In today’s rapidly evolving packaging industry, where efficiency and precision are crucial, staying ahead requires innovative solutions. Companies are under constant pressure to meet growing demands while upholding the highest quality standards. This is where PakTech steps in with its latest breakthrough—the TwinKlip Applicator (TKA). This cutting-edge machine is set to transform the application of TwinKlip handles, offering an unparalleled combination of speed, versatility, and safety. For businesses still manually applying TwinKlip handles, the TKA is poised to be a game-changer, delivering substantial ROI and operational enhancements.

The Innovation Journey

At PakTech, innovation is born from a deep understanding of customer needs. The TwinKlip Applicator's development began with a keen observation: many businesses were investing excessive time and labour in manually applying TwinKlip handles. Recognizing this inefficiency, PakTech seized the opportunity to create a solution that would not only streamline this process but also significantly boost productivity. The TKA is the result of our unwavering commitment to listening to our customers and providing state-of-the-art solutions to their most pressing challenges.

Key Features of the TwinKlip Applicator

The TwinKlip Applicator is designed to maximize efficiency and user-friendliness. Here are its standout features:

-

High-Speed Application: The TKA can apply TwinKlip handles to products at an impressive rate of 120 bottles per minute, ensuring that businesses can keep up with high demand without compromising efficiency.

-

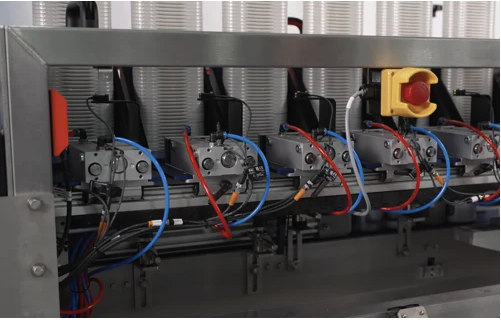

Pneumatic Gates for Precision: Equipped with pneumatic gates, the TKA ensures precise bottle control during the shucking and application process. This feature guarantees accurate handle application, reducing waste and enhancing product quality.

-

User-Friendly Interface: The TKA features an Allen Bradley touchscreen HMI (Human Machine Interface) for intuitive operation. The tilt and swivel pendant allows for control from either side, offering both flexibility and convenience.

-

Safety at the Forefront: Safety is a top priority with the TKA. The machine is equipped with easy-access guard panels and safety interlocks for hassle-free adjustment and cleaning, along with a Category III safety system to ensure the highest levels of operational safety.

-

Adaptability: One of the TKA’s most notable features is its ability to handle various products on the same base machine. Its fully adjustable design allows businesses to switch between products with minimal downtime, thereby enhancing versatility and productivity.

-

Efficient Loading and Operation: The TKA’s lightweight handle loading tools serve as magazines, extending runtime between reloads. An LED lightbar provides instant machine status updates, enabling operators to monitor and manage the process efficiently.

-

Quick Changeovers: Designed for quick adjustment of magazine positions during product changeovers, the TKA minimizes disruption and maximizes uptime.

The ROI of Implementing the TwinKlip Applicator

For businesses currently applying TwinKlip handles manually, the TwinKlip Applicator represents a significant return on investment. Here’s how the TKA can revolutionize operations and enhance profitability:

-

Labor Savings: Manual handle application is labor-intensive and time-consuming. By automating this process with the TKA, businesses can reallocate labor to other essential areas, reducing costs and boosting overall efficiency.

-

Increased Throughput: With the TKA’s capability to apply handles at 120 bottles per minute, businesses can process more products in less time, meeting higher demand and driving revenue growth.

-

Reduced Waste and Enhanced Quality: The TKA’s precision ensures correct handle application every time, reducing waste and improving the quality of the finished product. This not only cuts costs but also enhances customer satisfaction and brand reputation.

-

Flexibility and Scalability: The TKA’s adjustable design allows businesses to handle multiple products on the same machine. As product lines expand, the TKA scales with operations, providing long-term value and adaptability.

-

Improved Safety: The TKA’s robust safety features minimize the risk of accidents, ensuring a safer work environment. This can lead to lower insurance costs and fewer operational disruptions.

PakTech’s TwinKlip Applicator stands as a testament to how innovation can drive efficiency, quality, and profitability in the packaging industry. For companies looking to stay ahead in a competitive market, the TKA offers a powerful solution that combines speed, precision, and safety in one sophisticated package.