Reifenhäuser Blown Film will be showcasing technical solutions for the economical and sustainable production of blown film that pay off in terms of a functioning circular economy and reduction of the carbon footprint at the new GREENPLAST 2022 congress trade fair in Milan from May 3 to 6 (booth 14 P / A38). Highlights include the patented EVO Ultra Stretch production process for fully recyclable All-PE Blown Film, the use of digital product passports in the interests of a functioning circular economy, and technologies for the economical processing of post-consumer and postindustrial recyclate. The blown film plant specialist is thus showcasing examples of future-proof technologies that are consistently designed for the production of sustainable products.

Recyclable packaging thanks to EVO Ultra Stretch

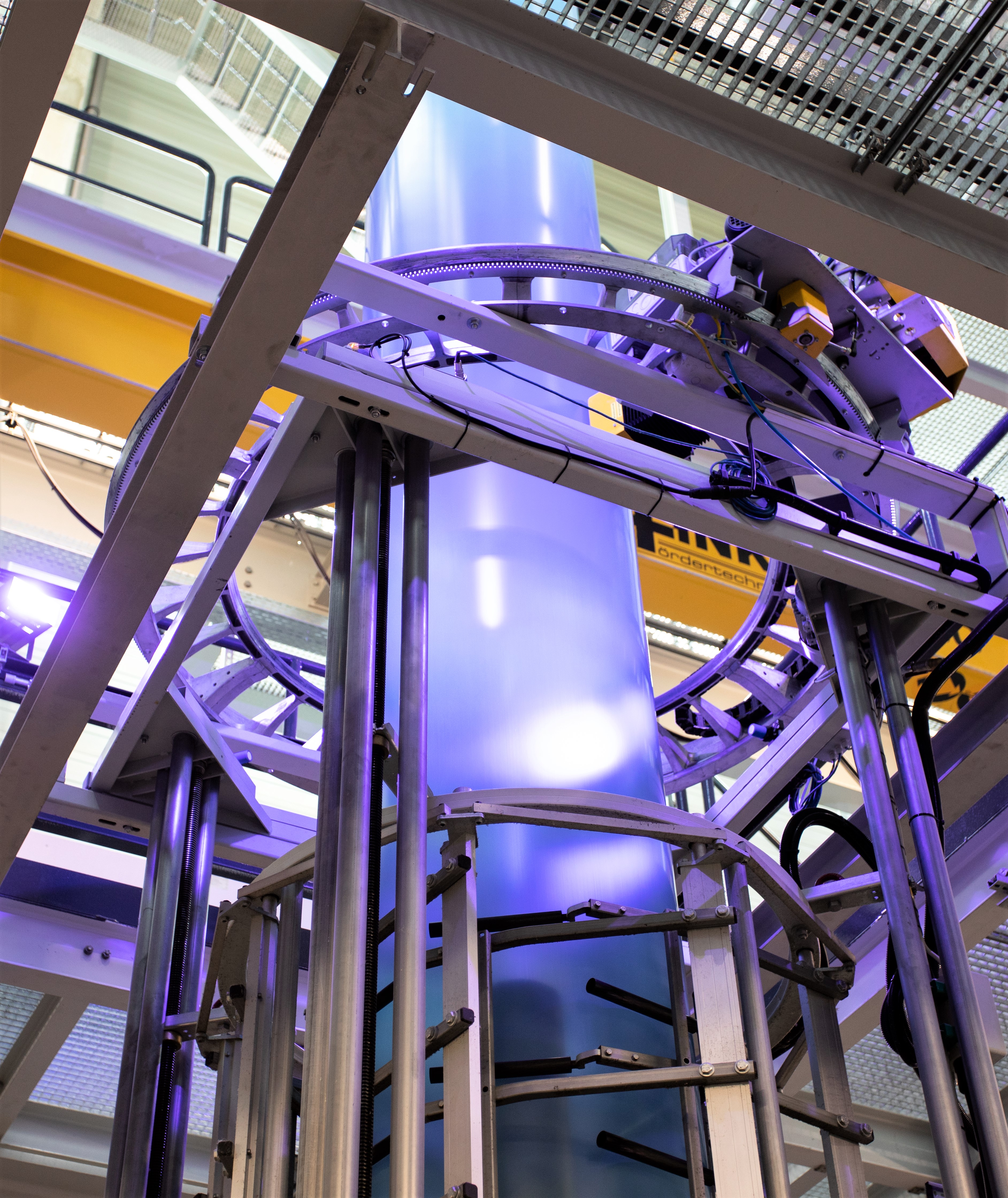

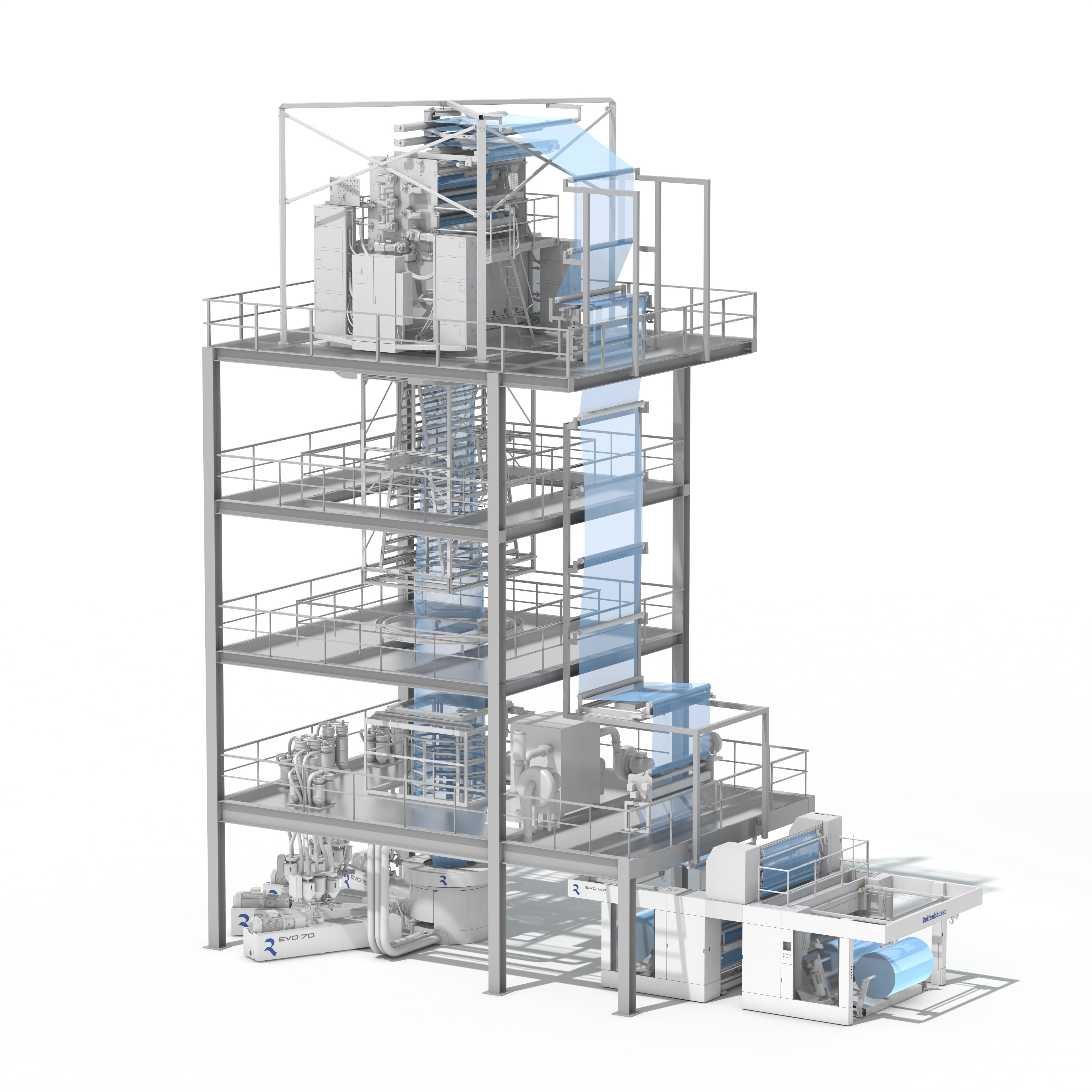

EVO Ultra Stretch, Reifenhäuser's patented stretching unit, enables the production of mono-material composites (All-PE Film) for fully recyclable flexible packaging in which the otherwise usual PET layer of the packaging is replaced by stretched PE. This is made possible by the maximum 10-fold stretch rate, which gives PE films completely new mechanical properties. There is no need to adapt further processing steps such as printing, laminating and converting. Thanks to the patented position of the stretching unit directly in the haul-off of the blown film line, the film is stretched at the ideal time and from first heat, which at the same time makes the process particularly user-friendly, stable and efficient. Sascha Skora, senior sales manager at Reifenhäuser Blown Film, explains: "We supply our customers with production lines that enable them to now use the sustainability shift as an opportunity to become a preferred supplier for new, recycling-friendly products that serve the environment and business success."

Digital product passport enables circular economy

To make the best use of the potential of fully recyclable packaging for the circular economy, Reifenhäuser relies on digital product passports via RCycle - the traceability standard for plastic packaging. At Greenplast, Reifenhäuser will show a fully recyclable ALL-PE pouch equipped with this technology.

R-Cycle automatically stores recycling-relevant information during production and makes it available as a standardized data record for the waste sorting process. This enables data-based and thus more precise sorting for high-quality recycling. Production machines along the entire value chain can thus record relevant data, such as the type of plastic, printing ink, adhesive, additives and also the use of the packaging (food / non-food), and make this information available on the end product via appropriate marking (e.g. digital watermarks). R-Cycle was developed to market maturity by various technology companies and organizations along the entire life cycle of plastic packaging. Reifenhäuser is a founding member of the cross-industry community that aims to establish digital product passports to build a functioning circular economy worldwide.

Lowest-quality recyclate processing with EVO Ultra Fusion

High recyclate content in packaging is just as important as recycling-friendly design of plastic products. However, manufacturers face new technical challenges in processing recyclates: The highly fluctuating quality of the input material is one of the biggest problems. With the Reifenhäuser EVO Ultra Fusion extrusion process, blown film producers make themselves less 3/5 dependent on the input quality and can also dispense with the energy- and cost-intensive regranulation of the recycling material. Fluff (film shreds) as well as all types of production waste and PCR material can thus also be extruded directly. Ultra Fusion processes even the lowest quality recyclates, which were previously out of the question for the blown film process, into functional films for applications such as trash or mailing bags. This is made possible by twin-screw technology, for a better melt homogenization, which ensures a stable process. Processors can also degas the system very easily and effectively, removing unwanted ingredients in the recyclate.

For processing better quality regranulates, Reifenhäuser recommends the already well-known EVO Extruder in the 33L/D variant. Thanks to optimized barrier as well as shear and mixing parts, this extruder processes recycled material as reliably and naturally as other raw materials - the ideal prerequisite for success in the growing market for products with a high recycled content.

About the Reifenhäuser Group

The Reifenhäuser Group is the leading provider of innovative technologies and components for plastics extrusion. Founded in 1911, the company supplies high-technology solutions all over the world. With its technologies and the know-how of its 1,750 employees, Reifenhäuser has the world's largest network of expertise in plastics extrusion technologies. The CEO of the Group is Bernd Reifenhäuser.

About R-Cycle

R-Cycle is a cross-company initiative to develop an open and globally applicable tracing standard for sustainable plastic packaging. The aim is to automatically record recycling-relevant packaging properties during production by providing a digital product passport and to pass them on through the value chain. Recyclable packaging can then be identified in the recycling process via special markings and fed into pure waste fractions. This is the key to obtaining high-quality recyclates to close the loop. www.r-cycle.org