Giant cardboard boxes, puffy plastic air pillows, Styrofoam, packing peanuts, polystyrene bags, and plastic wrap. Consider, too, what’s discarded from consumables: tray liners, clamshells, egg and milk cartons, and plastic soda bottles, to name a few.

We’re drowning in packaging — some 82.2 million tons of it is produced annually in the United States alone. Our pollution problem isn’t only about the stuff we consume, it’s the stuff around the stuff that we consume. While packaging materials tend to be short-lived in our households before heading to the landfill, they’re waste products that are likely to stay there for close to eternity, or else become litter that eventually finds its way into the ocean.

That realization hit home for Rich Cohen, who hatched a business plan for more sustainable packaging while on a year’s sabbatical from his corporate job some 20 years ago. Wherever he traveled, there was evidence of our planet’s packaging problem, and he recognized that the industry didn’t have any incentive to move to less wasteful and polluting material at the time. Inspired to help, he launched Chicago-based Elevate Packaging, which describes itself as the first company focused exclusively on making sustainable packaging materials — compostable bags, mailers, labels, and shrink-wrap.

Cohen was early to perceive a trend that in the last few years has become a worldwide phenomenon: Companies are making the switch from conventional packaging materials to ones that have a reduced carbon footprint, require less energy to manufacture, and produce less pollution. The trend has taken root in the last decade as the threat of global warming and the deluge of ocean plastic have awakened the public to the urgency of environmental protection.

Packaging innovation accelerated during the pandemic as consumers leaned into online shopping and then had to live with the accumulated boxes, bags, and packing peanuts. “Post-COVID, the growth rate of [the sustainable packaging] industry went up by three times,” says Ismail Sutaria, chief research analyst of packaging at the research firm Future Market Insights. The company expects that, over the next decade, the sustainable packaging materials sector — currently worth $274 billion a year — will grow worldwide at a compound annual growth rate of 5.4%. In 10 years it will make up 30% of the total packing materials market, up from 20% today, according to Sutaria.

Currently, the sheer quantity of packaging generates a tremendous environmental impact, but there are ways to reduce it. The first is simply to produce less, for instance by redesigning packaging so that it involves less material. The second is to cut down on resource extraction by using recycled material and by producing packaging material that itself can be recycled. And the third is to produce material that can be composted or otherwise returned to the environment in a non-polluting way.

Not only is there a growing market for such solutions but increasing pressure from regulators, as well. Recent years have seen a spate of new rules regarding packaging waste around the world; among the countries in the lead are Belgium, Brazil, Argentina, and India. In the United States, Maine, Oregon, Colorado, and California have all enacted legislation to reduce packaging waste. California’s Plastic Pollution Prevention and Packaging Producer Responsibility Act, for instance, requires all single-use packaging in the state to be compostable or recyclable by 2032.

HP has made significant strides in reducing single-use plastics in primary packaging for personal systems and printer hardware. In 2019, the company set a goal to eliminate 75% of single-use plastic packaging by 2025, compared with 2018. In 2022, HP achieved a 55% reduction from 2018 levels.

“Packaging plays a crucial role in the sustainability of our products, as it safeguards them during transportation,” says Wei Zhao, director of worldwide packaging design & procurement at HP. “However, we know that excessive or inefficient packaging can contribute to unnecessary waste and resource consumption.”

HP is eliminating needless packaging material and hard-to-recycle materials such as plastic foam; innovating new packaging designs to use materials with lower environmental impact, such as sustainable fiber and recycled plastics; and prioritizing recycled content and easily recyclable materials, such as molded fiber. Also known as molded pulp, molded fiber packaging is typically composed of recycled paperboard and/or newsprint but can also be made from many plant cellulose fibers, including bagasse, bamboo, and wheat straw.

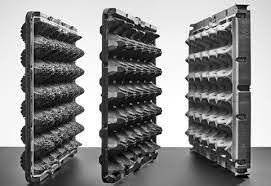

HP’s Molded Fiber Advanced Tooling Solution, a business that HP launched in 2020, leverages Multi Jet Fusion 3D printing technology to engineer customized tools for molded fiber production for specific applications. The result is biodegradable and recyclable packaging that can be tailored to protect almost any shaped product during shipping and handling, from food containers and household items to electronics and single-use medical devices. HP uses its own tooling technology to produce molded fiber packaging to ship some of its toner products and the HP Desktop Mini lineup of PCs.

“Sustainable molded fiber alternatives not only minimize waste but also enhance recyclability and circularity,” says Zhao. “Through the implementation of molded fiber packaging solutions, we are making significant strides in achieving our sustainability objectives while addressing the global challenge of plastic waste.”

Not only is HP using molded fiber to package some of its own products, it’s helping its customers create custom packaging to enhance their production process and make it more sustainable. Omni-Pac Group, a French company that started out producing egg trays made from recycled newspaper in the 1970s, today manufactures a wide variety of molded fiber packaging materials for agriculture and other industries, including egg trays for mass shipping. The company is a major manufacturer of wet molded fiber in Europe, sourcing wastepaper from municipal recycling centers, which is then shredded and mixed with water to form a papiermâché-like blend. “We pride ourselves on having green products,” says Omni-Pac CEO Pablo Libreros. “They’re made out of recycled paper, and the products themselves are recyclable and compostable.”

Omni-Pac taps HP’s Molded Fiber Advanced Tooling Solution and leverages its expertise in fluid dynamics to optimize the thickness and weight of the finished packaging, while minimizing water usage and waste. Using digital manufacturing to 3D print the tool to exact specs not only speeds up the whole manufacturing process but also makes it more efficient to create a single mold on demand.

“HP has the capacity to do great simulations about how the fibers are going to behave based on the shape of the mold, and then optimize the final result,” Libreros says. “That’s allowed us to significantly reduce the amount of fibers that are needed to manufacture our products. We’re aiming to save 10% to 15% of CO₂ emissions through these process improvements.”

Sustainable packaging materials have made the biggest inroads in the food and beverage industries, followed by cosmetics, consumer electronics, and healthcare. “By embracing the versatility of molded fiber, our solution can revolutionize packaging across industries,” says Mariona Company, head of molded fiber-based packaging solutions at HP. “It’s our shared responsibility to push boundaries, think creatively, and identify new applications.”

The trend is also extending into developing countries, as the health of the planet is an increasingly urgent issue of worldwide concern. In Latin America, molded fiber packaging producer Gualmosa (part of Molpack) is using HP’s Molded Fiber Advanced Tooling Solution at its factory in Guatemala to manufacture trays out of recycled paper for shipping fruit. Tests are currently underway, and the company aims to introduce the product across its lineup by year’s end, says Ana González, Molpack’s chief of quality.

The company had tried to launch a similar project in the past, but they faced challenges in a hot Central American environment. Explains Gonzalez, “It was biodegradable, and it couldn’t resist humidity and high temperature.” This time around, Molpack will have the advantage of computer modeling and design and HP’s 3D-printed molds, and it will likely add a nonbiodegradable liner to protect the recycled fiber from moisture.

The fact that packing materials sometimes have to be handled in a certain way to reap their environmental benefits is an underappreciated aspect of recyclable and compostable material. Years ago, Elevate’s Cohen noticed that a lot of biodegradable materials were inadvertently being rendered non-compostable because of something as small as a sticker. While to a casual consumer the sticker might seem like a small thing, it was effectively contaminating the process. “Commercial composting operators were complaining because they were getting all this material contaminated with plastic, and instead of making compost with it, they were having to send it to a landfill,” says Cohen.

Cohen came up with the idea of creating labels that were compostable, too — “the world’s first pressure-sensitive adhesive label material,” as he puts it. Elevate also makes bioplastics out of plant material that, while they look and function like normal plastic film, are actually biodegradable. The company’s clear compostable cellophane bags are made from sustainably harvested wood fiber that is chemically dissolved and extruded into sheets before being dried and coated.

As sustainable packaging materials go mainstream, they not only help consumers and producers feel good about their choices, but they also invite a new generation of innovators to rise to the challenge. Today, all sorts of exciting new approaches are reaching the market. In place of Styrofoam peanuts, shippers can now use sustainably produced and compostable materials like coconut husks and mushroom-based packaging. Another successful innovation is materials like foam packing sheets and packing peanuts made of cornstarch that are used by the shipping materials giant Uline and dissolve under running water.

By 2050, experts say, sustainable materials could make up the majority of all packaging. But at present the sector’s growth is constrained by several factors, not the least of which is cost. Molpack’s compostable fruit trays, for instance, cost twice as much as plastic ones.

“Consumers are very happy to spend an extra penny to invest in packaging that is eco-friendly and sustainable and that is going to help the environment,” Sutaria says. “But if this is going to be commercially accepted worldwide on a mass scale, the price differential will have to be balanced. And doing that will depend on continuing innovation.”

The process of mainstreaming sustainable packaging will involve successes and failures. As the saying goes, you can’t make an omelet without breaking a few eggs. “If you want to have big returns, you have to take risks,” says Omni-Pac’s Libreros, adding: “We hope we won’t break any eggs.”