The countdown towards Italy’s biggest fair in the industry – to be held at Rimini Fiera for the second consecutive year – has begun. A starring role will be played by Sacmi’s complete, automated fruit and vegetable packaging solutions, which offer the very best productivity and flexibility on the market

Against the backdrop of steadily rising fruit and vegetable purchase volumes in Italy (+ 3% compared to the previous year) and a production that, after years of shrinkage, is now back above 8 million tons (source: Macfrut Consumers' Trend), the international Macfrut fair is preparing for its second consecutive year. Following the usual preview at Rimini Wellness, Macfrut will be held at Rimini Fiera (14 th -16 th September 2016); its main focus will be process and product innovation.

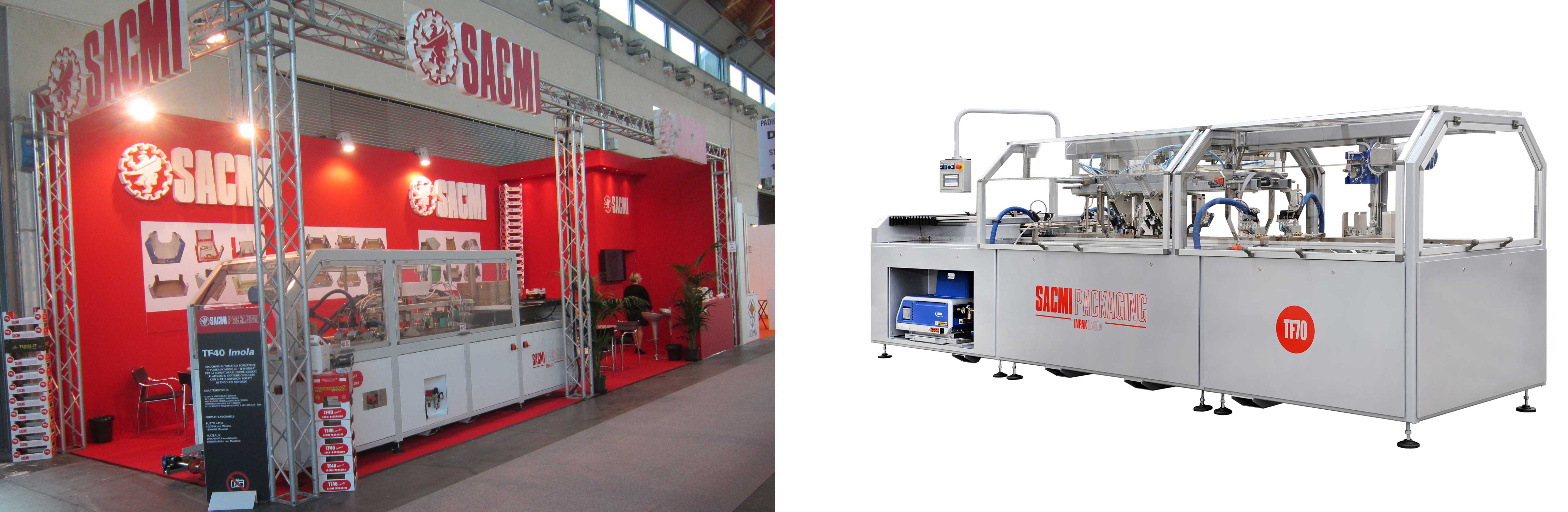

This is the perfect showcase for Sacmi Packaging - Pad 1, #187, which will be in Rimini, on an 80m 2 stand, to exhibit its cutting-edge technology for the sector: machines and complete plants for fruit and vegetable packaging that offer high productivity, automation of pack forming and end-of- line tasks plus flexible management of different formats. The target: the more than 39,000 visitors expected to flock to the 33,000 m 2 exhibition area.

At the core of the Sacmi Packaging range lies the TF series of automatic forming machines. These range from the TF40 Imola (appreciated by the market on account of high productivity, flexibility and efficiency) to the TF12 EVO, an automatic forming machine for open-top trays and standard trays with top flap or side doubling that again provides excellent high productivity (up to 40 trays/minute), quick size changeovers (from 5 to 15 minutes), simple machine management and easy setup via the colour control panel. Last but not least, the TF70 is currently the most competitive, highest-performing solution for the assembly of open and closed corner trays (up to 55 pcs/min thanks to the double feed chain).

From the TF series we move on to the GD25, a Sacmi Packaging former configured for the assembly of various pack types such as open-corner trays and boxes with outer corner reinforcement. Characterised by flexibility and durability, this solution has been made even more versatile in 2016 and is designed to handle a wide range of corrugated cardboard trays at rates of up to 45 pcs/min depending on the format being processed.

Low maintenance, user-friendliness, quick size changeovers, a wide choice of optional equipment to efficiently manufacture all commercially available tray types: all features shared by every Sacmi Packaging automatic former, all designed to operate in line with mechanical stackers to allow fully automated machine outflow management and the creation of assembled box batches. Such stackers include the TS43 Imola, available as of late May 2016, supplied with the Imola TF40, TF12 EVO and GD25 formers, and the new TS60, redesigned by Sacmi to keep pace with the high productivity of the TF70 to allow parallel management of twin tray stacks up to a length of 800 mm and with unlimited stack height.

Forming machine magazine loading tasks can be handled efficiently using the automatic BF13 loader (together with the TF12 EVO, TF40 Imola and GD25) or the BF23 (in combination with the TF70), two devices that, by feeding the forming machine automatically, minimise the need for operator intervention and optimise loading of horizontal blanks into the machine.