At a Glance

- Costco’s new package incorporates recycled content and is fully recyclable

- There was a polymer change for the custom-engineered track-and-slider closure

- Plastic tub-to-pouch switch reduces plastic use by 1.2 million lb yearly

A trio of collaborative plastic packaging suppliers has been honored with a World Packaging Organisation 2024 WorldStar Award for developing a child-safe, fully recyclable pouch for water-soluble laundry detergent packets called “pacs”. The package, created for a Costco store brand, won in the WorldStar household category.

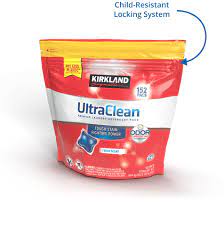

Accredo Packaging, Fresh-Lock closures/Presto Products, and Radienz Living collaborated on the reclosable Kirkland Signature Ultra Clean HE Laundry Detergent Pacs pouch, which replaces a 152-count rigid plastic tub.

Accredo is film supplier, printer, and packaging manufacturer; Fresh-Lock supplies the pouch’s reclosable, child-resistant track-and-slider closure; and Radienz Living provides contract manufacturing.

The goal of the packaging redesign was to create a more sustainable and cost-effective pouch without sacrificing safety or packaging performance. The new package also needed to provide shelf impact and accommodate the same number of pacs per pouch and packages per pallet.

Closure change assures pouch recyclability.

“For the success of this pouch, every aspect needed to be rethought, not only for how it worked but for how it would be compatible with the other parts,” says Sarah Stieby, Fresh-Lock marketing manager.

The packaging material is Accredo Packaging’s AccredoFlex Gen2 film structure. “The film requires less energy to produce, offers improved temperature resistance, and has excellent contact clarity,” Stieby says.

This polyethylene (PE) film also contains recycled plastic. The film “currently uses a minimum of 25% post-consumer recycled content but … the team is collaborating to increase this percentage while continuing to deliver on the performance and consumer expectations of the original pouch,” she notes.

For the closure, Fresh-Lock engineered its Child-Guard track-and-slider technology to be made from PE while matching the run rates and performance of the original polypropylene version. The pouch’s slider was designed to endure a pac-count-matching 152 open-close cycles without sacrificing child-resistance.

The PE closure enables the entire pouch to qualify for the How2Recycle in-store drop off program; the How2Recycle store drop-off logo is printed on the back of the pouch to guide consumers on disposal.

To assure operational efficiency, Radienz sourced a filler that can handle this first-of-its-kind pouch size for water-soluble laundry pacs.

Going forward, the pouch offers a child-safe, sustainable option for other products such as pharmaceuticals and household cleaners.

Pouch's sustainability and retail benefits.

Compared with the tub used previously for the laundry pacs, the pouch uses 80% less plastic and has an 85% smaller carbon footprint.

Switching to the pouch has generated diesel fuel savings of more than 600,000 gallons annually and a reduction in transportation-related emissions equal to 6,131 tonnes/6,758 tons of carbon dioxide equivalent.

Costco also cut annual resin use by about 1.2 million lb yearly, based on switching 220,000 packages per month from tubs to pouches.

In addition to its sustainability features, the pouch is visually appealing. The film structure provides “high-quality print capability for outstanding graphic appeal,” Stieby says, noting that Accredo’s “innovative ink delivery system eliminates all ink changes, resulting in up to 95% less ink waste and significant reduction in solvent usage. This waste reduction helped enable a more sustainable pouch solution that looks great on the shelf.”

The pouch’s “overall performance and appearance, combined with excellent toughness and durability, make this a standout package for Kirkland Signature laundry pac consumers,” she adds. “Costco has claimed consumers prefer the new packaging solution, and sales have exceeded expectations.”