Wooden pallets are often used for transporting goods. But some alternatives could have critical advantages. For example, the manufacturer of plastic pallets Cabka produces pallets made of recycled plastics which are especially suited for the chemical industry.

The new generation of Eco CP3 and CP9 pallets are sustainable load carriers specially suited to the needs of the chemical industry. They offer several advantages for companies. The plastic pallets do not warp and have a long service life, as they are unaffected by shrinkage and breaks. In automated storage and transport systems, the pallets ensure a high level of process reliability and an exact fit, as their dimensions and shapes do not vary.

Employees benefit from the low weight of the pallets, which reduce their workload during manual handling. The low weight also contributes to the sustainability of plastic pallets – during transport, both costs and carbon emissions are saved. The surface of the pallets is robust and free of toxic substances, and therefore easy to clean, which makes it possible to comply with the hygiene standards of multiple different areas.

FACTS AND FIGURES

On the business side, especially when it comes to logistics, plastic pallets can reduce the amount of needed space and thus storage costs. The portfolio of Cabka includes the Eco CP3 and Eco CP9 plastic pallets. The three-runner pallet CP3 is suitable for dynamic loading up to 1,400 kg. It is made of recycled polyolefins with dimensions of 1,140 x 1,140 mm and a height of 150 mm. The weight of the pallet is approx. 12.5 kilograms.

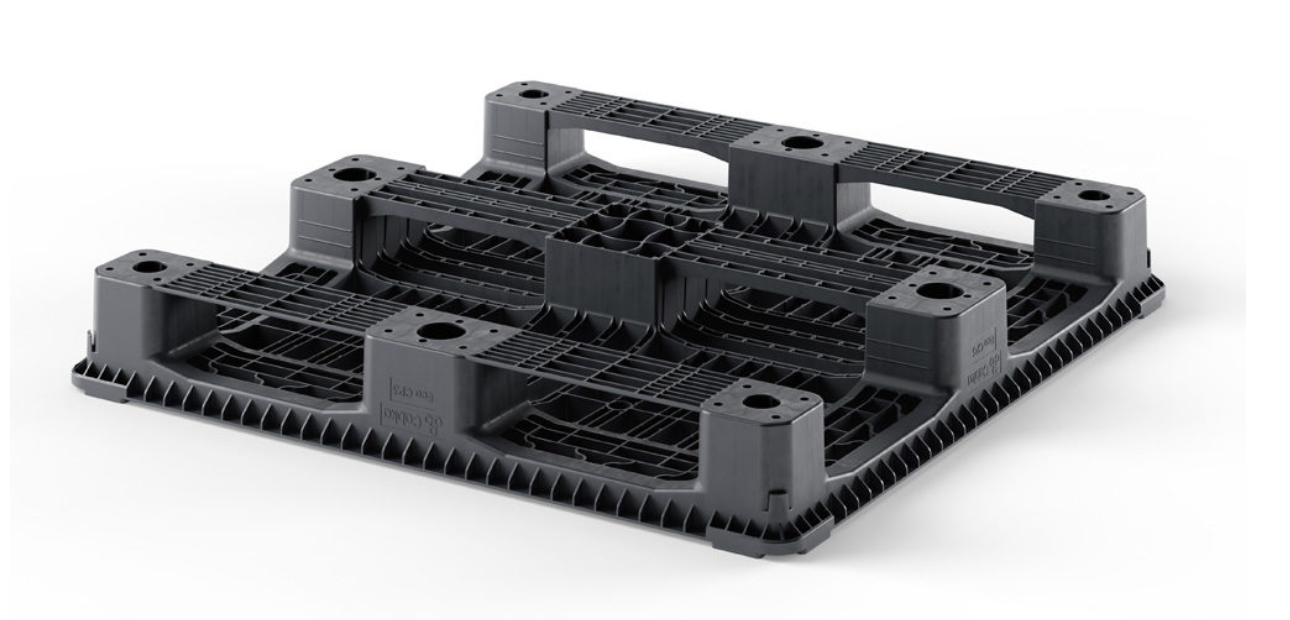

To make the lower deck of the pallet more resistant, Cabka has raised the number of ribs of each runner and increased the corner radius of the runner's feet. (Image: Cabka)

The five-runner pallet Eco CP9 is even more stable than the CP3 and has a similar construction. The weight of the pallet is 14 kilograms, and its construction makes it suitable for stacking in blocks, as the supporting frame distributes the weight to the load below.

With their pallets, Cabka sets the focus on sustainability and circular economy. On the one hand, the pallets already are made of recycled plastics. On the other hand, after the end of their service life, they are also recycled again and remain in circulation. EcoVadis awarded the company a Silver Rating for its efforts.

When it came to improving and creating a new generation of pallets, the focus was on integrating suggestions from users within the chemical industry, as Jean-Marc van Maren, Chief Product Officer at Cabka, explains:

“They have improved the design for the next generation of Eco CP3 and CP9 pallets. With the input of the world's leading chemical industry companies, we have made these sustainable load carriers more reliable and safer than existing solutions on the market.”

A functional circular economy and sustainable added value however require the widespread use of the pallets.