The Group is preparing for the biennial Parma fair – Hall 3 #D026 - with its latest technological offerings, from bag-in- box filling systems to the new range of KUBE modular labellers, characterised by unique versatility and flexibility. Moreover, automated end-of- line solutions for all food pack types will be on show. In short: an all-round technology and service partner for the food&beverage industry.

Like a well-orchestrated symphony, Sacmi-designed bag-in- box packaging solutions stand out on account of their harmonious linearity, reliability and high level of automation. A true technological “show” that potential international investors can see for themselves at the two- yearly Cibus Tec HALL 3 # D 026 (25-28 October 2016, Parma). This fair is one of the world's key technological innovation events for the food industry and is expected to attract at least 30,000 visitors from 35 countries.

Automated aseptic and ultra-clean filling

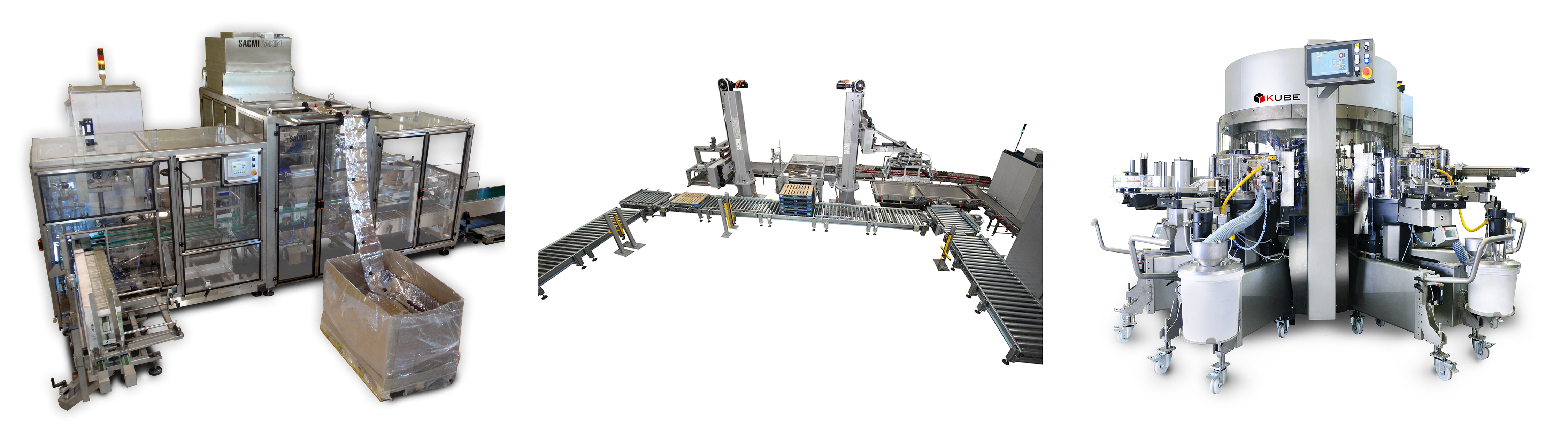

n innovative Sacmi filling monoblocs every stage is designed to enhance both product quality and user-friendliness; this is achieved by using advanced, stainless steel filling valves and an automatic sanitising system that ensures perfect integrity of all product types plus outstanding output rates of up to 960 bags per hour in the 3-litre ultraclean format. Case forming, aseptic/ultra-clean filling and bag closing are fully automatic and executed in a single passage through the machine, making it the most efficient solution for one-step processing, from raw material to finished product, sealed and ready for palletization.

Flexibility and performance with the new range of KUBE labellers

Designed to offer maximum flexibility of use on an ever-evolving market, the new range of KUBE modular labellers is characterised by a hard-wearing, compact structure (made entirely of stainless steel) to which labelling units are connected outside the turret. This allows utilisation, in parallel, of different label application technologies (self-adhesive, hot glue and cold glue) with just one passage through the machine. On the new KUBE, unique levels of versatility are combined with very easy use and maintenance thanks to the modular structural configuration, designed to ensure easy access to vital machine parts.

From flexi pack processing to automated, integrated end-of- line solutions

Machines and complete plants for the efficient, integrated management of flexi packs: the Sacmi Packaging answer to a market trend in which demand for such packs is growing at a rate of nearly 10% a year Capable of compatibility with a broad range of technologies – vacuum, gripper, side load etc. – to ensure optimal handling of such packs, Sacmi’s plant engineering solutions range from filling to case packing, from palletizing to end-of- line solutions.

A high degree of process automation allows efficient control via Pick&Place robots plus effective pack handling, not to mention high output rates in the order of multiples of 150 doypacks per minute in various formats. All stages – handling, case packing, palletization – can be rendered fully automated and efficient whatever the food pack type, from flexi packs to plastic cartons and glass jars, from doypaks to HDPE bottles and yoghurt/dessert cartons.

All-round plant engineering for the beverage industry

A manufacturing and service company with branches on five continents, Sacmi completes its technological and plant engineering solutions for the industry with a fast-response, far- reaching after sales assistance service. Moreover, all solutions are designed and tested at the Beverage R&D lab, a facility certified by top international players that is pivotal to all Sacmi's work within the industry.

Through its Automation&Service Division, the Group also provides integrated inspection and quality control systems for every stage of the beverage production process, from label to container, from preform to cap. This broad range of solutions allows Sacmi to act not just as a supplier of cutting-edge individual machines and complete plants from a technological standpoint, but also as a partner-provider of complete, integrated total quality control systems for every stage of production.