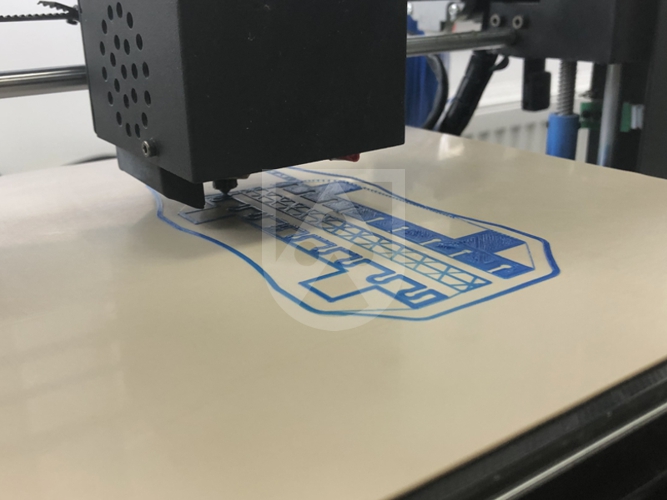

With the new 3D printer build surface made of SUSTAPEEK, Röchling wants to simplify work processes for 3D printers in fused deposition modelling. The application of the first filament layer on the build surface plays a key role in achieving optimum printing results. The 3D printer build surface must have a high adhesive effect so that the printing object has high stability during the printing process and remains fixed in the specified position. Conventional build surfaces usually have to be processed for a strong adhesive effect. The surface is, for example, coated with foils or treated with liquid adhesive. This costs time and money. Specially applied adhesives are difficult to remove from the object and from the surface. At the same time, due to the high temperatures during printing, films can lose their adhesion properties over time and must be replaced. Strong adhesion During material application in the printing process, a 3D printer build surface made of high-performance plastic SUSTAPEEK adhere strongly to the printing object without any surface treatment. This saves time and money. “We want to optimise and simplify the work process for printers”, says Stefan Maurer, Head of Sales & Marketing at Röchling Sustaplast in Lahnstein, Germany. “Our SUSTAPEEK 3D printer build surface can be used simply, without surface treatment.” If the adhesion is insufficient, it can be further increased via additional roughening. Prototypes, model making, mechanical components The SUSTAPEEK 3D printer build surface is suitable for common fused deposition modelling applications such as early prototypes, model making and the industrial production of mechanical components and spare parts. “In particular, prototypes in the early stages can be developed even faster with a 3D printer build surface made of SUSTAPEEK, since the time for surface processing is no longer required. Printers can concentrate even more on optimising the design and functions of their components”, explains Maurer. Avoid warp effects At the same time, the strong adhesive effect of SUSTAPEEK in combination with the highly homogeneous surface contributes to avoiding the warp effect and thus supports the reliable production of components. Thickness of just 1 mm enables excellent heat transfer The 3D printer build surface made of SUSTAPEEK isavailable in thicknesses from 4 mm up to 1 mm. This very low thickness enables particularly good heat transfer. Components can thus be produced very reliably. Suitable for a wide range of filament types The SUSTAPEEK 3D printer build surface is suitable for various common filaments such as ABS, PLA and PET, but also for high-performance materials such as PEEK and PEI. The time-consuming swapping out of the 3D printer build surface for the use of different filaments is not necessary. The fastening can be done with staples or heat-resistant, double-sided adhesive tape. High temperature resistance Thanks to a continuous operating temperature of up to 250 °C and a short-term maximum operating temperature of up to 310 °C, the SUSTAPEEK 3D printer build surface withstand unintentional contact with the printer nozzle. A conventional 3D printer build surface is quickly damaged by contact with the nozzle and may have to be replaced. Long service life and clean printing bed The finished printing object can be easily removed from the build surface with a spatula. With the high wear and scratch resistance of SUSTAPEEK, the build surface has a very long service life and an visually high-quality surface. After printing, the surface can be easily cleaned with standard cleaning agents and thus offers a permanently clean printing bed. Supply range 3D printer build surface made of SUSTAPEEK: • Thickness: 1-4mm • Format: up to 3000 mm x 1000 mm • Also available in individual shapes and sizes