Are you aware of the factory's manufacturing process behind hot dog trays? Although simple, these hot dog holders undergo a rigorous process to transform from an idea to a tangible product. A well-designed hot dog tray not only hones in the serving aspect but also adds a press to brand recognition. At the heart of a well-designed hot dog serving tray lies a combination of expertise, experience, attention to detail, and a lengthy process.

Let us start the blog without further ado and present the actuality behind manufacturing these sales Hot dog serving trays.

Materials Used in Manufacturing Hot Dog Serving Trays

The first step in manufacturing hot dog serving trays is selecting the appropriate materials. The choice of material depends on the desired properties of the trays, such as durability, cost, and environmental impact. Common materials used include:

1. Plastic

Plastic is a popular choice due to its durability and versatility. High-density polyethylene (HDPE) and polypropylene (PP) are often used because they are lightweight, sturdy, and easily molded into various shapes and sizes.

2. Paperboard

For eco-friendly and disposable options, paperboard is a preferred material. It is biodegradable and can be recycled, making it a sustainable choice. Paperboard trays are often coated with a thin layer of polyethylene to enhance their strength and resistance to moisture.

3. Aluminum

Aluminum trays are known for their durability and resistance to heat. They are commonly used when trays need to withstand higher temperatures, such as in food trucks and catering services.

4. Biodegradable Materials

With growing environmental concerns, many manufacturers are turning to biodegradable materials like bagasse (sugarcane fiber) and PLA (polylactic acid) derived from corn starch. These materials offer an eco-friendly alternative without compromising on functionality.

The Manufacturing Process

The manufacturing of hot dog serving trays involves several key steps, each ensuring that the final product meets high quality and performance standards. Here is an overview of the typical manufacturing process:

1. Design and Prototyping

The process begins with designing the tray. This involves creating blueprints specifying the tray's dimensions, shape, and features. Advanced software tools are used to create 3D models, allowing designers to visualize the final product. Once approved, a prototype is produced using rapid prototyping techniques like 3D printing. This prototype helps identify design flaws and make necessary adjustments before mass production.

2. Material Preparation

Depending on the chosen material, the preparation process varies. Raw plastic pellets are melted and mixed with colorants and additives to achieve the desired properties for plastic trays. For paperboard trays, large rolls of paperboard are cut into sheets and coated with polyethylene if needed. Biodegradable materials undergo similar preparation processes, ensuring they are ready for molding or forming.

3. Molding and Forming

The prepared material is then molded or formed into the desired tray shape. The techniques used vary based on the material of the hot dog serving tray:

Injection Molding for Plastic Trays

Injection molding is commonly used for plastic trays. The molten plastic is injected into a mold cavity, which cools and solidifies into the tray's shape. The mold can produce multiple trays simultaneously, increasing production efficiency.

Die Cutting and Forming for Paperboard Trays

Die-cutting and forming techniques are used for paperboard trays. The paperboard sheets are fed into a die-cutting machine, which cuts them into the desired shape. The cut pieces are then folded and glued to form the Paperboard hot dog serving trays.

Thermoforming for Biodegradable Trays

Thermoforming is often used for biodegradable materials. The material is heated until pliable and then formed over a mold using vacuum or pressure. Once cooled, the trays are trimmed to remove excess material.

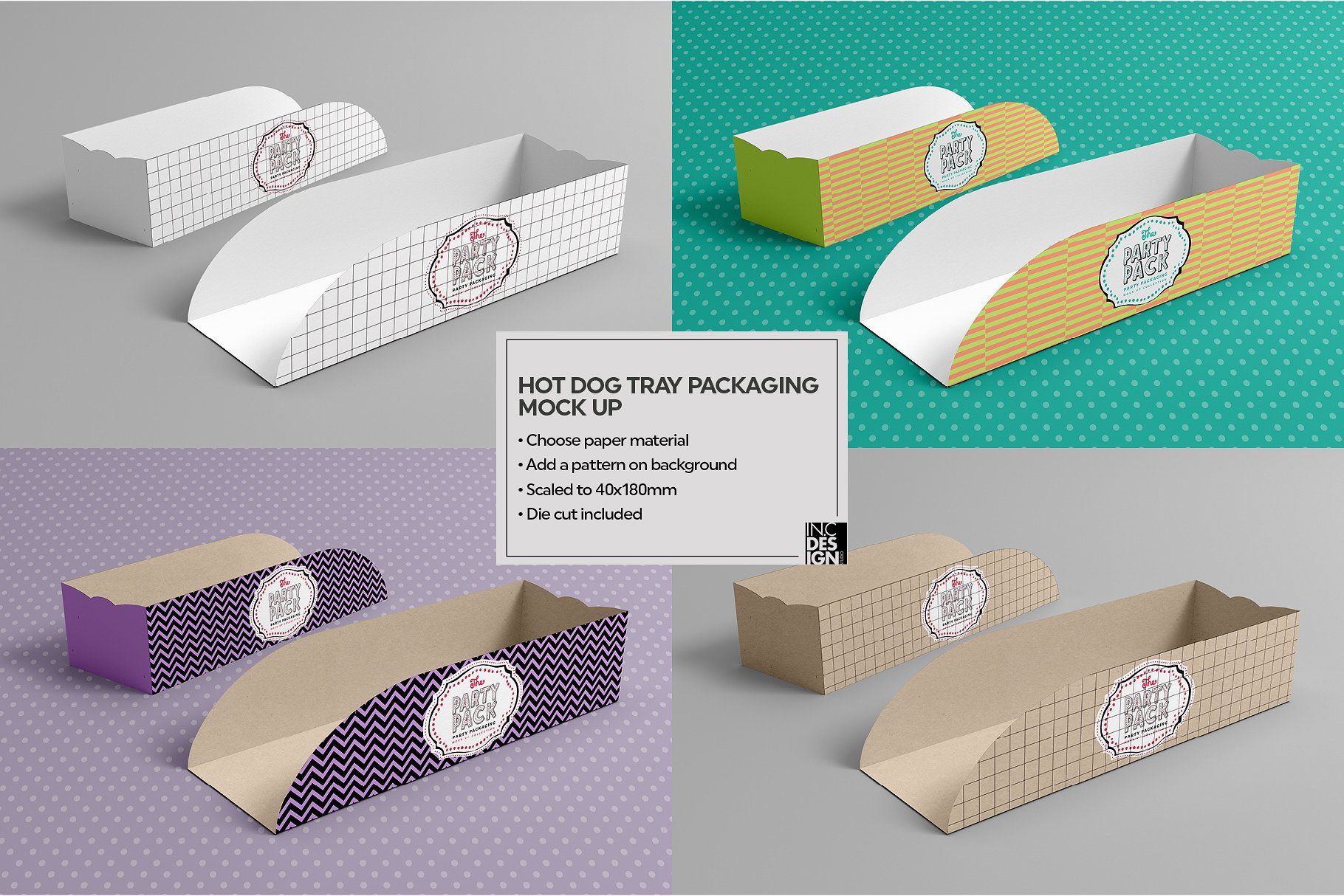

4. Printing and Customization

Once the trays are formed, they undergo printing and customization. This step is crucial for branding and enhancing the visual appeal of the trays. Advanced printing techniques, such as flexographic or offset printing, apply logos, graphics, and other design elements. Customization options may include embossing, debossing, and using special coatings for added durability and aesthetics.

5. Quality Control and Inspection

Quality control is an integral part of the manufacturing process. Each tray undergoes rigorous inspection to ensure it meets the required standards. This includes checking for defects, measuring dimensions, and testing the tray's strength and durability. Any trays that do not meet the quality criteria are discarded or reworked.

6. Packaging and Distribution

The final step in the manufacturing process is packaging and distribution. The trays are packed in bulk and labeled for shipment. Efficient packaging ensures that the trays remain intact and free from damage during transportation. They are then distributed to various customers, including restaurants, food trucks, catering services, and retailers.

Conclusion

The manufacturing of hot dog serving trays is a complex process that involves careful material selection, precise design, and rigorous quality control. Each tray type, from plastic and paperboard to biodegradable materials, serves a specific purpose and meets different needs. As technology and environmental awareness continue to advance, the future of hot dog serving trays looks promising, with innovations that enhance both functionality and sustainability.

By understanding the manufacturing process, businesses and consumers alike can appreciate the effort and expertise in producing these essential items, ensuring that every hot dog is served with convenience and style.