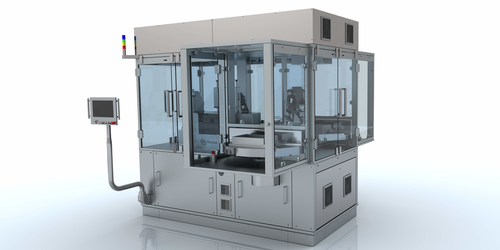

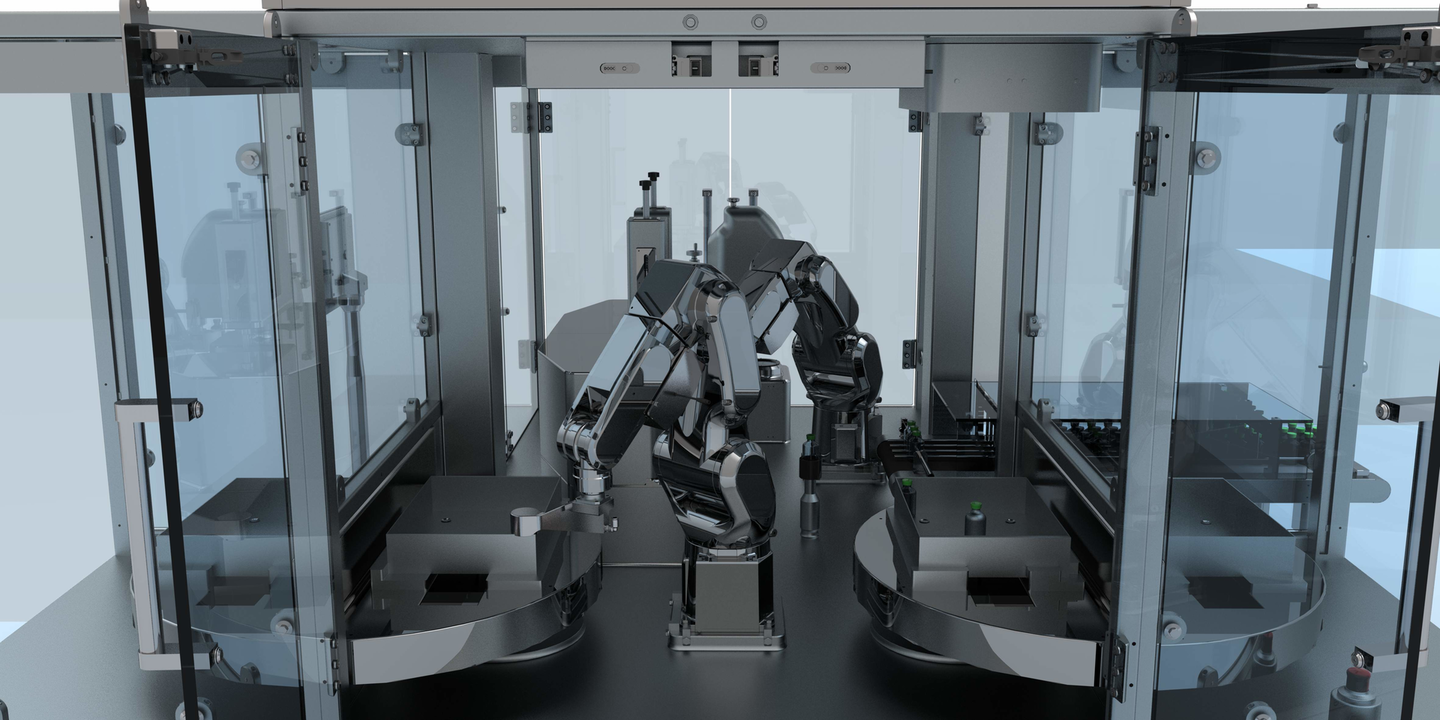

Italy-based Stevanato Group, a producer of glass primary packaging and provider of integrated capabilities for drug delivery systems, is launching a modular, robotic inspection system that incorporates artificial intelligence with accrued machine learning capabilities at its Interphex Virtual Exhibition (July 15-17). The company’s Vision Robot Unit (VRU) is a reliable, autonomous module capable of automatically inspecting both cosmetic and particle properties without human intervention. The VRU’s island design, for which there is a patent pending, comprises a highly versatile “plug & play” concept with a freely configurable infeed and outfeed. It is also scalable, as multiple vision inspection units can be added to increase throughput. Its no glass-to-glass inspection process significantly mitigates the likelihood of product damage or breakage. Thanks to its AI technology, VRU is able to improve its inspection performance. The unit can quickly react to changing product characteristics – including active ingredient variations, differing fill levels and different containers–even throughout a single batch. It is also adaptive, exhibiting continuous learning from both production and operator stimuli. The result is an improvement in the reduction in both false rejects and, even more importantly, false positives. The VRU is suited to a broad array of applications in the pharma development and manufacturing landscape, including biotech products such as monoclonal antibodies (mAbs), vaccines and lyophilized drugs. Suitable for inspecting high-value products, the machine can be employed both in laboratory settings and for small batch production. The Vision Robot Unit is designed to meet emerging “smart factory” needs for a fully automated, flexible inspection system that enhances control process reliability. The unit includes automatic format changes, and the ability to gradually reduce set up times via image and data collection. The VRU is available with or without additional collaborative robots. Basic models offer particle inspection, while an optional add-on provides cosmetic inspection. Recent advancements in artificial intelligence promise to optimize pharma visual inspection processes, providing advanced analytical tools to identify and classify defective products with greater accuracy and robustness.