Successfully launched at Drinktec 2017, the world’s leading trade fair for the beverage and liquid food industry, the Super Combi is designed and engineered as a single smart solution. It makes life easier for producers of water and CSD beverages, via integrated data- driven intelligence, making optimum performance easily and continuously achievable across the entire production process.

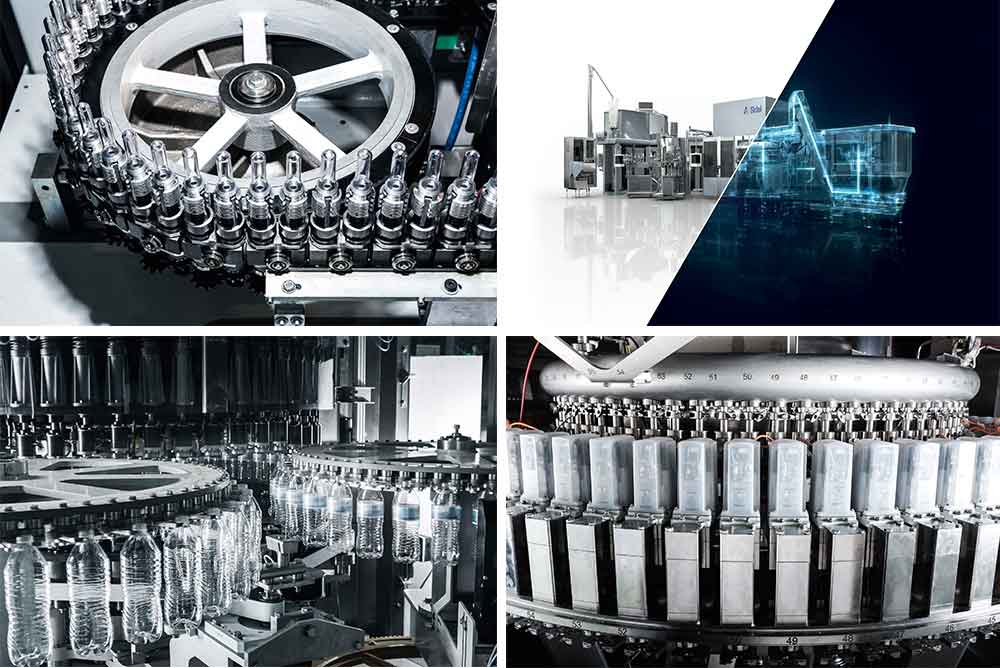

Sidel Super Combi is the next generation solution integrating five process steps: preform feeder, blower, labeller, filler/capper and cap feeder into an all-in- one smart system. To deliver this self- optimising performance and increased long-term value, it combines intelligent automation with innovative technologies of connected machines and data-analytics management, leading to optimised production and maintenance services.

A smarter solution for today’s demands

Consumer preferences are broadening and overall demand is increasing due to unprecedented population growth, increased consumer spending power and growing demand for personalisation of products in terms of design and taste. The ability of production solutions to satisfy output requirements for new products efficiently, while implementing technologies that improve long-term viability, has become vital to manufacturers’ success.

Beverage producers simply want a solution that does the thinking for them and acts on their behalf. This is where Sidel Super Combi, with its data-driven intelligence and advanced automation, provides the answers. For instance, autonomous regulation is achieved via Sidel Intelli-adjust™ controlling the system’s performance and automatically applying adjustments wherever they are needed. Long-term enhancement without compromising on simplified operation, reduced maintenance time and minimal downtime are all also possible thanks to intuitive interfaces such as augmented reality guidance and GPS localisation.

For instance, for improved reactivity of the operator, it has an automated alert system to provide advanced timely reports through the EIT™ (Efficiency Improvement Tool) audio and smart portables, on events such as changeovers, label or cap shortages and possible faults. Improved Root Cause Analysis (RCA) software enables intuitive intervention, making it easier for operators to solve problems quickly. Additionally, guided trouble-shooting reduces operator skill requirements and offers increased repeatability of changeover and maintenance procedures. By ‘learning from experience’, the Sidel InUse platform is able to predict potential failures and optimise maintenance plans. Accessible via smartphone or tablet with a dedicated mobile app - developed for both Android and iOS - the platform enables producers to share and interpret the data of connected equipment. This helps to speed up problem solving and offers the chance of timely detection of possible issues, as well as guidance for their successful resolution. The Super Combi also provides real-time access to the Sidel Big Data repository - where customer data is safely held under conditions of total cyber security - for refining its own prediction algorithms. This makes it possible to maintain, control and even improve the performance of main components and modules.

The lowest production cost per square metre

To ensure an even more sustainable production, the Super Combi has been entirely designed to minimise the use of resources. For example, the Super Combi blower - based on the Sidel Matrix™ platform - operates at high oven efficiency and minimal environmental footprint; yet pushing the boundaries of ultra-lightweight bottle production and handling, thanks to the labelling process now integrated in the solution. Consumption of electrical power is reduced by up to 45%, preform-heating time is lowered by up to 15% and, with the option of AirEco2 double air-recovery, a 35% reduction in the use of compressed air is also achieved. To further reduce the environmental footprint, the entire system is based on brushless motors. In addition, the new melter and glue control distribution on the labeller minimises the consumption. The OptiFeed® cap feeder system from Gebo Cermex, part of the Sidel Group, combines storage, elevation, orientation and high-speed feeding with energy savings, as its individual cap-elevating technology eliminates the need for compressed air and electronic fan systems during extraction.

Ergonomic, compact and easy to operate

The solution is designed for ease of operation, with its intuitive interfaces, ergonomic design and clear guidance on operations and maintenance activities for ongoing high levels of performance and uptime. Super Combi has been engineered to ensure operator access is immediate and safe, examples being the location of the preform feeder at ground level, or the labeller and cap feeder which are both designed for easier access. With the new ergonomic, compact design - up to 30% smaller when compared to standalone equipment - and increased visibility of all blocks, the Sidel Super Combi makes single-operator control possible.

Safer and more hygienic

With a strict focus on hygiene, packaging quality and beverage integrity, Sidel Super Combi ensures maximum food safety, a critical requirement for producers. Gentle handling of the preforms by the preform feeder ensure their original quality is retained. Similarly, positive handling of the bottles by the neck throughout the whole system and across a safe environment - from blowing to capping - guarantees optimal care. This enables higher bottle quality overall and maximises lightweighting opportunities. The integrated vision/rejection systems from preform to caps always ensure the best product quality, saving both raw materials and resources consumption.

Ultimate flexibility for improved uptime

The integration of innovative new technologies minimises changeovers on the Sidel Super Combi, which can be guided for improved speed and efficiency to keep the line running smoothly with minimal downtime. The simplified settings of the preform feeder, the quick release blowing moulds and a reliable high-speed reel auto-splicer, along with the sector based vacuum drum of the labeller, are just some of the ways that Sidel Super Combi makes changeovers easier and faster than ever.

Innovative labelling flexibility to minimise downtime

High-output production of beverages at high and very high speeds requires equipment that overcomes traditional obstacles to ensure continuous uptime. The Sidel Super Combi is the result of extensive innovation and improvements to the company’s existing labelling technology. With different machine configurations possible based on the output required, the new labelling process is highly efficient and provides unmatched process flexibility, the integrated labeller being able to carry out different labelling processes, including the application of PSL (pressure sensitive labels) and roll-fed labels.

The labelling process can be optimised to work with up to three stations running simultaneously or with a ‘master/slave’ setup, in which the one or two stations run while the designated ‘slave’ station remains idle - still achieving the nominal output. When a reel-change is required, the roles automatically switch. This creates a labelling process that delivers uncompromising continuous high-speed production with no product loss or reduction in speed of production resulting from reel- changes.

By utilising integrated equipment intelligence and innovative technologies from Sidel, the new Super Combi enables continuous production-optimisation and enhanced performance for producers of PET bottled water and CSD. This makes it the ideal way to maximise production and increase line efficiency while reducing TCO. It is yet another smart solution from Sidel. The next generation of water and CSD production is available now.