Packaging affects many aspects of your products, and your business could be involved. Growth, taxation, and reduction of cost all link into the way you pack your products. So, while your company is packaging products it should consider having high standards for quality and safety.

The benefits of an efficient packaging process can positively impact the business as there are various moving parts to the packaging process. Everything included in the material brings changes while shipping your products, such as its cost, how it’s handled, and the way it looks. It also has an impact on the consumers as another packaging can be deceiving therefore challenging the consumers' psychology.

Hence, the following are tips to keep your packaging line running smoothly at peak performance.

- Keep The Line Clean

Keeping the packaging line clean doesn’t necessarily mean that it should be left spotless at the end of the day, but practicing regular cleaning is encouraged. The machines should be cleaned at the end of the shift with a pressure washer and pressurized air to remove dust.

There are two types of cleaning methods which are regular cleaning and deep cleaning. Deep cleaning needs to be done depending on the working conditions and weather. When the machine is working with corrosive materials it should be deep cleaned to prevent breakages, boost performance, improve the image of the machine, and be more effective.

You can reach out to companies that offer the best Cleaning Services to get professional and first-hand deep cleaning services.

- Train Your Employees

Today, technology is constantly evolving. Consequently, employee training is the key factor for a company’s success. The most important role of training is to ensure employees understand and safely manage the machine, therefore reducing the risk of getting injured.

Secondly, well-trained employees have better knowledge to maintain a high level of efficiency reducing the amount of machinery breakdown. All this training creates a baseline and helps to prevent troubleshooting problems. Moreover, these issues may reduce machinery performance as well as cause premature wear or machine damage. Hence, training your employees saves you hundreds of hours of repair on expensive machines. It also keeps your packaging process running smoothly.

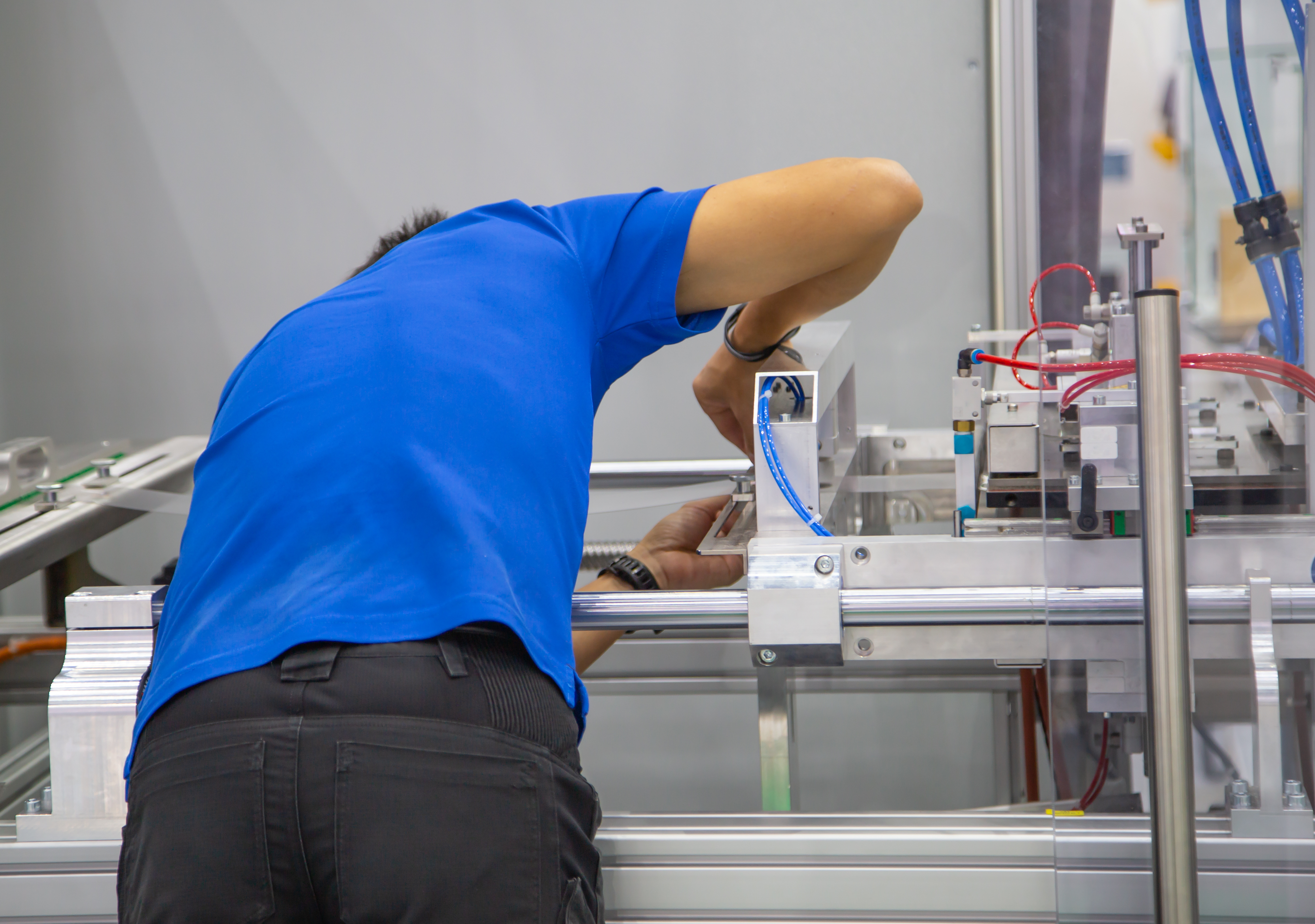

- Proper Installation And Setup

Great work performance begins with accurate installation and setup. Work with skilled vendors who are interested in their work and who want to understand your machine to make proper installation and setup. Before installing, look for quality technical experts who have experienced the same work. They must be committed to achieving your satisfaction and standards by providing the best solutions for your applications.

- Regular Maintenance

Another tip to consider is to create and adhere to a preventative schedule set to regularly check the machine. Maintenance tasks are usually conducted by qualified personnel, such as those with experienced mechanical skills. Some repairs and changes may need to be scheduled on a yearly, monthly, or even weekly basis. Although, it’s most important to adhere to the schedule.

To adhere to these schedules, you should hire a well-known company that is reliable and has experienced workers with mechanical skills. Frequently replacing wear components is designed to prevent issues in the packaging machine before it happens. The value of a well-maintained machine is it runs faster than before and doesn’t break down frequently.

- Repeatable Changeovers

To avoid the lowest possible downtime and low performance, machine changeovers need to be frequent, simple, and accurate. When you frequently do a changeover, it’ll eliminate errors and ensure accuracy, leading your business to achieve fast and accurate results. Machine adjustments also improve speed and consistency, making it a must if you want to smoothly run your packaging line.

- Keep Quality Parts In Stock

Quality parts in stock help you adhere to a regular maintenance program and prevent regular problems from happening. Keeping quality parts helps your packaging line run smoothly. This is because these parts perform better, reduce the possibility of machine damage, and last longer which saves you money and time.

- Communication

As an owner, you must encourage good communication among your service personnel and operators between shifts and any challenges they’re experiencing on the line. Communicating helps prevent downtime and faster identification of the problem with your packaging system before it worsens.

Conclusion

Maintaining your packaging line requires a commitment to ensure that the line is running smoothly. A good and well-maintained machine makes it possible for your packaging business to be successful. Also, ensure that movers clean up after every packaging to reduce congestion and mix-up. To guarantee that your business is well maintained and is running smoothly, you can follow the above guide to help you out.