A comprehensive presentation of the various ‘vision cells’, each dedicated to a specific product line, with a wealth of technological innovations to streamline management and broaden the field of application.

A first for the fair: integration between SACMI DMD digital printing and the ECLIPSIM DECO metal sheet vision system

Building synergies to stay ahead of market developments is what SACMI is all about: hence our presentation, at Metpack 2023 (Messe Essen, 2-6 May), of the latest range of metal packaging vision systems.

A fresh design philosophy built around customer needs focuses on modularity, space savings and effective systems operation. In parallel, SACMI delivers increasingly accurate controls, with dedicated systems for each specific product.

Integrating digital printing with vision inspection

Key developments on show at the fair include the first solution on the market to integrate both production and quality control of digitally decorated metal sheets.

SACMI DMD is the digital alternative for decorating the metal sheets used to make packaging in food, beverage and other industries.

Why go digital? Traditionally screen-printed, decoration is a vital packaging component as it enhances product quality and brand recognizability. Hence the need for ever-increasing customization which, in turn, has led to generally smaller batches, consequently reducing the efficiency of traditional decoration lines (high-speed systems that can produce more than 7,000 sheets per hour but are too rigid when small batches and fast changeovers are required).

DMD is revolutionary in two ways, Firstly, it can decorate at rates as high as 2,500 sheets/hour). Secondly, it releases decoration from the rigidity of conventional systems (size changeover times slashed, no excess stock).

Now available with heads offering resolutions as high as 600 dpi, SACMI proposes a DMD that is - for the very first time - integrated with the ECLIPSIM DECO vision system. The advantages? Primarily, with SACMI, manufacturers can count on a sole provider who guarantees quality, reliability and worldwide assistance. Secondly, this pairing lays the foundations for ‘smart’ line management, which begins with the customer's order placement and continues with proactive (and, in the future, retroactive) control of any production drifts.

Intelligent, light, dedicated: the complete range of SACMI vision systems for metal

SACMI provides the market’s most comprehensive range of metal packaging inspection systems. That means coated, lithographed sheets yet also caps, lids, containers and cans. All these systems share the latest-generation CVS (Computer Vision Software) and patented solutions (Chrometriq and ElioScan) that deliver the best reliability in the metal inspection field.

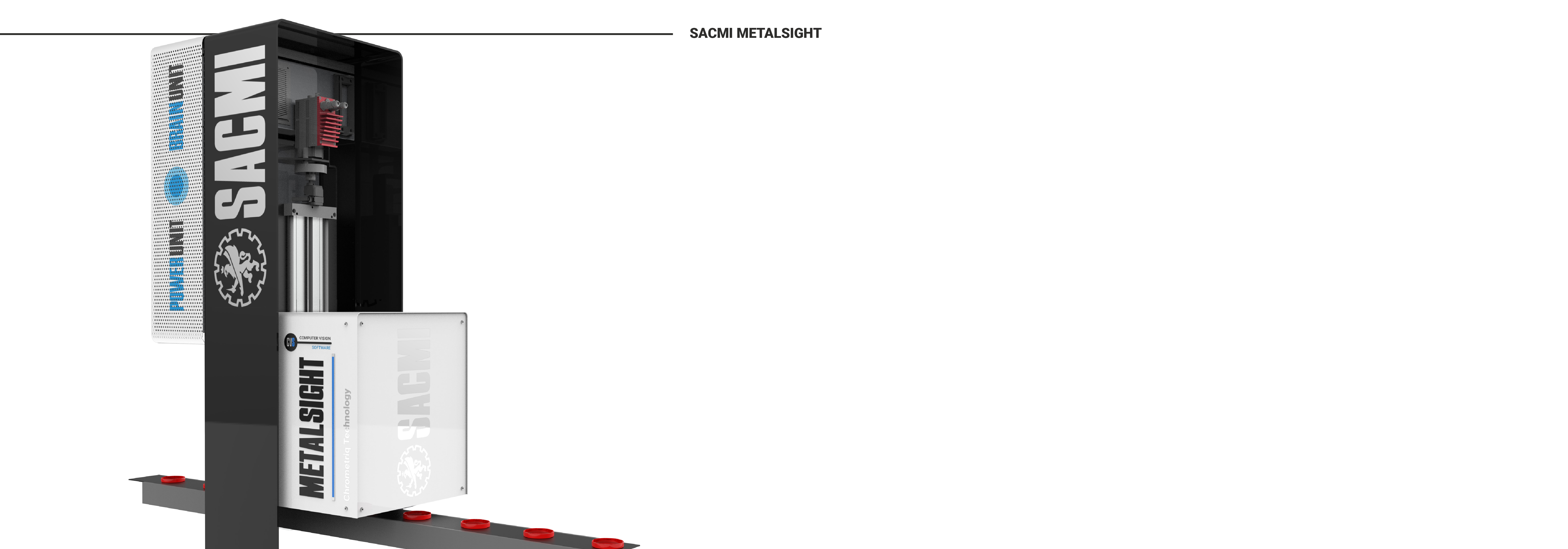

Modular and flexible, fast and precise: SACMI has now enhanced all its systems in terms of both technology and scope. The up-to-the-minute systems on show at the fair feature several innovations such as the lighter, more compact architecture of the electrical panel. SACMI also presents MetalSight, the new all-in-one platform that summarizes the SACMI approach to vision systems for metal... an approach that begins with the customers’ needs.

Metpack visitors will have a unique opportunity to see a range of inspection cells, each dedicated to a specific product line.

And that’s not all. These systems are increasingly used on production lines and SACMI now takes things to the next level on the ‘control’ side with a new operator interface. Called Classy-AI, it features advanced artificial intelligence algorithms that classify defects and generate warnings and statistics in real time. This means operators can run the systems, even if they’re not vision system experts, with a valuable helping hand from an interactive dashboard.