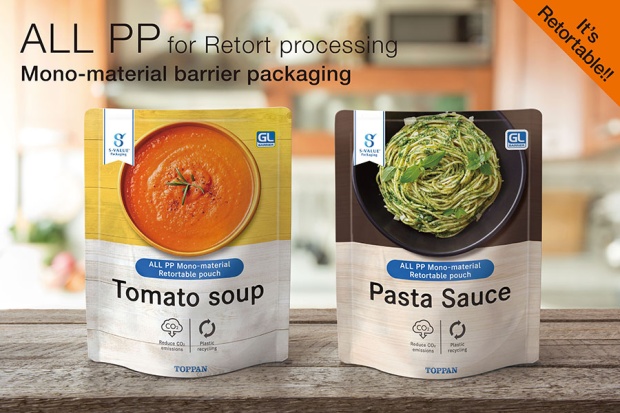

Toppan, a global leader in communication, security, packaging, décor materials, and electronics solutions, has added to its comprehensive range of GL BARRIER brand products centered on transparent barrier films by developing new polypropylene (PP) mono-material barrier packaging with outstanding heat and water resistance, making it suitable for retort sterilization.

The new packaging takes advantage of GL BARRIER's vapor deposition and coating technologies to provide the heat and water resistance needed for retort sterilization, something that has proved challenging with conventional PP films. This means that packaging with mono-material compositions for enhanced recyclability can now be used for retort foods. In addition, the absence of metal in the packaging enables microwave heating and the use of metal detectors to check for foreign objects.

This adds further to the lineup of GL BARRIER products that meet growing demand for mono-material solutions, particularly in Europe and North America. Toppan will supply ALL PP packaging to food manufacturers and customers in a wide range of other industries. Samples will be available globally from spring 2023, with sales targeted for launch within the same year.

The key concept for Toppan's Medium Term Plan, which was published in May last year, is Digital & Sustainable Transformation. One of the priorities identified is responding to global demand for sustainable packaging and accelerating the establishment of a network enabling local production for local consumption.

In 1986 Toppan developed GL FILM, a barrier film that can help address challenges faced by international society, such as the need to reduce food loss and resource consumption. GL FILM is widely recognized for its eco-friendliness and resource saving. Today it enjoys the leading share of the global market for transparent vapor-deposited barrier films on account of its world-class barrier performance and an extensive lineup of products for diverse purposes.

Efforts to circulate resources from packaging waste are underway in the EU, with a target to make all packaging reusable or recyclable by 2030. Employing mono-material compositions for packaging is an effective way to improve recyclability, and there is demand for barrier films and packaging for PP-based mono-material packages. By developing ALL PP mono-material barrier packaging with the superior heat and water resistance needed for retorting, Toppan has made it possible to shift to mono-material structures for retort food packaging.

Features of ALL PP mono-material packaging

・PP mono-material composition for enhanced recyclability

Toppan has achieved excellent recyclability by switching to a PP-based mono-material composition.

・Suitable for retort sterilization

Vapor deposition and coating technologies accumulated in the development and manufacture of GL BARRIER products have been leveraged to create a PP film that delivers barrier performance as well as water and heat resistance that have previously been difficult to achieve. Combining PP barrier film with advanced coating know-how has enabled barrier packaging with a mono-material composition that takes advantage of PP's heat resistance.

・CO2 emissions reduced by switching from aluminum foil

CO₂ emissions during manufacture can be reduced by approximately 26%2 if the new PP-based mono-material packaging is adopted as an alternative to conventional multi-material packaging that uses aluminum foil.

Toppan plans to expand sales of this and other mono-material packaging products as it works to contribute to a sustainable global society.