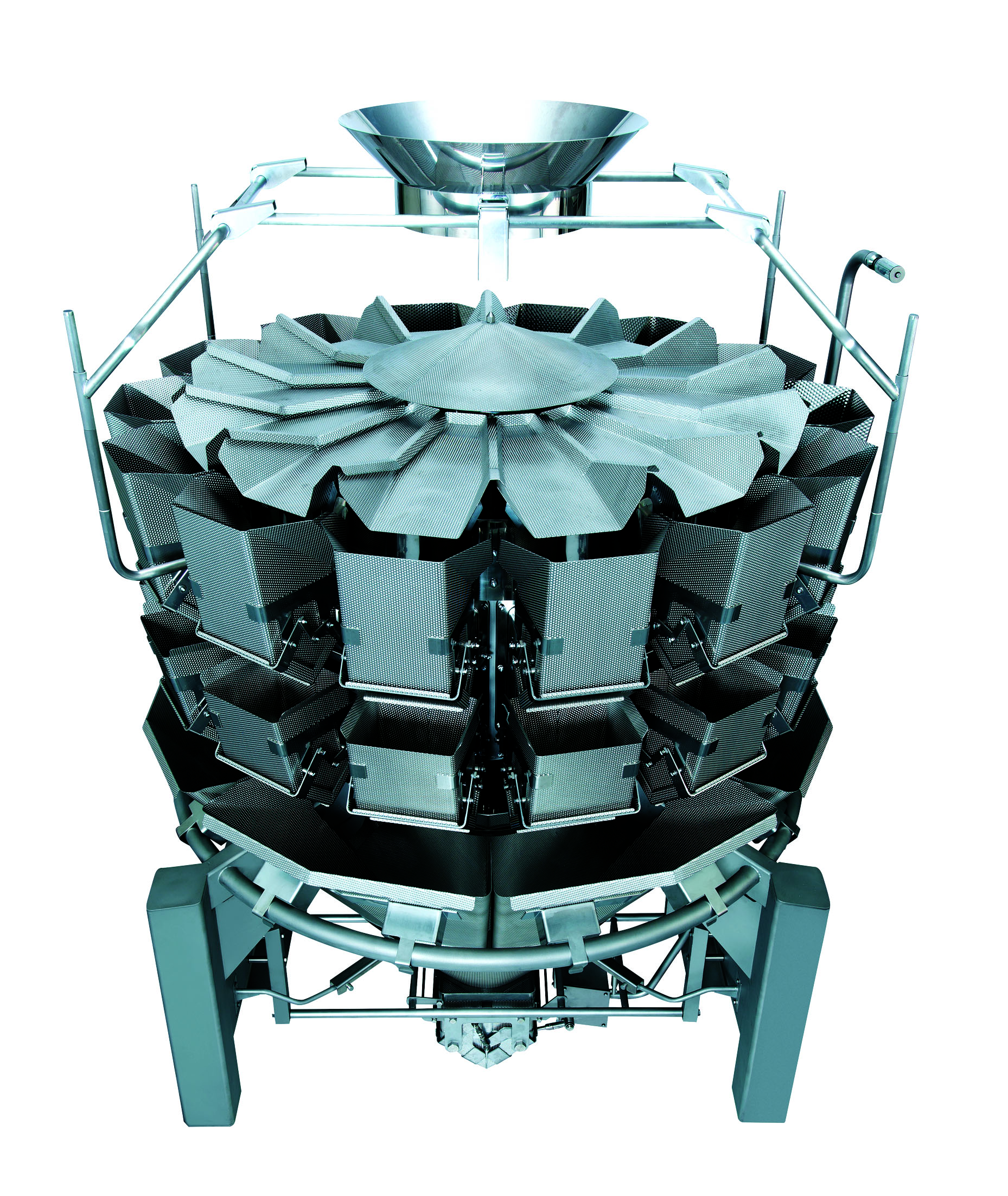

Ishida has expanded its high-performance hygienic multihead weighers for fresh and frozen applications with the introduction of a range of models with a new open frame design that allows fast and easy access for cleaning and inspections, particularly in the timing hopper area.

The new design for the Ishida CCW-RV 10 and 14 head WP waterproof models means there is no conventional base unit to restrict access to the lower contact parts. In addition, the design allows the weigher to be positioned lower in the separating floor of a factory. The frame itself can also be integrated into a concrete floor and sealed, preventing excessive wash down water drain onto equipment installed below the weigher.

Other features include a sloped dispersion feeder cover and frame, which are self-draining and free of crevices, exposed screw threads, and other areas where bacteria and debris might accumulate. The power control unit is securely isolated in a separate waterproof cabinet, which can be mounted on the weigher frame or remotely located up to 20m away. This effective protection of the sensitive electronics means all product bearing surfaces can be thoroughly and regularly cleaned without the need to protect water- and temperature-sensitive parts in that process.

The new weighers are available with product hoppers in 3, 5 and 7 litre capacities, making them ideal for a wide range of fresh and frozen meat, poultry, seafood, vegetables, fresh fruit or salad applications. Rapid hopper opening and closing cycles deliver weighing speeds of up to 180 per minute depending on the application. …/

In addition all models are pre-configured for the new generation of ‘smart’ factories and are available with a choice of packages incorporating Ishida’s pioneering Sentinel™ remote customer care software. This provides users with the options of automated daily reporting of production line data, remote interventions or a live performance monitoring service.