Just in time for FachPack 2024 in Nuremberg, two strong partners present a sustainable comprehensive concept for optimizing the maturation process of naturally aged cheese. The core of the solution is the proven VSM® vacuum packaging machines from MBM innovations and Pack-Age®, an innovative, high-performance maturation membrane from dsm-firmenich. One of the many advantages is that cheese can now develop the flavour and texture of naturally matured cheese without continuously treating the cheeses with traditional cheese- coating.

The Pack-Age® membrane significantly contributes to the sustainable optimization of the cheese production process, specifically helping to prevent 5 to 10 percent of cheese loss during the maturation and processing stages, especially when removing the cheese coating before slicing the cheeses." highlights Sabrina Mayer-Mai, responsible for strategic marketing at MBM.

But that’s not all: The bioprotective performance of this packaging concept has been proven to delay unwanted mould and yeast growth. Moreover, once the cheese has matured with Pack-Age®, the membrane can easily be removed and fed into established plastic recycling streams.

The innovative concept...

...is a full-fledged yet significantly more sustainable alternative to the widely used PVA (polyvinyl alcohol) protective cheese coating. This coating is regularly renewed, and in a final step removed before the cheeses go to market. Besides this labour-intensive process, removing the coating often results in cheese lost as well. "Thanks to our breathable Pack-Age® membrane, we can reduce food waste and save valuable resources such as milk, water and energy. At the same time, we are also enhancing product quality.” explains Mark ten Cate, product application expert for cheese, coatings, and packaging at dsm-firmenich. The multinational formed in 2022 through a multi-billion-dollar merger between Dutch vitamin manufacturer DSM and Swiss fragrance and flavour company Firmenich, is committed to improving the health of people, animals, and the environment through bio-science. Key markets include food and beverages, animal nutrition and health dietary supplements, infant nutrition, and personal care.

For Augsburg-based MBM innovations, which operates in around 17 countries, dsm-firmenich has been a highly valued partner in cheese expertise for over ten years. Sabrina Mayer-Mai adds: “dsm-firmenich offers a wide range of cultures, enzymes and further solutions, helping customers create the perfect taste and texture, including sliceability and grating performance. Our goal is to produce high-quality dairy products that are attractive, safe, healthy, and efficient – this unites us and is our recipe for success in the projects we have implemented so far!”

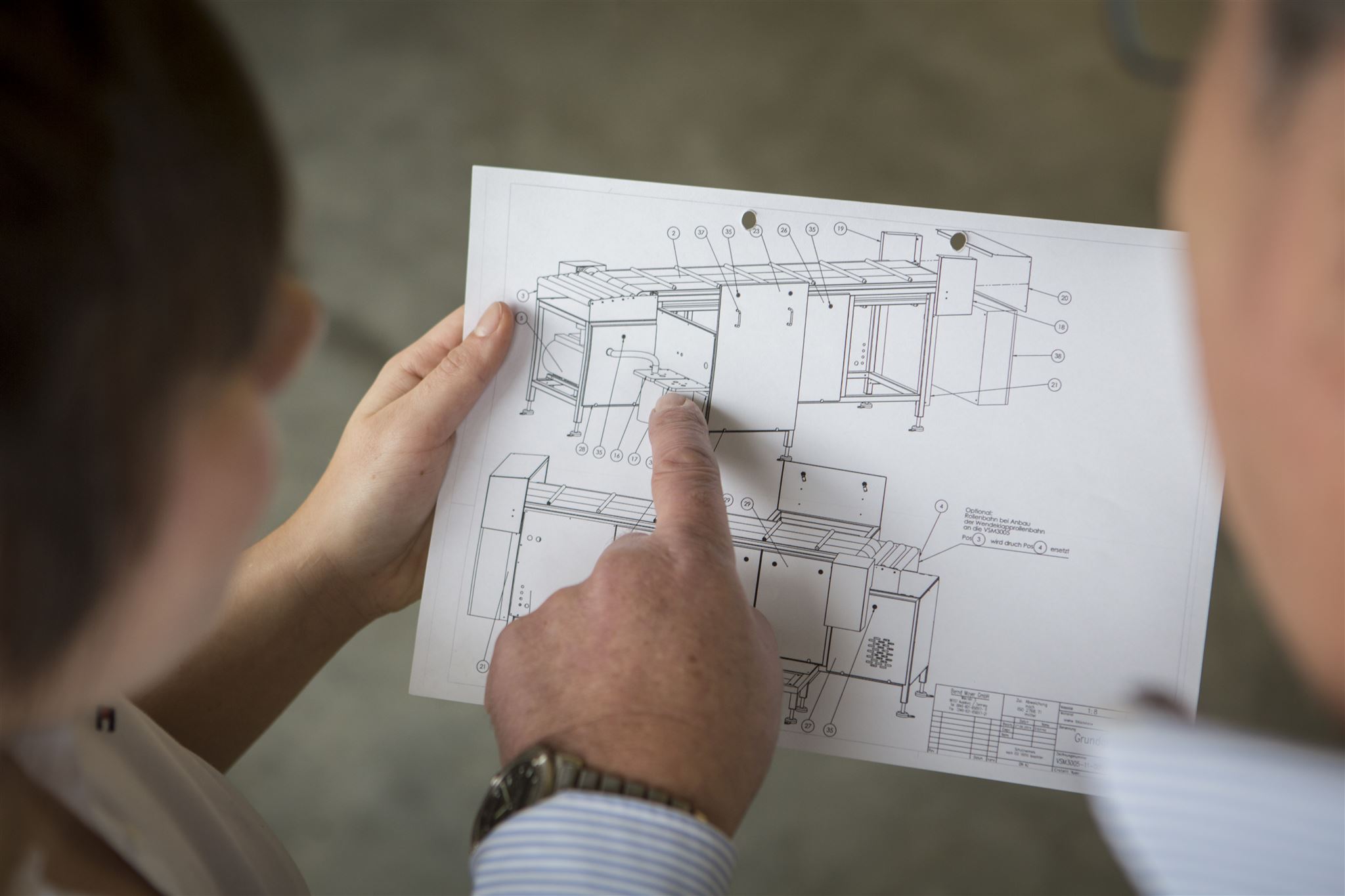

MBM, a family business now in its third generation, specializes in designing and manufacturing customized vacuum packaging machines with the VSM® system. Its core market has been vacuum packaging for cheese maturation for over half a century.

Pack-Age®: More than just a maturation membrane

Producers of naturally matured semi-hard and hard cheeses such as Gouda, Tilsiter, Havarti, or Manchego benefit from the unique combination of VSM® technology and innovative Pack-Age® membranes, which are perfectly tailored to the machines. This intelligent combination guarantees optimal packaging results and ensures ideal maturation conditions for premium products.

"Currently, cheese producers lose between three and ten percent of their production due to spoilage, removal of coating, and moisture loss during natural maturation," says Mark ten Cate. However, cheese maturation membranes based on Pack-Age® deliver more: Compared to PVA-coated cheese, cutting losses are reduced by up to seven percent post-maturation because the need to remove the protective layer, along with associated cheese losses, is eliminated. Enabling the most efficient natural cheese ripening process improves customers’ bottom line. In summary, Pack-Age® helps dairies getting up to ten percent more out of the milk.

In the end, not only does yield improve, but the overall cheese quality increases: The unique membrane solution of Pack-Age® allows hard and semi-hard cheese to breathe during maturation, developing its characteristic, full-bodied flavour. The risk of contamination is also reduced, as human intervention in the production process is significantly minimized. A comparative tasting, by the way, showed that cheese matured with Pack-Age® delivers the same flavour and texture balance as naturally matured cheese – but in a much more sustainable way.

For maximum product, process, and packaging safety…

... dsm-firmenich and MBM have combined their synergies, perfectly aligning machines and packaging material. The fully and semi-automated VSM® packaging solutions are thus the ideal choice for various cheese formats – whether round or square formats or sticks.

MBM's atmospheric vacuum system ensures gentle handling while maintaining the high quality of the vacuum. This offers significant advantages for delicate products like premium cheese, in terms of product quality, vacuum security, handling, and resource efficiency. Evacuation is carried out using special suction nozzles directly within the bag. The entire evacuation process occurs under normal atmospheric pressure, without a vacuum chamber. Even with large formats, wet bags, or thin, delicate films like Pack-Age®, the VSM® vacuum station ensures a reliable, crease-free seal: "Pack-Age® membrane contain no polypropylene (PP) or polyethylene (PE), so they do not melt easily. However, thanks to the bi-active sealing process, we can still guarantee perfect sealing results, even with materials featuring demanding membrane structures," confirms MBM Product Engineer Julia Mayer.

Sustainability is key – not just in materials, but also in machines

It comes as no surprise that MBM's machines impress in terms of sustainability. "The VSM® vacuum system alone saves between 36 and 50 percent of energy compared to other vacuum systems with the same performance," explains CEO Bernd Mayer. To put this into perspective: 36 percent corresponds to the equivalent of the average annual electricity consumption of a four-person household in Germany.

Key factors driving resource and energy efficiency include the impulse sealing system, the small vacuum pumps, and the absence of fresh water for cooling and air-blowing for bag opening. There are no preheating times, and no permanently heated plates, which has a positive impact not only on energy consumption but also on machine availability.

Additional benefits include the high vacuum quality and optimal sealing results. "Our goal is always to minimize product, material, and resource waste – and thereby reduce the CO2 footprint across the entire value chain, from manufacturing our machines to packaging our customers’ products," emphasizes Bernd Mayer. Contributing to this are the machines' durability, an efficient single-bag process to reduce film and cheese waste, and the use of the thinnest possible films, which still provide high stability and optimal product protection.

At FachPack 2024 in Nuremberg...

...MBM innovations will provide comprehensive information on its machine concepts and Pack-Age® at hall 2, booth 432. Sabrina Mayer-Mai expects strong demand for this overall solution in the coming months: "Naturally ripened cheese remains popular. Besides the great taste experience, cheese lovers are increasingly seeking products that are natural, sustainably produced, and packaged.”

In addition, MBM presents itself as a powerful provider of automation technology. The product and service portfolio ranges from individual conveyor belts and vacuum testers to complete turnkey solutions "Made in Germany."

Once packaged with MBM machines, cheese can be placed directly into special ripening crates. The advantage: These crates require less space compared to traditional wooden racks and offer better ventilation. “Combining ripening crates with fully automated handling systems could be a key topic for visitors at our stand,” reveals Sabrina Mayer-Mai.

About MBM Innovations GmbH

For over 60 years, the company has stood for innovation, quality and expertise in mechanical engineering. Now in its third generation, the long-standing Augsburg-based company combines the down-to-earth values of a family business with a spirit of innovation and modern entrepreneurship.

MBM was founded in 1961 as Sebastian Mayer Maschinenbau GmbH in Augsburg, focussing on special machine construction and machining activities. The development of the VSM® vacuum system in 1971 and the construction of the first vacuum packaging machine with the VSM® system marked the beginning of the success story of VSM® machines in the cheese ripening sector. Other milestones in the company's history include the construction of the first VSM® vacuum packaging machine with automatic bagging using a bag magazine in 1986 and the launch of the first VSM® vacuum packaging machine with fully automatic bag feeding in 1997. The company was renamed MBM innovations GmbH in 2017.

Today, MBM is a performance-driven and reliable partner for customers all over the world with its semi-automatic and fully automatic vacuum packaging machines. The focus is always on developing the best possible packaging solution for the respective requirements. All models are manufactured at the Augsburg site.