The oil and gas market can change at any moment. Unfortunately, infrastructure development takes so long that a good market outlook at the beginning of a greenfield projec t may have completely changed by the time offshore installation is done. It is therefore important for oil and gas companies to have adaptable, low maintenance corrosion solutions to preserve topside and subsea piping and pipelines in case of delayed commissioning from unexpected market drops.

Topside and Subsea Preservation Needs

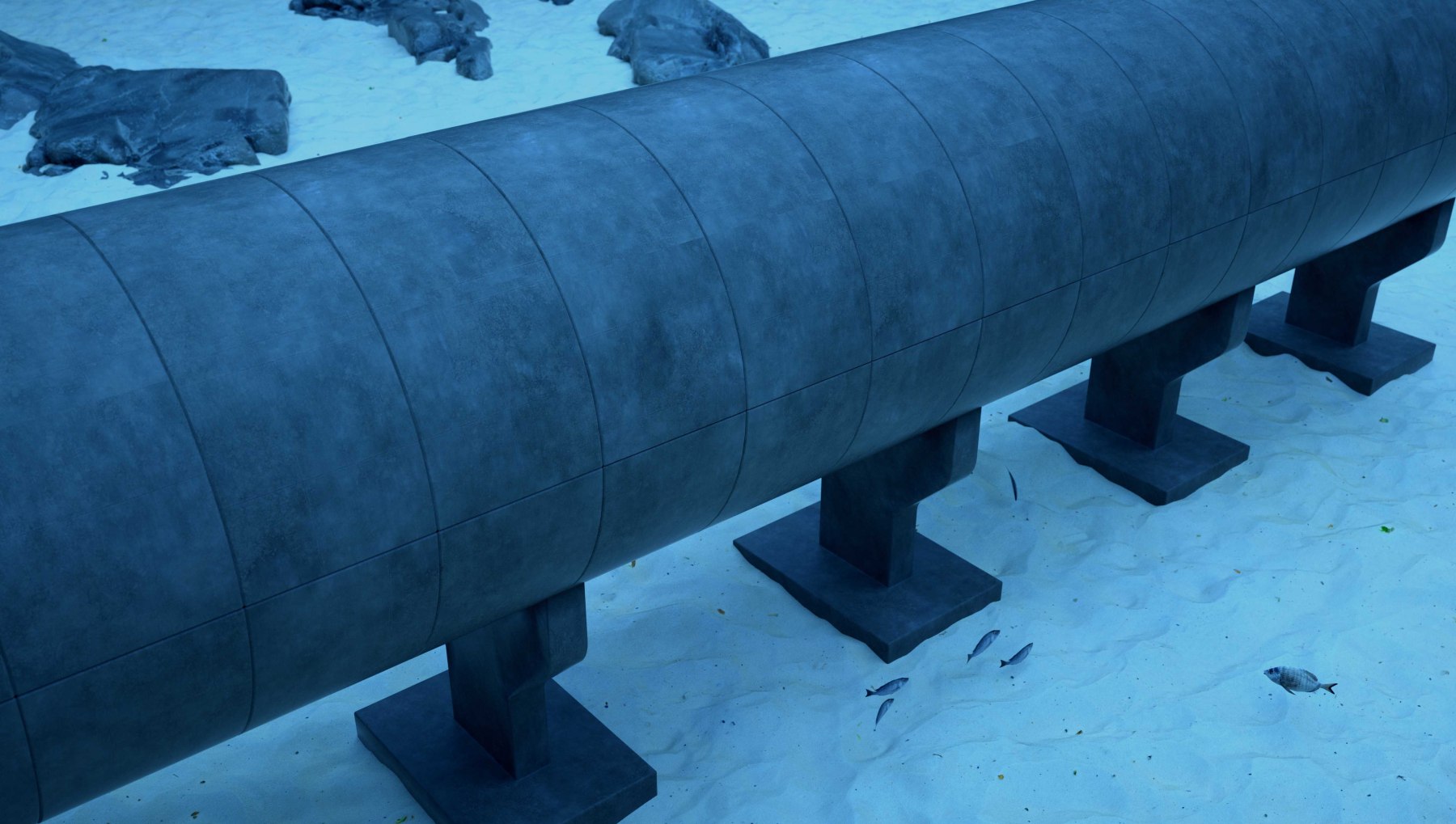

Internal corrosion threatens the longevity and integrity of piping and pipelines, which are indispensable to offshore production. On the topside are water injection systems, gas piping systems, and crude oil lines that need protection. Subsea gas lift lines and pipelines carrying crude oil from platform to platform or from platform to land also need to be preserved. Even when other systems are commissioned, water injection and gas lift lines may need extended preservation until a drop in well pressure demands their use.

The Practical Beauty of Vapor phase Corrosion Inhibitors

Vapor phase Corrosion Inhibitors increase the ease and flexibility of preserving tubular voids. The beauty of these inhibitors is that they vaporize and disperse themselves throughout an enclosure, adsorbing on metal surfaces to create a self-replenishing protective molecular layer. As long as the space stays closed, there is no need to maintain constant pressure or continue frequent monitoring as for nitrogen blanketing. Vapor phase Corrosion Inhibitors can be added to fluids or oils or simply fogged as a vapor into enclosures. Typically, little to no removal and/or cleaning is required before commissioning.

Multiple Scenarios for Offshore Protection

There are many ways to apply Vapor phase Corrosion Inhibitors to offshore piping and pipeline systems. A creative option for short-term protection of subsea pipelines is to place Cortec® EcoPouches—breathable bags containing Vapor phase Corrosion Inhibitors—into a plenum and to blow the vapors through the system until they are detected at the other end. The system should then be closed to trap the vapors inside.

Another option is to apply Cortec® VpCI®-649 BD, a water-based liquid concentrate that can be flushed through the system to provide up to two years of preservation, depending on dosage. As VpCI®-649 BD circulates, it forms a thin protective film on the walls of the piping. This film inhibits corrosion on the metal it is directly touching but also emits vapors to protect surfaces in harder to reach areas that may have been missed during application.

A final example is long-term preservation of subsea pipelines. This task is often performed by using nitrogen to purge all oxygen out of the system. Constant pressure must be maintained to ensure effectiveness. Since it is difficult and costly to monitor this on unmanned offshore platforms, it is better to have a complete replacement for nitrogen or a backup system that will continue to work even if nitrogen pressure fails. A good answer is to fog an oil-soluble Vapor phase Corrosion Inhibitor through the subsea pipelines, either alone or in conjunction with nitrogen. Once the corrosion inhibitors are detected at the other end of the pipeline, the openings can be closed and (if nitrogen is used) the system pressurized. In the event of lost pressure and nitrogen, protection will continue thanks to Vapor phase Corrosion Inhibitors.

Stay Adaptable to Changing Market Demands

Whatever the market holds, it is important to have effective and efficient preservation methods that make it easier for oil and gas companies to respond to market demands. Vapor phase Corrosion Inhibitors meet this definition and can help greenfield project owners stay adaptable in uncertain times. Contact Cortec® to learn more about the many ways this technology can be used to preserve topside piping and subsea pipelines when offshore commissioning is delayed.