Society ROSAS, specialized in renovation of packaging machines, has developed a process to obtain packages with 100% oxygen free on thermoformer machinery. This process was built on two complementary patents.

The first patent allow them to inject fluids directly inside the middle of the sealing enclosure Instead of perforating the usual holes on both sides of the plastic film. As a result, this process reduces the width of the plastic film, both on the upper and the lower rolls, and save up to 15% of film ! (More technical details on WIPO web site.) See our schematic Patent 1.

The suppression of the perforating tools has another hygienic effect. On regular thermoformer machines, these tools cannot be totally cleansed, and since they usually made of steel they contribute to "pollute" the atmosphere inside the sealing enclosure.

Rosas patent 1 This device is already in use and can be adapted on any kind of thermoformer machinery, Among their customers using their machines and saving 15 % of plastic film.

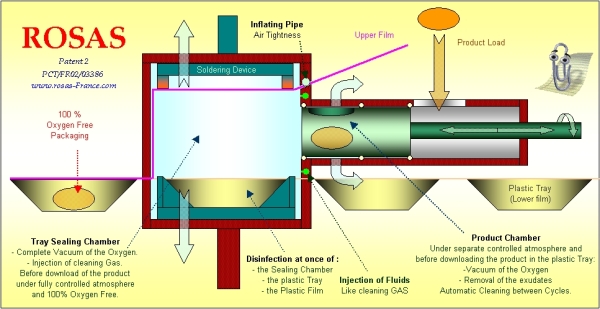

As a extension of the first patent, the second one goes further allowing this time to introduce directly the product, solid or liquid, inside the tray sealing enclosure, under a perfect controlled atmosphere.

With a double chamber system, it is now possible to vacuum the 'tray sealing enclosure' in order to obtain 100 % of Oxygen free before introducing the product. Depending on the product, this result can even be guaranty going through 3 stages (most of the time the first one being enough): bio chicken

Vacuum of the enclosure removing most of the oxygen.

Injection gas like CO2. (This Gas absorbs automatically the oxygen molecules left behind)

Second vacuum of the 'Loaded' CO2

At the same time, on a separate 'controlled atmosphere' chamber, the product is also vacuumed to remove the oxygen, but also exudates, and then introduced in the plastic tray completely free of oxygen.

It is well known that removing 100 % of oxygen from the food can extend shelf life of fresh foods. (Canadian labouratory Alimentech) The difficulty being usually to succeed in obtaining a perfect vacuum while the product is already inside the tray, and then holding oxygen. (Animation) See our schematic Patent 2.

With theses patents, the length of the shelf date depends now on the quality on the plastic film once thermoformed. With a good plastic film, it could be extended from 21 days to more than 21 weeks. Some plastics makers in US are already working on this issue.

Let's imagine that the actual plastic film can last only 8 or 10 weeks, (Keeping fresh products between -1 and + 3 ' Celsius). No more required freezer for transportation (Ship, lorry'), just cold rooms keeping a much better quality of the product for a long period of time. This is also changing completely the cost of long distance transportation and without all the troubles of defrosted food.

For industrials this process has also other big advantages like the suppression of clean room since the product is directly carried inside the plastic tray. For the same raison this process is also removing the laminar flow effect in case of liquid products.

This patent is a real 'revolution' changing completely our way of Packaging, Storing and Transporting Food and Products in the world. Rosas has developed a prototype proving the efficiency of this second patent, and is still looking for partners to use those two innovations.