- PE film extruders consumed over 7.4 million tonnes of polymer in 2016

- Polyethylene film accounts for 80% of film products manufactured in Europe

- Future challenges to the PE film industry

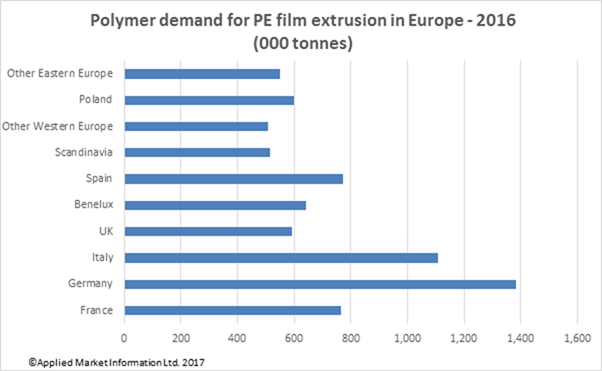

The polyethylene film industry in Europe has continued to grow at a steady rate over recent years. Despite trends to use more linear and metallocene materials enabling film producers to make thinner films, the volume demand has continued to rise to reach over 7.4 million tonnes of polyethylene materials consumed for film extrusion in 2016, a 1% rise on the previous year.

Such positivity is best exhibited in Germany, which is the leading country for polyethylene film extrusion in Europe. Germany has seen its film extrusion industry pretty much maintain its status throughout the financial crisis and the subsequent Eurozone crisis with demand in 2016 finally surpassing pre-crisis levels. In contrast Italy, which previously had been the largest market for the production of PE film, film extruders have struggled to regain volumes since the financial crisis with the market still 24% smaller than it was in 2007.

It is estimated that over 80% of all the film products manufactured in Europe are based on polyethylene grades. The growth, and continued dominance of polyethylene in this segment of the market is driven by the development of ever more sophisticated resins, including linear varieties, a wide range of copolymers, and improved grades of conventional HDPE and MDPE resins. Linear grades of polyethylene, including metallocenes are now believed to account for the majority of feedstocks used by film extruders as the greater availability and lower cost of C4 linear grades has increasingly replaced the use of conventional LDPE. AMI estimates the split of demand amongst film extruders as 44% for LL grades, 43% conventional LDPE and 13% HDPE/MDPE.

The polyethylene film industry continues to evolve and change through merger, acquisition and new investments. Staying up-to-date with the changes and developments in this market is a huge challenge. However, AMI’s directory of Polyethylene Film Extruders in Europe helps you track these changes as it provides detailed information on over 1,200 polyethylene film extrusion sites in Europe. Within the directory you will find contact (telephone, fax, email, address and website) information and production (polymers processed, film manufactured and film widths) information.