Screw design provides more performance and low energy consumption

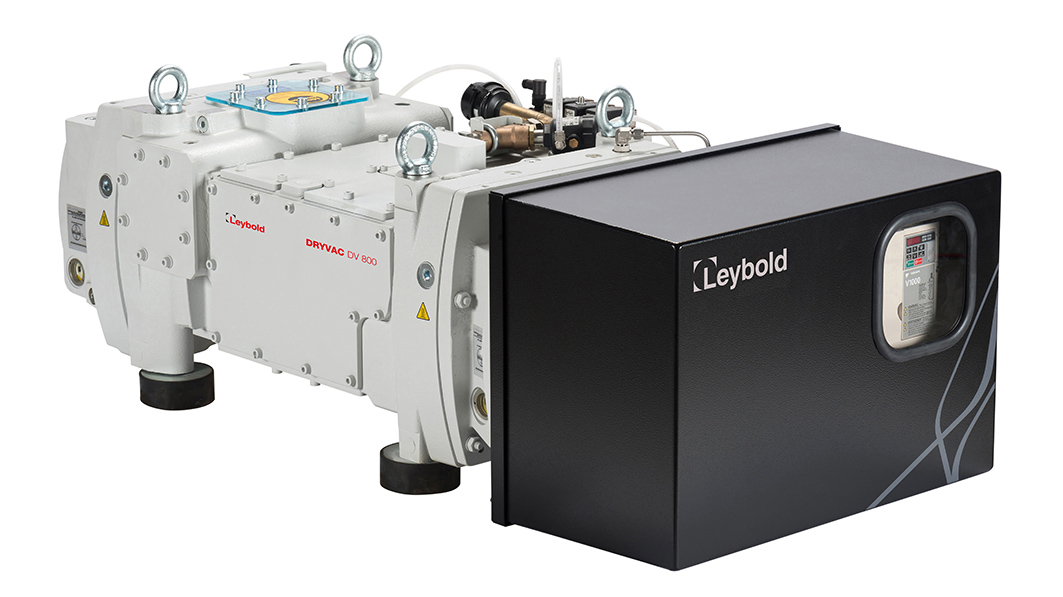

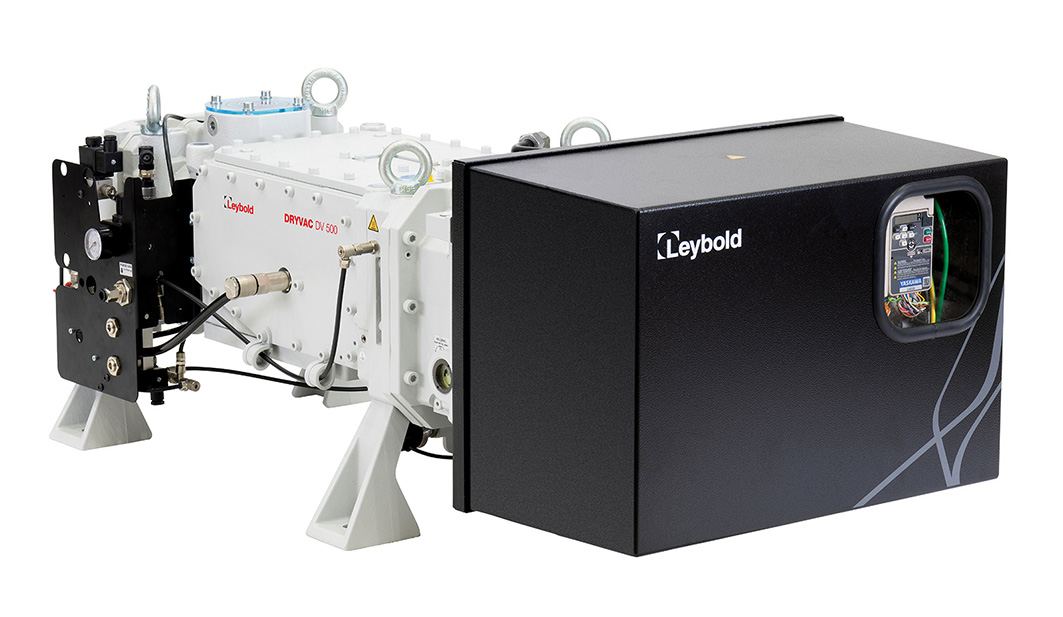

Cologne, June 2021 – The new screw vacuum pumps DRYVAC DV 500 and DV 800 will be presented by Leybold in spring 2021. These vacuum pumps compress completely dry, i.e. without operating lubricant in the compression chamber and are therefore ideally suited as backing pumps in food packaging or in pumping sets in heat treatment or coating systems, as they have significant advantages over oil-lubricated piston or rotary vane vacuum pumps.

Minimal maintenance effort Thanks to their screw design with a specially adapted variable pitch, they work extremely efficiently due to their low power consumption, require minimal maintenance compared to oillubricated vacuum pumps and thus minimize operating costs. The robust screw vacuum pump is also characterized by high particle and condensate compatibility.

Consistently high pumping speed over the entire vacuum range As a pioneer in dry vacuum technology, Leybold has several different screw vacuum pumps in its product portfolio. In contrast to oil-lubricated piston or rotary vane vacuum pumps, it offers a temporally stable pumping speed curve. The DRYVAC DV 200, 300, 450 and 650 portfolio has now been supplemented by the more powerful DV 800 and the highly energy efficient DV 500.

Significantly more performance The DRYVAC DV 800 is based on Leybold's proven DRYVAC DV platform and sets a benchmark in this size class. The fact that the DV 800's dimensions are directly derived from proven DV 650-models makes changeover and integration easier for the user. The DV 800 opens up new possibilities for applications where a higher pumping speed is required. In traditional markets, this is the case in many applications, such load locks or packaging machines. In new areas, such as battery manufacturing, a higher process speed means cash for the customer.

Optional monitoring via a cloud platform The DRYVAC DV 500 and DV 800 are equipped with an easily adaptable and networkable frequency converter and IE3 motors. Monitoring via a cloud platform can also be easily implemented on request and is available as standard from Q3. The compact and well thought-out construction of the DRYVACs enables a Roots vacuum pump RUVAC to be easily installed as a booster. The pump combinations DV 1200 and the new DV 1600 round off the portfolio for even higher pumping spee

About Leybold Leybold is a part of the Atlas Copco’s Vacuum Technique business area and offers a broad range of advanced vacuum solutions for use in manufacturing and analytical processes, as well as for research purposes. The core capabilities centre on the development of application- and customer-specific systems for the creation of vacuums and extraction of processing gases. Fields of application are secondary metallurgy, heat treatment, automotive industry, coating technologies, solar and thin films such as displays, research & development, analytical instruments, food & packaging, as well as a multitude of other classic industrial processes. About Atlas Copco Group Our industrial ideas empower our customers to grow and drive society forward. This is how we create a better tomorrow. Atlas Copco is a global industrial group, founded in 1873 in Stockholm. In 2020, we had revenues of BSEK100 (BEUR 10) and at year end about 40 000 employees.