In a move to address the pressing issue of plastic waste and carbon emissions within the booming cannabis industry, Spark Sourcing is excited to introduce eco-shell™, a game-changing solution that can reduce plastic by up to 50% and carbon emissions by up to 70%, all while offering 100% recyclable packaging. The appointment of Terry Faulkner, a dedicated cannabis packaging expert based near Boulder, Colorado, underscores Spark Sourcing's commitment to revolutionizing the industry's packaging practices.

The cannabis industry has experienced exponential growth in recent years. However, this growth has been accompanied by a surge in plastic waste, which poses a serious environmental concern. Terry Faulkner recognized that eco-shell™ could be the ideal solution for the cannabis sector. Despite being utilized in numerous industries and applications (pharmaceutical packaging, industrial packaging, cosmetics, household products, toys, yoga mats, etc), eco-shell™ has not yet been adopted for cannabis packaging, making it a much-welcomed innovation.

Perhaps more than any other industry, cannabis packaging should lead the way in alternative or sustainable packaging. If sustainability is part of the cannabis counter-culture, why aren't more firms taking action? Are cannabis companies actually meeting their sustainability goals? Maybe, maybe not. One way to meet them is through plastic reduction.

There are current plastic and carbon reduction options for cannabis brands and packaging manufacturers, but none are ideal. In theory, there are a lot of exciting things about bioplastics in cannabis packaging. The reality, however, is different. Bioplastics cannot be recycled and must be sorted out from recyclable plastics by consumers, which is not easy and is time-consuming. The consumer should then place them in a specific environment where these plastics can compost, but few consumers have these facilities. As a result, the vast majority of bioplastics just get tossed and end up in a landfill where composting conditions are not met, and the plastic will not biodegrade. With the amount of energy needed to create the bioplastics and the unfortunate end of life, there is no carbon reduction and an increase in plastic waste.

Other products claim degradability through using additives to virgin plastic that will allow it to biodegrade. They may have the proper certification, but that can be obtained for as little as 5-10% degradation in 90 days. If this slow-degrading material (that cannot be recycled) goes to a composting facility with fast-degrading material, it will gum up the works. So, if it is not composted following the proper steps by consumers, it will end up in the landfill (where compost conditions are not met) or incinerated, releasing more carbon.

Another problematic solution is when products use fibers (like hemp) to reduce plastic in their compounds and claim eco-friendliness. However, the product is not recyclable once you add that hemp (at most just 10%). It also cannot biodegrade, so it either gets incinerated or winds up in a landfill.

Aside from these less-than-ideal end-of-life for these solutions, another truth in the cannabis packaging industry is that end consumers overwhelmingly support sustainable packaging and will choose to buy it over non-sustainable options. However, they are also not willing to pay more for it. This poses a problem for brands and manufacturers as the sustainable solutions mentioned above are all quite expensive.

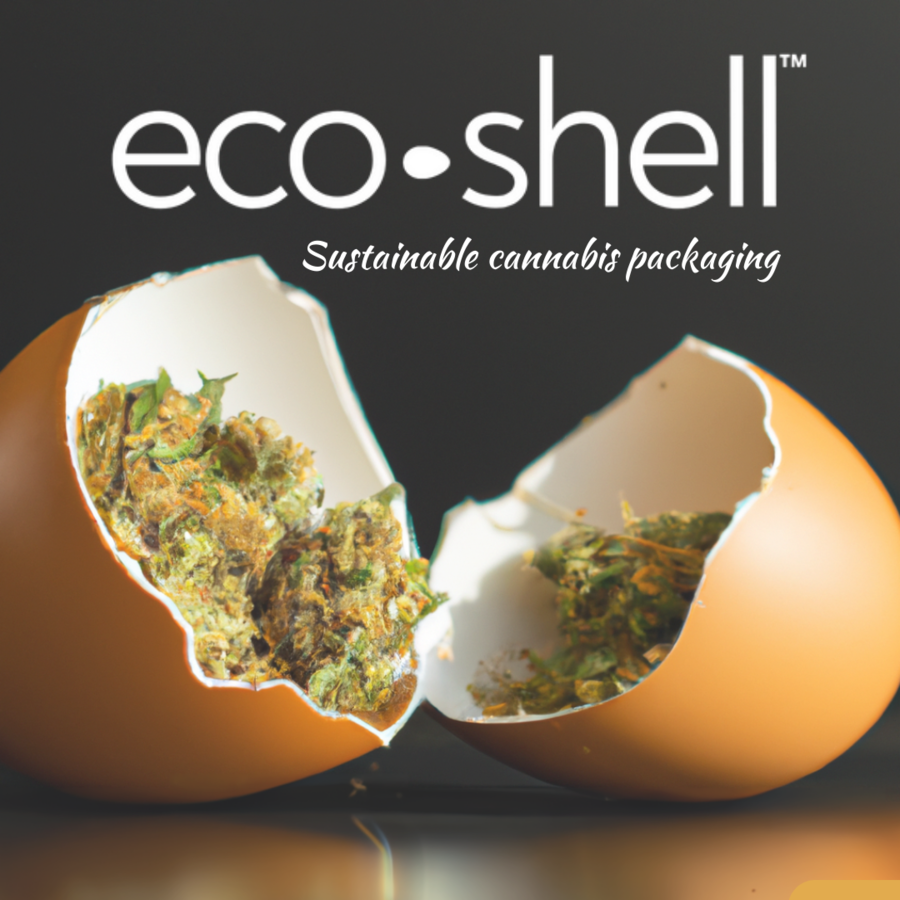

Enter eco-shell™ – a bio-calcium compound derived from eggshells through a patented process (US, UK, Taiwan, Australia, and China patents). Boasting a remarkable 70% lower carbon emission compared to virgin plastics, eco-shell™ has garnered SGS certification as an effective waste, carbon, and plastic reducer, in addition to earning the EN 13430 certification for recyclability, giving it a much more ideal end-of-life than the options mentioned previously. Furthermore, eco-shell™ proudly holds EU RoHS, REACH, antibacterial, and high FIR emissivity certifications, solidifying its eco-friendly credentials.

Another marvel of eco-shell™ lies in its effortless integration into existing manufacturing processes. Distributed as pellets, eco-shell™ can be seamlessly incorporated into compounds for an instant and substantial reduction in plastic and carbon. Moreover, it synergizes seamlessly with recycled and ocean-bound plastics, enhancing overall carbon reduction. Unlike other solutions that require costly material testing, machinery upgrades, and packaging redesigns, eco-shell™ offers a swift transformation. This makes for an easy way for companies to meet upcoming plastic and carbon reduction mandates.

Regarding pricing, eco-shell™ pellets are similar in cost to virgin polypropylene, mitigating the sticker shock often associated with alternative bioplastics and sustainable solutions. Eco-shell™ epitomizes the three R's: Reduce, Reuse, and Recycle. It also allows the cannabis industry to maintain the pricing and other advantages of plastic while taking a serious step toward a more circular plastic economy for cannabis.

Terry Faulkner envisions the potential of eco-shell™ in a range of cannabis packaging products, including pop-tops, tubes, jars, bottles, lids, caps, closures, and even mouthpieces and casings for vapes. Regarding the latter, the higher melting point of plastic made with eco-shell™ makes it an ideal solution, while its antibacterial version is perfect for mouthpieces.