Connectivity between production and automation systems in process manufacturing and the Internet is constantly increasing. In order to fully protect manufacturing systems against cyberattack, B&R has further enhanced the user management features of the APROL process control system. Distributed, autonomous security cells provide simple yet efficient protection for systems against malicious software and attacks from hackers.

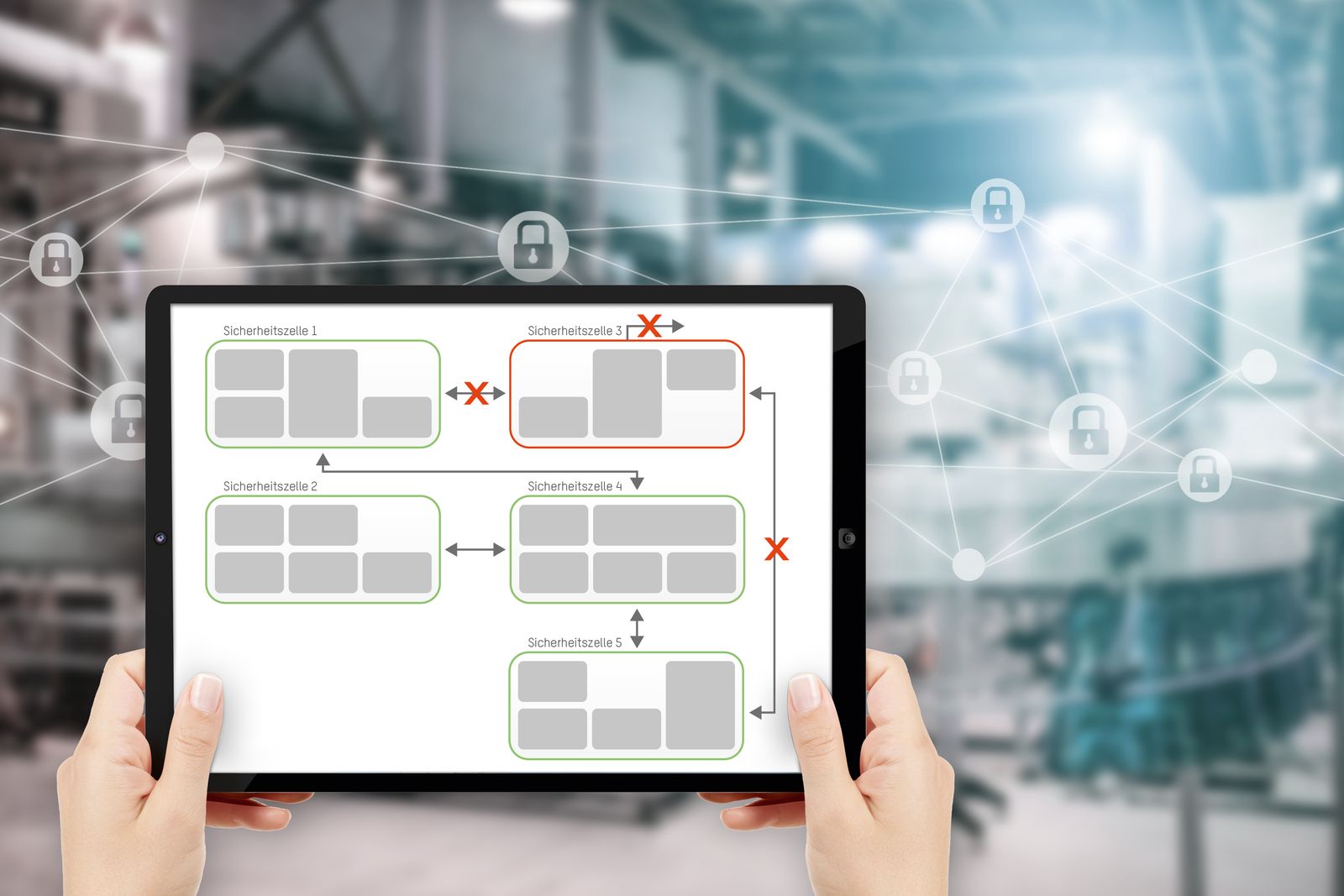

In order to protect extensive manufacturing systems against cyberattack, they are divided into security cells. If one security cell comes under external attack, all other cells can continue to run unimpeded. This minimizes possible damage while simultaneously increasing the availability of the manufacturing system.

Security cells provide effective protection against hacker attacks and cyber threats

To achieve maximum protection, the manufacturing system must first be divided into autonomously functioning process cells. These consist of production-relevant zones, sections, sub-areas or subsystems. One or more of these process cells are then combined into security cells. The flexible client/server architecture of APROL allows up to 64 of these security cells.

LDAP for each runtime server

The advanced multi-runtime server architecture of the APROL process control system ensures that all required systems operate independently. Each multi-runtime server includes its own LDAP server (389 Directory Server) that provides cybersecurity, allowing systems and subsystems within a safety cell to be operated even without an external network connection.

About B&R

B&R is an innovative automation company with headquarters in Austria and offices all around the world. On July 6, 2017, B&R became a business unit of the ABB Group. As a global leader in industrial automation, B&R combines state-of-the-art technology with advanced engineering to provide customers in virtually every industry with complete solutions for machine and factory automation, motion control, HMI and integrated safety technology. With Industrial IoT communication standards like OPC UA, POWERLINK and openSAFETY as well as the powerful Automation Studio software development environment, B&R is constantly redefining the future of automation engineering. The innovative spirit that keeps B&R at the forefront of industrial automation is driven by a commitment to simplifying processes and exceeding customer expectations.

For more information, visit www.br-automation.com.

Press contact:

Corporate Communications

t +43 7748 6586-0

press@br-automation.com

B&R Industrial Automation

B&R Strasse 1, 5142 Eggelsberg, Austria