Before an airplane is assembled, its components must be manufactured and shipped to the assembly plant and sometimes stored. This critical period can lead to the uneventful arrival and installation of a propeller or engine, or it can lead to headaches and setbacks from corroded components. Cortec® Corporation encourages man-ufacturers to take the first option by choosing a simple but effective packaging strategy based on Vapor phase Corrosion Inhibitors.

Corrosion Dangers During Shipping and Storage

Shipping and storage are vulnerable times for aircraft components, especially when they take place in a hot, humid environment or undergo fluctuating temperatures during export. These provide ideal conditions for corrosion to form as moisture condenses on metal surfaces inside packages and heat accelerates the corrosion process. Manufacturers and end users may be left with corrosion damage and stains that mar appearances and call component integrity into question.

Effective Protection Minus Greasy Rust Preventatives

VpCI® packaging methods rely on Vapor phase Corrosion Inhibitors to eliminate corrosion in a way that keeps aircraft components dry and ready-to-use. As long as the aircraft component remains enclosed with a sufficient supply of Vapor phase Corrosion Inhibitors, it will be protected by a corrosion inhibiting layer that adsorbs on the metal surfaces. Once the component is removed from the packaging, this molecular layer begins to dissipate on its own—no cleaning of messy rust preventatives typically required! Vapor phase Corrosion Inhibitors come in a variety of forms, from VpCI® film and paper to emitters and fogging fluid.

Aircraft Component Packaging Scenarios

VpCI® packaging can take many different shapes depending on the component type and shipping or storage parameters. The following are a few possible packaging scenarios.

Propeller Packaging

Propellers can be protected by wrapping CorShield® VpCI®-146 paper (a USDA Certified Biobased Product) around sensitive areas and heat shrinking each propeller in VpCI®-126 Shrink Film before shipping to the customer.

Engine Packaging

Special crates and frames used to hold engines in place for transport can be lined with a VpCI®-126 gusseted bag before placing the engine inside. Desicorr® VpCI® Pouches with a combination of desiccant and Vapor phase Corrosion Inhibitors can be added to the bag for dual moisture absorption and active corrosion inhibition. For engines heading to especially hot, humid regions, a light spray of EcoAir® 337 can be added for extra corrosion protection just before the package is closed.

Electronics Packaging

Avionics that play such a major role in aviation today may need protection against ESD (electrostatic discharge) damage as well as corrosion. For this purpose, electronics manufacturers can package avionics in EcoSonic® VpCI®-125 HP Permanent ESD Film & Bags, which contain both corrosion inhibitors and an inherently static dissipative component.

Helping Global Aerospace Leaders

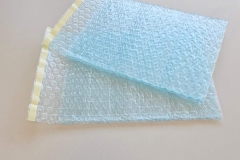

Of special note among recent applications, Lake Engineering Solutions reported in 2024 that a global aviation leader in the UK had enhanced its packaging process by adopting Cor-Pak® VpCI®-126 Bubble Bags powered by Nano-VpCI™. This improvement streamlines the protection of parts against corrosion and mechanical damage, allowing the OEM to use one packaging material instead of two (i.e., regular bubble bags + VpCI®-126 bags). Additionally, Lake Engineering helped a UK division of another of the world’s largest aerospace manufacturers reduce their plastic footprint by implementing Eco Wrap® (certified ‘OK Compost INDUSTRIAL’ by TÜV Austria) the previous year. After testing it with their logistics team, the OEM decided to use it as a direct replacement for the LDPE stretch wrap they had been using for internal shipment of components.

By implementing packaging strategies such as those suggested above, aircraft component manufacturers can eliminate corrosion problems during shipping and storage, develop peace of mind and happy customers, and sometimes even find ways to improve their environmental profile. Contact Cortec® for guidance on the best packaging strategy for your aircraft component export or storage scenario.