Our efficient tracking and automation solutions save our clients time, money, and labor. Modern technology enables products to be shipped from all corners of the world with seamless management of the relevant information (such as their location throughout the process, their target country, and the date of delivery). It is now possible to automatically track the location and shipping status of every single pallet and crate and manage them effectively as if they were the only ones in the warehouse.

Tracking and automation solutions benefit everyone. End customers can independently follow every step of the shipping process. The products reach their destination intact and on time, and you can identify bottlenecks and failures in the logistics systems, which would help you improve your service and save costs.

To help you familiarize yourself with the different tracking options and choose the most suitable solution for your needs, we have compiled everything you need to know about the different tracking technologies and solutions which can be embedded in our packaging products.

Identification and tracking through radio frequency – this advanced solution enables you to identify and track crates and pallets automatically. How does it all happen? Each product is equipped with a unique chip, which is embedded on a sticker or planted in a designated area on the product. The chip stores all the information about the crate or the pallet: its contents, shipping dates, destination and other details. This information can be read by electronic devices with antennas. With these readers, relevant workers such as forklift operators and warehouse staff can easily obtain the shipping details of each product. For this solution to be effective, staff members at all stages of the shipping process will need to have the right equipment for reading the information and linking it to the organization’s databases.

Technologies that use radiofrequency:

RFID – embedding RFID technology in crates and pallets is a cheap way to control the logistic process. It gives businesses a strategic advantage by enabling them to track their stock along the chain of supply more efficiently and provides visibility and information on business processes in real-time.

NFC – Near Field Communication. This technology is based on the RFID technology and uses a device embedded in the crates/pallets, which sends radio waves to a passive electronic device for the purpose of identification, verification, and tracking. It’s an effective solution when there is no need to obtain information while the goods are in transit, but rather just from within a logistics center, where both devices are relatively close to each other.

Barcodes – embedding a barcode is a relatively cheap solution for managing information about products, including their location throughout the process, the destination country, and the time of delivery. Adding a barcode makes it possible to automatically track the location and shipping status of every single crate/pallet as if they were the only ones in the warehouse.

There are a number of ways to add a barcode to packaging and shipping solutions:

– Barcode sticker – a sticker can be added or replaced at any time and is fully resistant to processes of washing and disinfection and to UV rays

Imprinting a digital barcode – this involves inserting the barcode to a digital device. The information is printed on a ribbon, and a hot press transfers the barcode onto the product. This process gives you a wide choice of colors, and because printing is done digitally, we can change the artwork from one crate to the next, which is useful for adding crate numbering and for other purposes. The process of digital imprinting means that the barcode becomes part of the crate, and cannot be removed.

– Imprinting a multi-color barcode on the surface of the crate/pallet – a colored ribbon is placed between the product and the plate, and the plate is pressed to the desired area of the crate or pallet. The raised parts of the heated plate transfer the dye and imprint it onto the surface of the product. The result is a high-quality, eye-catching imprint on the surface of the product.

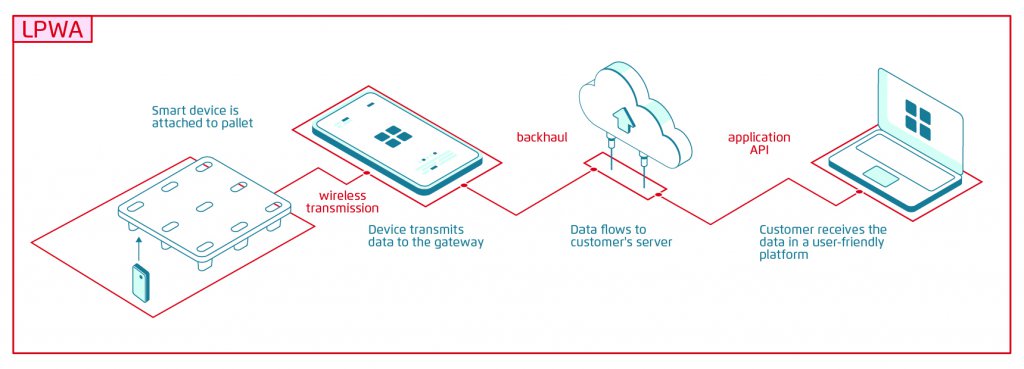

LPWA-based technology – (Low power wide area)

This technology enables tracking using low-energy sensors while monitoring environmental variables that are useful for you such as temperature, humidity, movement, etc. This system is implemented by embedding a smart, low-cost device with long battery life in the plastic surface of the product. The device sends you online alerts according to predefined criteria, which allows you to identify and solve problems in real-time. The information generated by the system enables you to identify bottlenecks and failures in the logistics system, which would help you improve your service and save costs.