Table of Contents

- Active Pouch

- Tamper evident and anti counterfeit pharma packaging.

- 3D printing used for Label Precision

- PepsiCo, Coke set for mini cans and PET bottles (150-180 ml) cola war this summer

- ElifCare: An environmentally friendly Packaging

Active Pouch

Sirane's active pouch for safe disposal of cancer drugs

- Sirane has developed Safe-hold™ Active Pouches- for the safe disposal of a cancer relief drug. The absorbent pouch uses a blend of absorbent materials and activated carbon cloth to ensure that the chemicals used in the drug can be safely immobilised. The patented design is simple yet effective, and has many uses.

- The pouch traps and deactivates anything it comes into contact with, allowing for the safe transportation and the safer disposal of potentially harmful drugs and chemicals.

- It meets all legislative guidelines.

- It is easy-to-use pouch ensures quick and easy handling to reduce packaging costs.

- It is available in standard and custom sizes also. It is available with sealed closure.

Tamper evident and anti counterfeit pharma packaging.

Over ten percent of medicines worldwide are counterfeit, according to a study by the US Food and Drug Administration (FDA). To tackle this problem, STI Group design a pharmaceutical packaging that patients, pharmacists and hospitals can rely on and that ensures that the product in their hands is an original product.

This pharmaceutical demo box was published in response to the EU's forthcoming, safety regulation affecting packaging materials. The safety features used on the box: a two-dimensional data matrix code, M-icon screening, micro-text, serialization, Braille, holographic foil, Twin ICI, QR code. The combination of as many visible and invisible security features as possible offers the best safeguard. This carton also features a combination of classic anti-counterfeiting measures and new solutions such as the Trustcode®. This optical element can be scanned with mobile devices and the authenticity tracked by means of an app. In addition to this, the supply chain can be monitored by track and trace. Microtext, ICI or a coating that is only visible under UV light are just few of the features that can be found on the packaging, some of which are only used if the means necessary to decode them are available. In the blister packaging inside the box candies are placed to symbolize pills. The serial numbers of the candies can also be seen on the metal layer. A "patient information leaflet" placed in the box helps to provide the security features in three languages (English, German, Hungarian).’ The closure of four-color offset printing packaging is reclosable tamper evident. A tamper-evident closure protects the product against tampering and swapping of medicines. For packaging filled by machines at the pharmaceutical manufacturer’s site, various designs are possible to implement this requirement. Despite the tamper evidence, it is still possible to reseal the box after it has been opened for the first time. In manual filling, a security label, which is damaged when the box is first opened, indicates that the packaging was already opened. The pharmaceutical packaging also has an individual serial number that is printed either at the packaging manufacturer’s site or during the packaging process at the pharmaceutical manufacturer’s site. The printing of an individual GS1 data matrix code allows the packaging to be tracked over the entire supply chain. The tamper evidence can also be checked with a smartphone using a special app.

3D printing used for Label Precision

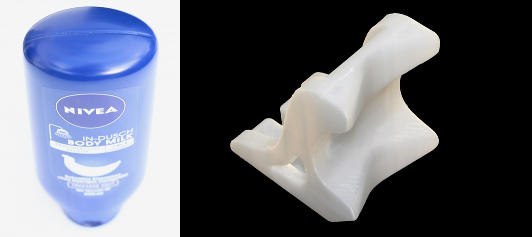

ReitlingerEngineering a German firm that works as a service provider for labeling machine makers, among others, uses the technology to make 3D printed clamps that hold products precisely in place for labeling. The new clamps are not only lighter and cheaper to make, they also require less time to manufacture. To attach a label to a

For German design engineering company ReitlingerEngineering one of the hardest parts of developing their line of automatic labeling machines was creating the clasping mechanism that allows the labels to be placed correctly. Their labeling machine was designed to hold bottles and retail packaging firmly in place while the label was applied. In order to do this the machines use a set of customized aligning jaws the exact size and shape of the packaging to clasp around it and hold it perfectly in place. This made sure that the label would be applied in the same exact spot each and every time. While the machine itself rapidly speeds up their customer’s production line, for ReitlingerEngineering and their customers developing the custom aligning jaws was a tedious, pricey and time-consuming process. In order for the aligning jaws to hold each retail package in place, ReitlingerEngineering needs to know the exact dimensions of the specific bottle or package that will be labeled. Unfortunately many of their customers often couldn’t supply an accurate 3D CAD model of the packaging, so designers at ReitlingerEngineering would need to hand measure the packaging and then manually generate a CAD model.

Once they had a 3D model, a CNC mill would be used to manufacture the front of the aligning jaws from a smooth plastic material. The new milled part would then need to be fit to an aluminum universal holder that would connect the jaws to the labelling machine. Not only was producing new aligning jaws costly to their customers, but it often slowed down the production time when one of them needed to be replaced or the company wanted to update their packaging.

Looking to reduce the cost of the machine and the time it took to manufacture new aligning jaws, ReitlingerEngineering used 3D scanning and 3D printing technology to come up with another solution. Their new process dramatically reduced the time required to produce new aligning jaws, and also cut the cost of designing new or replacement parts. Rather than try and get potentially incorrect packaging measurements from their customers or painstakingly design a CAD model from scratch, they turned to a powerful industrial 3D scanner which captured the packaging and converted it into a 3D model. ReitlingerEngineering used a David SLS-2 3D scanner to 3D scan the package which is easily and quickly be converted into a CAD model. Once they have a CAD model a new custom aligning jaw component is designed and turned into a 3D printable file that is then printed using a German RepRap X350 3D printer. The new process allowed ReitlingerEngineering to not only reduce cost and production time, but they were able to redesign the entire clasp itself. The new design completely eliminates the need for the aluminum support structures that would hold the plastic parts in place and instead turns it into a single part that can attach directly to the machine. This new all plastic part reduces the weight of the aligning jaws by nearly 70%. Not only does this dramatic reduction in weight speed the machine up and increase production cycles, but it puts less wear and tear on the labeling machine. Because the new aligning jaw is made from a 3D scan of the actual packaging the parts fit even more snuggly than the old parts which often required the need to adjust a set of tightening screws on the aligning jaw. Now ReitlingerEngineering is capable of producing new aligning jaws within a matter of days for a total production time reduction of 25% to 40% percent depending on the geometry of the product packaging.

PepsiCo, Coke set for mini cans and PET bottles (150-180 ml) cola war this summer

As consumers cut back on sugary drinks due to health concerns, PepsiCo and Coca- Cola are looking to introduce miniatures here to boost consumption and set the stage for a fresh cola war this summer.

As consumers cut back on sugary drinks due to health concerns, PepsiCo and Coca- Cola are looking to introduce miniatures here to boost consumption and set the stage for a fresh cola war this summer.

Priced lower than regular bottles, these mini cans and PET bottles (150-180 ml) will be used to lure consumers who don't want to have too much. Apart from regular distribution channels, the companies will be pushing these bite-sized treats through online marketplaces in the form of multipacks. Airlines may be targeted too.

The New York, Purchase-based food and beverage major will launch 150ml cans of Pepsi and Diet Pepsi at an introductory price of Rs 15 each. Multipacks of four cans are on the cards. Minis of carbonated beverages such as Mirinda and Mountain Dew may be launched later.

PepsiCo's rival Coca-Cola, on the other hand, is planning to launch slightly larger packs of 180ml cans and 300ml PET bottles that will be priced at around Rs 20 each. These will be across its sparkling beverages portfolio that consists of drinks such as Coke, Coke Zero, Diet Coke, Thums Up, Sprite, Fanta and Limca.

At present, a 200ml glass bottle of carbonated beverage by both these companies is priced at around Rs 12, a 300 ml glass bottle is priced at around Rs 15 and a 600 ml PET bottle comes for around Rs 35.Although the new smaller packs carry lower sticker prices, the consumer pays more per ml. This price-packaging architecture has proven to be big hit for cola makers in other markets where consumption is slowing down and a price hike is a big no-no.

"We will market these in smaller towns as well. Cans are aspirational for a lot of consumers. At a lower price point, these may push penetration because historically Indians have been concerned about the price-value equation between cans and glass bottles," said Prakash.

ElifCare: An environmentally friendly Packaging

ElifCare is an environmentally friendly-patented product, prevents waste of food delivering an outstanding performance in the matter of food protection and also provides assistance in reducing ecological footprints contributing most to sustainability in production, usage, recycling and dissolution phases with its bio-soluble structure.

ElifCare is an environmentally friendly-patented product, prevents waste of food delivering an outstanding performance in the matter of food protection and also provides assistance in reducing ecological footprints contributing most to sustainability in production, usage, recycling and dissolution phases with its bio-soluble structure. ElifCare is suitable for common printed packaging solutions used in food, home and personal care sectors. Optical and mechanical properties of ElifCare does not differ from its non-biodegradable alternatives. ElifCare starts degrading at the end of use and, therefore, has unlimited shelf life. Elif’s new patented biodegradable material is suitable for standard test methods. ElifCare leaves no heavy metal residues in the soil and provides hygienic use for packaging of products requiring hygiene standards.