- Soda and water bottles

- Fruit salad packaging

- Some polyester fibers and fabrics

-

The researchers are currently working on industrial use methods for the plastic-eating enzyme, which can break down plastics when used at temperatures less than 122 degrees. They foresee potential for cleaning up landfills and polluted sites, too.

“When considering environmental cleanup applications, you need an enzyme that can work in the environment at ambient temperature," Alper said. "This requirement is where our tech has a huge advantage in the future."

-

The work was funded by ExxonMobil as part of its ongoing research agreement with the university.

California Attorney General Rob Bonta last week subpoenaed ExxonMobil as part of an investigation into what he called the petroleum industry's “historic and ongoing efforts to deceive the public" while causing a global plastic pollution crisis.

The company called the allegations meritless and said it is the first to have “commercial-scale advanced recycling technology” at a major facility to convert used plastic into the material that can be used to make new plastic.