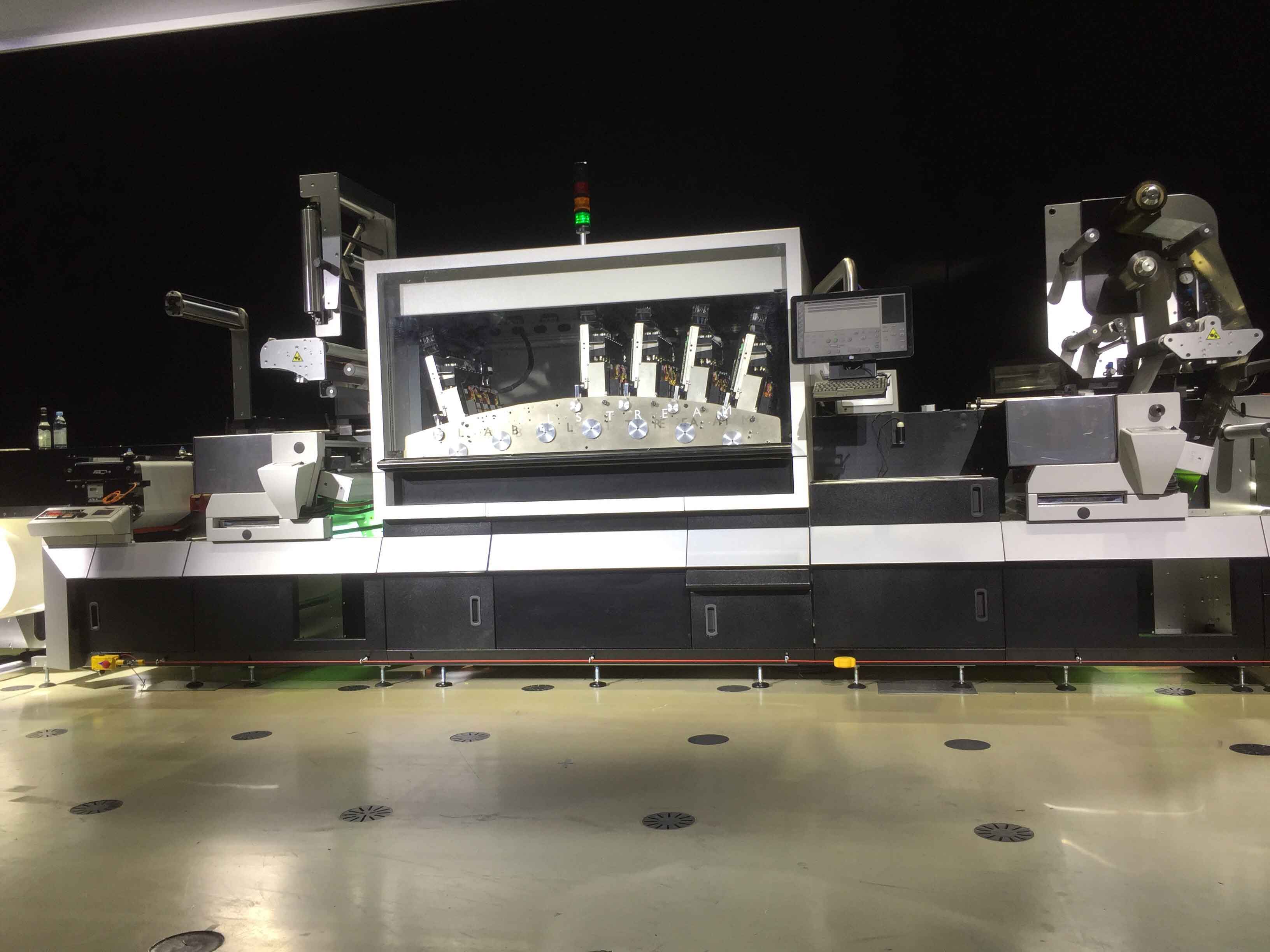

Cambridge, 19 th June 2018 The combination of speed, quality and reliability of the Xaar 2001+ U printhead made it the ideal choice for Canon’s entry into the digital label printing market, with the launch of its Océ LabelStream 4000 press.

The roll-to-roll industrial-scale UV inkjet press provides CMYK+W printing and features the latest Xaar 2001+ U printheads. Targeted at label and flexible packaging converters, it can print on a wide range of standard label stocks including PP and PE plus selected special substrates.

The Océ LabelStream 4000 has been developed in collaboration with label industry specialist, and long-standing partner of Xaar, FFEI, incorporating Xaar’s 2001+ U printhead technology.

“The support from Xaar has been a critical part of the success of this project, enabling us to integrate the Xaar 2001+ printhead and deliver the reliability and print quality label producers demand,” commented Andy Cook, Managing Director at FFEI.

Combining high resolution and proven TF Technology ink recirculation, the Xaar 2001+ U sets a new standard for print quality and reliability in single-pass digital printing. In order to deliver an optimal and flexible solution to customers, the Océ LabelStream 4000 uses different printhead variants from the Xaar 2001+ U family. The small drop size of the Xaar 2001+ GS6U provides crisp details in CMYK, whereas the larger drop size of the Xaar 2001+ GS12U achieves high opacity withwhite ink. This enables the Océ LabelStream 4000 to deliver an impressive 80% opacity (“alpine white) at speeds of 48m/min in its Graphics mode, and a 67% opacity (“true white”) in a faster Production mode at 68m/min.

Available in a number of configurations to suit different needs in labels and flexible packaging, the Océ LabelStream 4000 will launch in two widths at 330mm and 410mm.

Gerard Winn, Senior Product Manager at Xaar, said: “We are delighted that the Xaar 2001+ U printhead has been chosen as the technology behind the Océ LabelStream 4000. With its productivity, print quality and reliability in single-pass applications, it provides the performance and durability that label and packaging producers demand and need to get ahead of their competitors.”