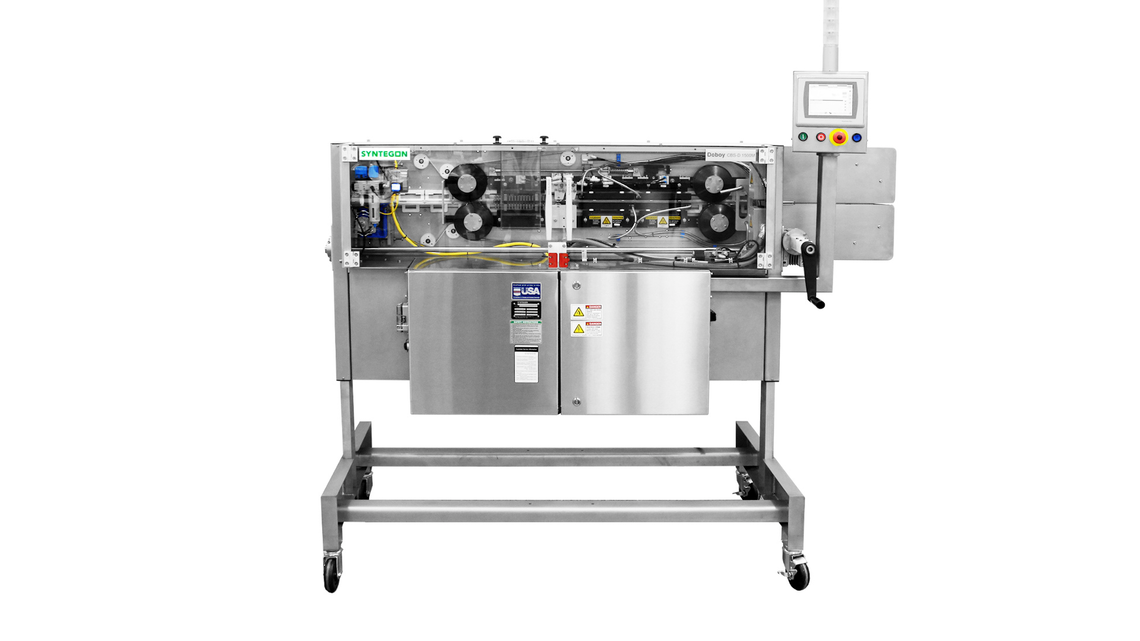

Syntegon Technology, a process and packaging technology provider, is launching its redesigned continuous band sealer machine range. The Doboy CBS-D and B-550 have new names–CBS-D 1500 and CBS-D 750, respectively–and are designed to feature improved operability in combination with the technology of their predecessors.

“Our CBS-D machines still feature the same sealing technology,” says Kelly Meer, product manager at Syntegon Technology. “With this upgrade, we are opening a new chapter in terms of user friendliness and machine integrity.”

The redesigned machines include:

- CBS-D 750 with a 7.5-inch heat bar and CBS-D 1500 with two 7.5-inch heat bars,

- Standard stainless-steel execution used for hygienic design,

- Improved user interface and additional design features meant to ensure convenient operation, and

- CBS-D medical version with Allen-Bradley standard touch screen.

Hygienic and user-friendly design

All CBS-D machines now come with a stainless-steel machine frame as standard. This hygienic design feature is supposed to enable the use of the CBS-D in hygiene-critical production environments. The CBS-D 750 with a 7.5-inch heat bar and the CBS-D 1500 with two 7.5-inch heat bars (15 inches in total) also have an updated machine design.

“The previous models not only differed in terms of heat bar length; they were also constructed differently,” Meer says. “We have redesigned the machine components and now offer a fully modular structure.” This is meant to allow customers to configure the machines based on their specific needs.

The CBS-D machines have also been upgraded in terms of user-friendliness:

- Their height is ergonomically adjustable to simplify the bag infeed.

- The polycarbonate guards are designed to let more light into the working cell for easy access to the sealing unit by operators. This is meant to facilitate machine operation and maintenance.

- The HMI interface can be adjusted flexibly for horizontal and vertical machine use.

Medical sealing

The continuous band sealers also come in medical versions–designed to meet the medical packaging validation requirements for products to be sterilized. The Doboy CBS-D 750 M and 1500 M are made to offer direct access to the test ports for faster and simple validation and machine calibration. For these medical configurations, the user-friendly HMI interface now comprises a standard Allen-Bradley display that is designed to regulate temperature, pressure and speed. The integrated medical pneumatic control system includes a Festo FLR unit with a digital display regulator for easy maintenance and control.