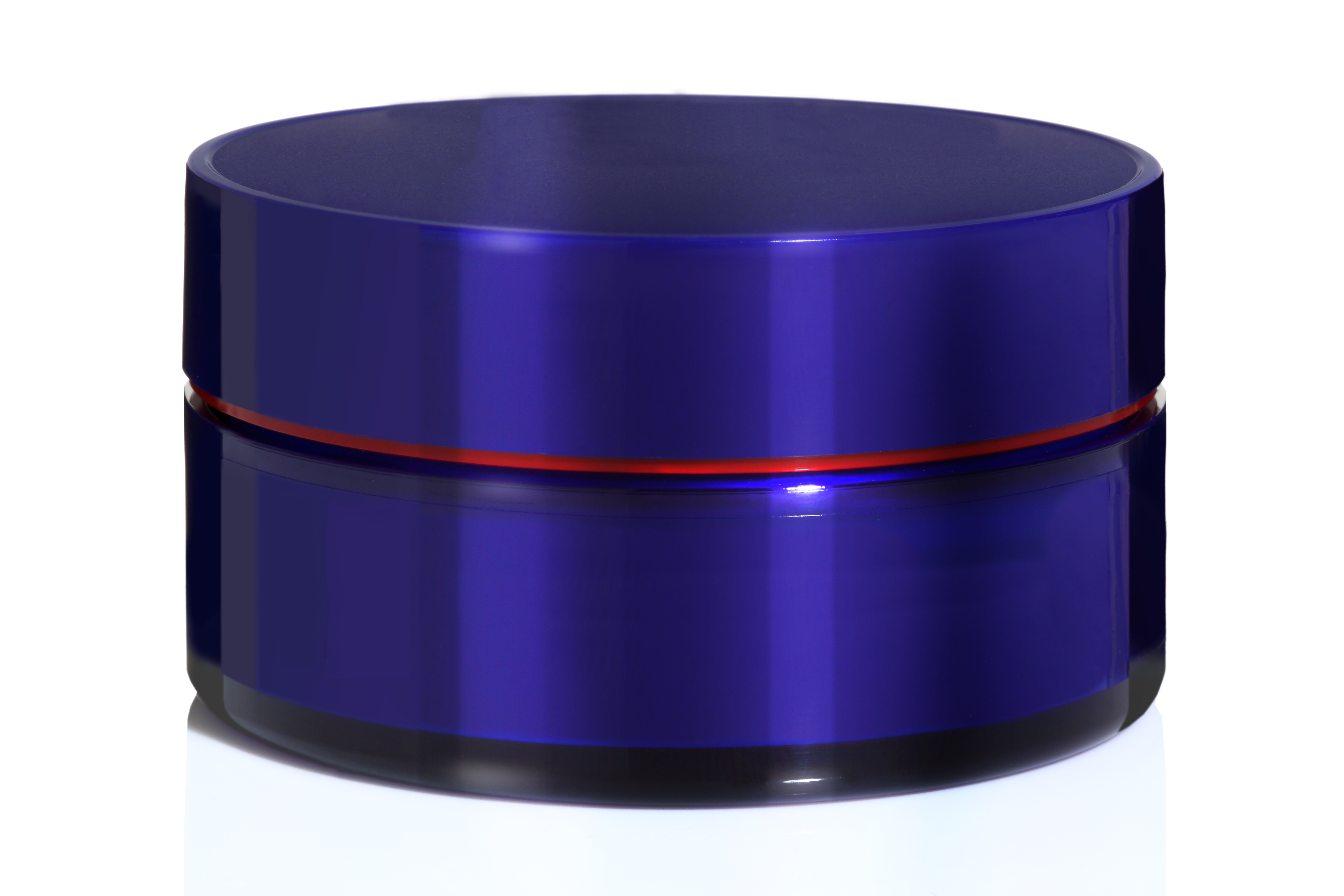

Cutting-edge technology creates luxury packaging for the global leader in the skin care market and provides on-shelf appeal. Global Closure Systems (GCS) manufactures new bi-injected plastic jar packaging which replace glass packs. The shatterproof jars have been designed to improve consumer safety while maintaining the aesthetic appeal of the product and brand recognition. Substituting plastic for glass offers practical advantages both for the end user and the supply chain. The new design is also more efficient to produce, which supports GCS’ customer objectives to reduce its overall carbon footprint. To replicate the luxurious look and feel of the old glass containers, GCS leverages its expertise in biinjection and cube technology to manufacture a double-walled jar composed of two layers – the inner part is opaque, the outer is translucent. Both the PP and the PET jars are supplied by Bender, GCS’s production plant in Frankenthal/Pfalz, Germany, which has invested in separate and complex injection-moulding and packing lines that can produce the product at high volumes and therefore more cost-effectively. Shorter cycle times are possible as individual steps in the manufacturing process, such as mold filling and the cooling phase, are carried out simultaneously thanks to the cube-technology. Thanks to its proficiency in cutting edge technologies with a keen sense of market trends, GCS can assist the FMCG companies with the whole process of a new product launch - designing, prototype tooling for market research, product approval and building the moulds in-house or working closely with the leading mould makers to start production in a swift and seamless way. GCS also enables quick and worldwide product launches.