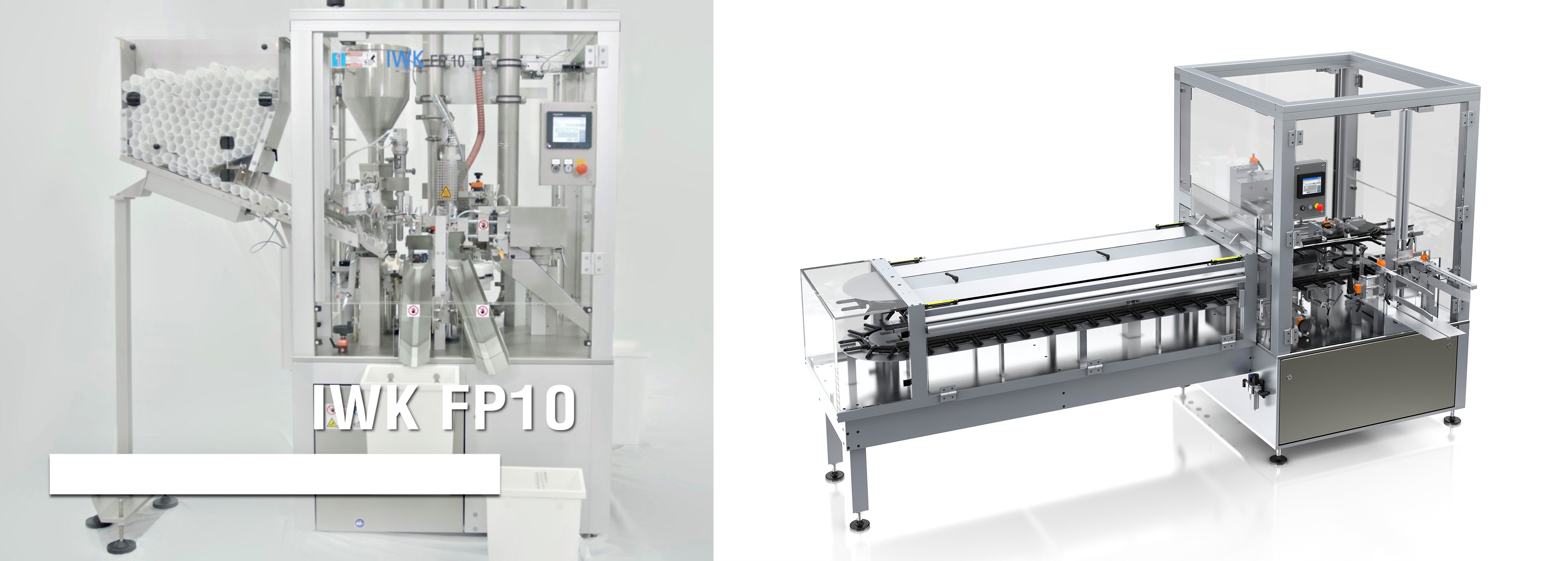

Affordable VI 5 Vertical Cartoner can be upgraded for feeding by the FP 10 Tube Filler, offering an effective product flow and cost-effective solution in a minimal footprint.

Parsippany, NJ – IWK, a manufacturer of premium tube filling and cartoning equipment for the pharmaceuticals and health & beauty sectors, will showcase machinery addressing two of its niches – tube filling & cartoning together to form an integrated line – at Pack Expo Las Vegas Booth C-5428, September 11-13.

The low-cost FP 10 Tube Filler features an innovative hot air tube heating system for sustainability-minded energy savings. Its sound mechanical design allows excellent accessibility from all sides, without the type of blockage sometimes caused by electrical cabinets. Maximum process reliability is assured via servo technology, and changeovers can be performed in under 15 minutes. For manufacturers running other IWK tube filling equipment, the FP 10’s format and product contact parts are interchangeable throughout the entire FP Series. Capable of filling and closing up to 70 tubes per minute, the FP 10 can handle metal, plastic or laminated tubes.

IWK’s FP 10 Tube Filler is operated via a 5.7“ HMI Touch Panel offering an intuitive, ergonomic user interface. Relevant process parameters¬ are vividly displayed, and changeover directives are concise. A running count of both good and potentially faulty tubes is showcased throughout the duration of product runs. Remote servicing is available via wifi.

The VI 5 Vertical Cartoner is an intermittent motion machine with an open, accessible work area and a modularly extendable length that optimizes floorspace. Suitable for a wide array of components including bottles, tubes, blister packs, jars, pouches and other similar components, the touchscreen-operated VI 5 can produce up to 75 cartons per minute.

Among the VI 5's key highlights is the ability to change formats quickly. This functional versatility is aided by easy, repeatable changeover steps, a centralized transport height adjustment system, and carton buckets exchangeable through a click system. No adjustment of rails is needed along curves, further expediting product changeovers.

The VI 5's servo-driven, cam-guided transport system offers premium positioning precision. The basic machine comprises 22 carton carriers and a corresponding number of stations; optional transport system extensions can bring the total stations up to 40, or even 54. Other options, including leaflet feeders, booklet feeders and automatic product loading, also are available.

“Regardless of the packaging platforms, our machines strive for exceptionally high levels of functionality at a surprisingly cost-effective price point,” said Dana Austin, General Manager North America. “This FP 10 + VI 5 tube filling cartoning line is most ideal for lower volume needs, enhanced productivity, or maximizing efficiencies, all with reduced manpower needs.”

About IWK

For over 130 years, IWK has designed and engineered cutting-edge tube filling and cartoning machines for a wide variety of industries, predominantly the pharma and health & beauty sectors. Leaning on modern technology while standing on the shoulders of prior successes, the company’s equipment is known for offering outstanding performance and unsurpassed reliability.

IWK’s main objective is to keep its customers’ operations running with maximum productivity. To help ensure this, more than 15% of the company’s workforce is dedicated to pre-sales engineering concepts and aftersales service. IWK currently supports more than 10,000 packaging systems around the world with rapid response times and 24/7 service availability. For more information, visit www.iwk.de/en.