Brand enhancement specialist API has increased its holographic foil and film manufacturing capabilities after completing a recent £0.5 million investment at its Livingston facility in Scotland.

The programme followed the sale of its security holographic business in 2016 and was part of a large investment that has seen the Livingston site gain new capabilities in holographics and embossing, while also creating new jobs at the plant.

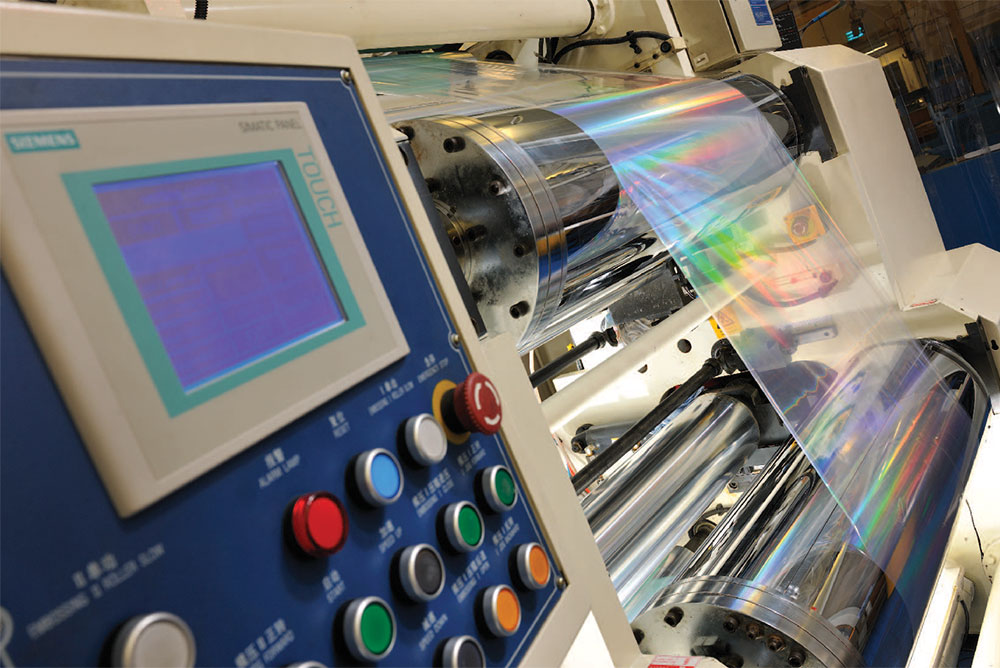

Completed ahead of schedule, Livingston is now the key holographic manufacturing site in Europe for API, providing packaging customers with world-leading decorative holographic foils and films from three separate coating lines and a seamless embosser.

“The addition of holography to our manufacturing has built naturally on our existing hot and cold foiling capabilities as well as broadening our product scope,” explains Colin Boyd, General Manager at API Livingston. “This has enabled us to offer our customers a seamless transition during our development programme and now provide an extended packaging product offer.”

Since the development, the Livingston site has also been focusing on lead-times and best practice in order to ensure it meets the demanding standards of quality and technical knowledge across its existing and new holographic products.

In addition, the increased capability has been an opportunity for the existing workforce to gain new skills, manufacturing foil and laminate products across the API portfolio.

Commenting on the development, Dino Kiriakopoulos, CEO of the API Group, said: “API has a world-class offering of laminates, foils and holographics for enhancing our customers’ brands and packaging. The development of Livingston for the production of decorative holographic foils and films – all completed ahead of schedule – ensures maximum synergies across our product range so that we can deliver the innovative packaging products our customers demand.”