With 45 years of experience in hot filling and over 1,000 pieces of equipment for hot fill packaging installed worldwide, Sidel is highlighting how beverage producers can safely handle sensitive and natural beverages such as juices, teas and sports drinks. Sidel ensures beverage safety with tailored PET packaging solutions to provide a complete top quality, cost-efficient and sustainable production.

The annual market growth of 6% 1 for the consumption of sensitive drinks such as juices, nectars, still drinks, isotonics and teas presents significant business development opportunities for beverage producers worldwide. The popularity of packaging solutions using PET Hot Fill technology continues to rise in this field. Sidel leads this development with a complete Hot Fill solution that expands packaging opportunities. The company’s packaging engineers and designers are dedicated to developing attractive and sustainable PET bottles to differentiate beverages on the supermarket shelf. Using the most advanced technical and fully integrated solutions, Sidel is able to ensure detailed control and transparency throughout the whole process. Complemented by ongoing tailored services, producers are able to meet changing consumer needs and market requirements.

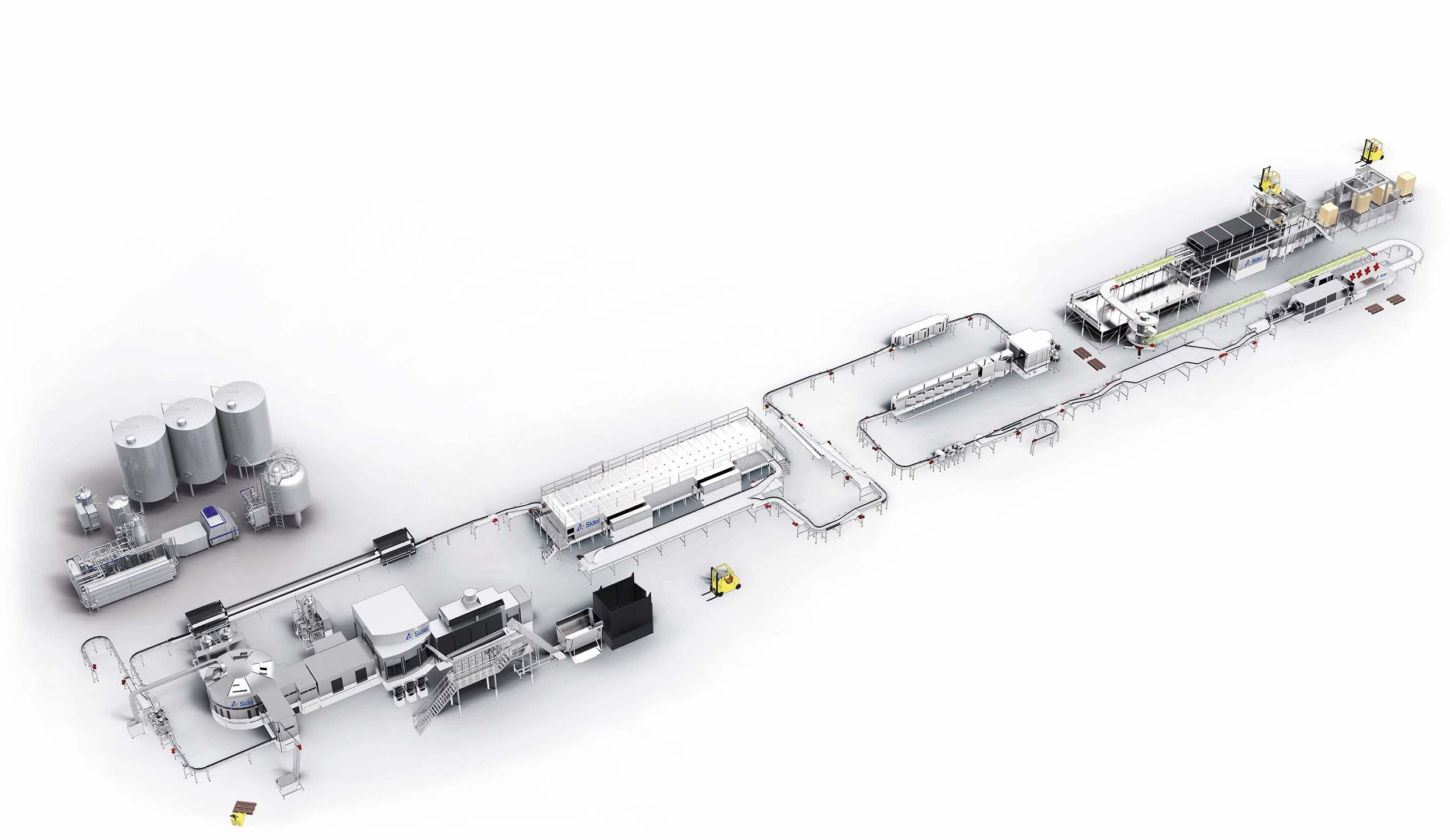

Integrated efficient production for hot filled beverages

Fully integrated and flexible, Sidel PET Hot Fill packaging solutions provide reliable and safe production. By taking a holistic view of the production cycle and line performance, Sidel optimises uptime and operating costs. Focusing on the specific features of the customer’s packaged beverage, Sidel’s solutions employ the processing equipment and capabilities from Tetra Pak Processing Systems, to ensure processing and filling systems are seamlessly combined to reduce downtime, consumption and costs. Based on control and regulation systems, producers can increase performance and make more informed decisions, ensuring optimum hygiene, efficiency and safety throughout the supply chain.

Pioneer in top quality PET HR bottles

Gabriele Gatti, Sidel Filling Product Manager, comments – “Today, juices, still drinks and teas constitute the fastest growing segment of the beverage industry. PET packaging - already the material of choice for 40% 2 of these beverage types and still growing in popularity - is an attractive and sustainable way for sensitive beverages distributed at ambient temperature.” Combined with aseptic or hot filling production, PET can ensure beverage products’ safety across their shelf life. In terms of Hot Fill, the temperature of the beverage heating process is as high as 80-92°C which is above the normal thermal resistance of conventional PET bottles. “This requires specific packaging and equipment to allow PET to resist to hot filling temperature. In 1986, Sidel pioneered the heat-resistant (HR) stretch blow moulding process to allow PET bottles to withstand these high temperatures, since when the company has driven PET’s transformation into the flexible packaging solution it is today.”

Enhanced design freedom for lightweighted HR PET bottle

Sidel’s global packaging capabilities, including PET bottle design, combined with its expertise in hot fill production, provide the means to produce bottles that are both resistant and attractive. Today, from designing the preform all the way to the blowing process, the company undertakes a singular approach to achieve HR PET bottles of the highest quality. Sidel has significantly reduced the weight of HR bottles while retaining their durability and increasing the bottle design opportunities. This latter achievement is due to the elimination of vacuum panels - previously a design necessity to absorb the variations in volume that the HR bottle and contents undergo passing from hot to cold conditions, and also to the innovative and efficient electrical mould heating and accurate material distribution. As a result, the distinctive bottle shapes stand out on the supermarket shelves - and consistently deliver a great consumer experience.

Responsive mould heating combined with accurate blowing

Sidel’s latest model for HR bottle production - the Sidel Matrix™ eHR blower - adds yet another innovative dimension to the company’s hot fill solutions. Traditionally, PET bottles for hot filling are produced via the heat-resistant stretch blow moulding process at 120°/140°C - a temperature usually attained by circuits of hot oil. By using electricity instead to heat the mould for the PET bottle body, the Sidel Matrix eHR blower enhances operator safety preventing hazards caused by oil leakages, such as operators' slipping and product contamination. Probes are directly located in each mould shell to regulate the temperature as closely as possible to the PET bottle as it is formed. The process is very responsive, heating at a rate three times quicker than by oil, accurately providing the correct temperatures immediately from the very first bottles produced. This results in a blowing process which is uniform between blowing stations, ensuring high bottle quality and consistent performance in the hands of the consumer, even at outputs of up to 2,000 bottles per hour per mould.

Compared with Sidel blowers that used traditional heating with oil, this innovative electrical mould heating and the proven Sidel Matrix blower technologies offer together energy savings of up to 45%. A further saving of 25% can be achieved with Sidel Matrix Ecoven, which uses infrared lamps with ceramic instead of metal reflectors. A reduction by up to 45% of air consumption is possible by implementing Sidel’s air recovery option, AirEco2.

Highest standards of hygiene and operational reliability

To meet the production demands of sensitive and natural beverages, the Sidel Matrix™ hot filler – SF700 FM offers the highest standards of hygiene and operational reliability during filling. It can be used for a variety of sensitive beverages, with or without pulps. Beverages containing particles up to 10 x 10 x 10mm can also be handled with a double stage filling. It is suitable for PET bottle sizes ranging from 200ml to 3 litres. Operating at production rates ranging from 6,000 to 60,000 bph, it features electronic filling valvesequipped with individual flow meters that ensure precise filling volumes while minimising product wastage. Its operation of contactless filling - where there is no contact between the filling valve and the bottle neck - optimises product safety throughout the whole process. Additionally, by integrating the very best of the electrical HR blowing and hot filling technologies in one single controlled production environment, the Sidel Matrix Combi Hot Fill eliminates conveying and allows hygiene and food safety to be maintained.

Safe, effective and sustainable process environment

Once the beverage is filled and the bottle capped, beverage safety and consistency are ensured by sterilising the head-space and cap with the Sidel cap steriliser. It controls this process by tilting the bottle at a precise angle, temperature and contact time. This step puts all internal surfaces and air space in contact with the hot beverage, eliminating microorganisms and extending product shelf life. Sidel’s cooling system cools the product while avoiding thermal stress and preserving organoleptic properties, taste and colour, for a great consumer experience. The modular cooling configuration can be easily upgraded to match the production needs of today and tomorrow. Additionally, the advanced engineering allows a precise sizing of the cooler with a 20% reduced footprint and minimal water consumption compared with traditional solutions. Line integration with Tetra Pak Processing Systems can also lead to energy savings of up to 45% by recovering, for example, warm water from the cooler for pre-heating at the pasteuriser.

Optimising uptime and operating costs

Taking this holistic view of the production cycle and line performance, Sidel helps producers optimise operating costs and reach the lowest total cost of ownership (TCO). Sidel Services™ offers a tailored portfolio of maintenance, line improvement, training, spare parts and logistics, line conversion and moulds and packaging services to help maintain, regain and even improve performance throughout the line’s lifetime. In this way, by partnering with the company producers get the benefit of having everything centred around a single, reliable global supplier. Gabriele Gatti comments: “Once the productivity and performance targets of a line are reached, we believe that the minimum goal should be to maintain and even improve these levels over the coming years. As new technologies and solutions are developed, Sidel offers existing line owners options and upgrades to ensure that existing equipment does not get left behind.” Having staff trained on new procedures and emerging methodologies to enhance their performance can also improve production by turning costly downtime into profitable uptime.