A new formula for Emballage, the international packaging exhibition scheduled in Paris from 14 to 17 November. For Sacmi, it is an opportunity to present the latest evolutions in its range to the European market, with increased focus on greater process efficiency and service excellence.

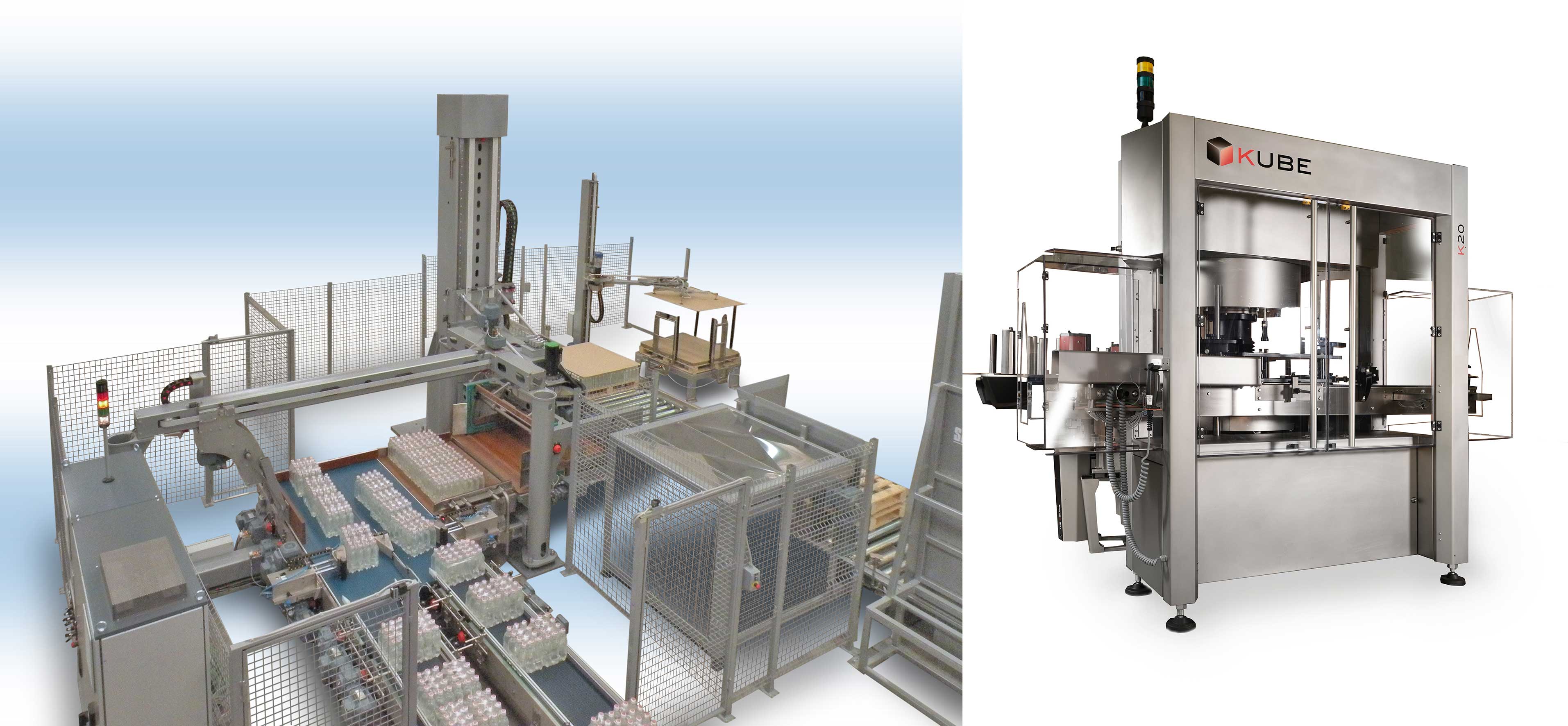

Capsules and containers that are even lighter and perform better; integrated technologies to pass from a pellet to a container in just one step; and automated systems for label application and quality control, and for the forming of primary packaging: these are the distinctive features of the Sacmi beverage packaging solutions, which are key attractions at the 41st Edition of Emballage, the international packaging exhibition scheduled in Paris from 14 to 17 November 2016.

A European benchmark for industry producers and buyers (the 2012 Edition concluded with a grand total of almost 1,300 exhibitors and 90,000 visitors), Emballage 2016 will be presented to the market with a new formula, "All4pack Paris", in synergy with the Manutention trade fair, in order to cover all packaging, process and printing system solutions, together with solutions for intralogistics. Sacmi will be participating in the exhibition with an official stand (hall 6 no. 6F021). Here visitors can gain firsthand knowledge of the evolution of the Group's product range towards "packaging 4.0", integrated solutions that combine technological excellence in individual machines with production process management solutions.

One example is the Sacmi CPB Link, a highly automated dynamic buffer. "It is the first automated warehouse for capsules and preforms,” emphasises Iacopo Bianconcini, Marketing Manager of the Group's Beverage and Closures and Containers Division, “and provides a connecting link between production solutions for capsules and preforms and integrated blowing-filling lines. The result is the first truly complete line for the beverage world, equipped to meet the natural needs for flexibility on bottling lines, such as frequent downtime for format changes and different seasonal production patterns."

This process efficiency is combined, at Sacmi, with technologies and innovations that cover the entire plant design chain. These include solutions for the production of containers and capsules using compression technology, with which Sacmi has set the standard worldwide in terms of productivity, quality and energy efficiency. There are also modular labelling machines designed to combine high productivity with ease of use and total assurance regarding label quality, thanks to the integration of vision and quality control systems throughout the range.

A global player and plant supplier for the industry, for years Sacmi has united its products and services in the beverage packaging sector under a single production and marketing logic: "ever greater attention to the market,” notes the Marketing Manager of the Group's Beverage and Closures & Containers Division, “not only as a supplier of technology, but also and above all as a service company". This is borne out by constant investments in the creation of new subsidiaries and after- sales service centres in five continents, to provide customers throughout the world with an efficient parts service and prompt technical assistance. The activities of the Group's Beverage R&D Laboratory support the customer right from the design phase and are certified by major international players in the industry, as a reference point for the development and testing of solutions that can then be industrialised and placed on the market.