In a significant stride toward sustainable beauty, Aveda, renowned for its plant-based hair care products, has unveiled its latest innovation: globally recyclable, paper-based sample sachets. This development, achieved in collaboration with packaging partner Xela Pack, marks a departure from traditional multilayer foil sachets, aligning with Aveda's longstanding commitment to environmental responsibility.

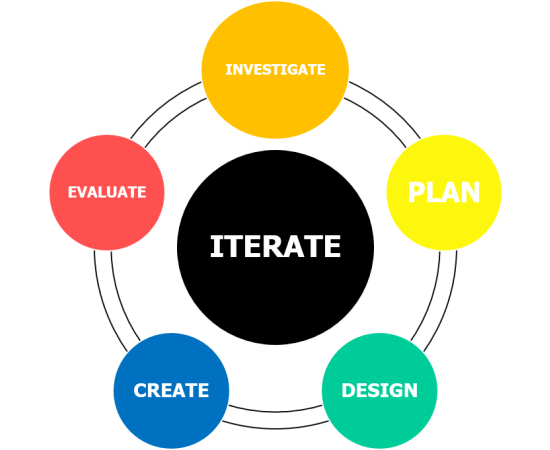

Innovative Design Meets Sustainability