New MMS 2 is half the size of its predecessor, and its modular design enhances versatility; WIPOTEC also will showcase HC-A-V Checkweigher, combining precision checkweighing with dual camera inspection.

Roswell, GA – WIPOTEC Weighing Technology, a division that manufactures weigh cells utilizing (EMFR) electro-magnetic force technology for use in checkweighing, filling/dosing and packaging lines, will introduce the next generation of its Modular Multilane System at PACK EXPO Las Vegas, Booth #SL-6106, September 27-29, 2021. The new MMS 2 is 50% smaller than the previous model, and features a modular, plug in-and-out design that significantly enhances the unit’s flexibility.

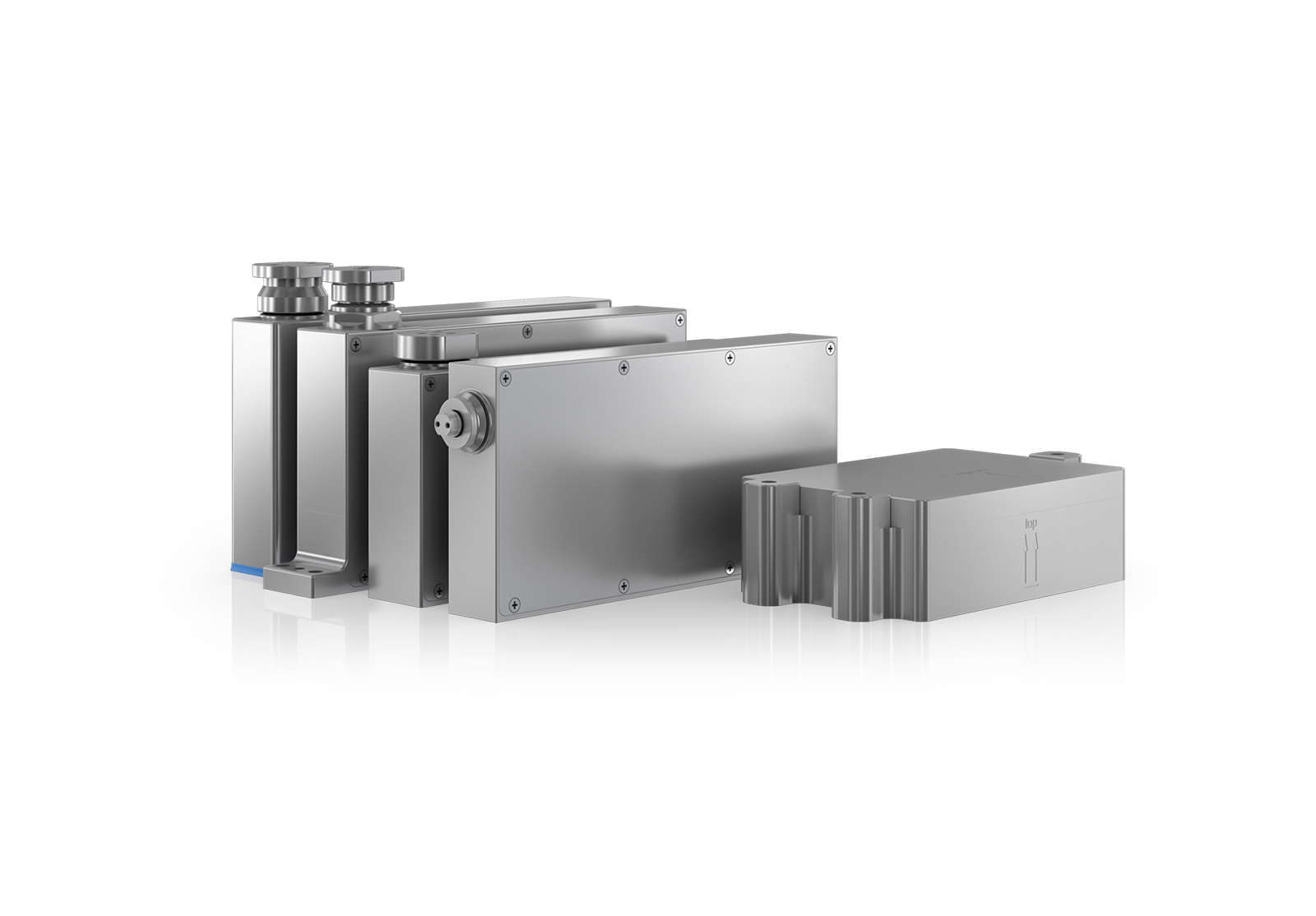

The MMS 2 is an ideal weigh cell for production lines in a variety of settings, including quality control scenarios for vial and syringe filling and other scenarios necessitating customized inspection. Its space-saving design allows lane modules to be arranged side by side, and eliminates the need for an additional cabinet – a key benefit for machine manufacturers. The MMS 2 offers IP65 protection for safeguarding components against dust, foreign materials, water and other environmental factors.

All weigh cells of types SL-M-FS, SW-M-FS and SX-M-FS series can be used with the MMS 2. Like all WIPOTEC weigh cells, the MMS 2 utilizes high-tech Electro-Magnetic Force Restoration (EMFR) technology, a differentiating engineering design that guarantees precise weighing results. In addition, the MMS 2 can be combined with the company’s Active Vibration Compensation (AVC) technology in situations where weighing results and cycle rates may be adversely affected by surrounding vibrations or interference.

Also at Pack Expo, WIPOTEC-OCS will showcase its recently introduced HC-A-V Checkweigher, a quality control solution combining sophisticated checkweighing technology with premium visual inspection. Providing two critical functions in one compact frame, the unit is applicable for a broad array of consumer packaged goods, including food & beverage items.

The new quality assurance system adds high-resolution camera inspection to exceptionally exacting HC-A Checkweigher, building upon its precision checkweighing with a company-developed vision control system that checks items from both above and below. The result is a bevy of additional benefits, including cover film verification, sell-by date confirmation and 1D/2D barcode examination. Images of any rejected items are archived for reporting and troubleshooting.

The HC-A-V Checkweigher can handle up to 200 items per minute, and is as versatile as it is exacting: WIPOTEC-OCS can customize the machine’s various configurations – including weigh cell type, conveyor types/lengths/widths, product eject mechanism, and product handling – to meet unique customer and product requirements. For seamless product transport, the HC-A-V Checkweigher utilizes NT30 conveyor belts with knife edge and comfortable belt width. WIPOTEC-OCS servomotors ensure consistent speed, and digital light curtains provide reliable product identification.

About WIPOTEC-OCS, Inc.

WIPOTEC-OCS, Inc. is a leading manufacturer and supplier of precision in-motion product weighing, X-Ray scanning, product inspection, parcel dimensioning, package marking, and serialization and aggregation equipment. The company's weighing, inspection, and track and trace solutions serve applications in a broad array of industries, including pharmaceutical, food, chemical, cosmetics, healthcare, e-commerce and logistics.

Located in the Atlanta, GA suburb of Lawrenceville, WIPOTEC-OCS headquarters includes a demonstration showroom, customer application engineering labs, a spare parts warehouse, and state-of-the-art meeting and training rooms. The company is part of Germany-based WIPOTEC group, which employs more than 1,000 people worldwide and has been pioneering dynamic weighing solutions for more than three decades.