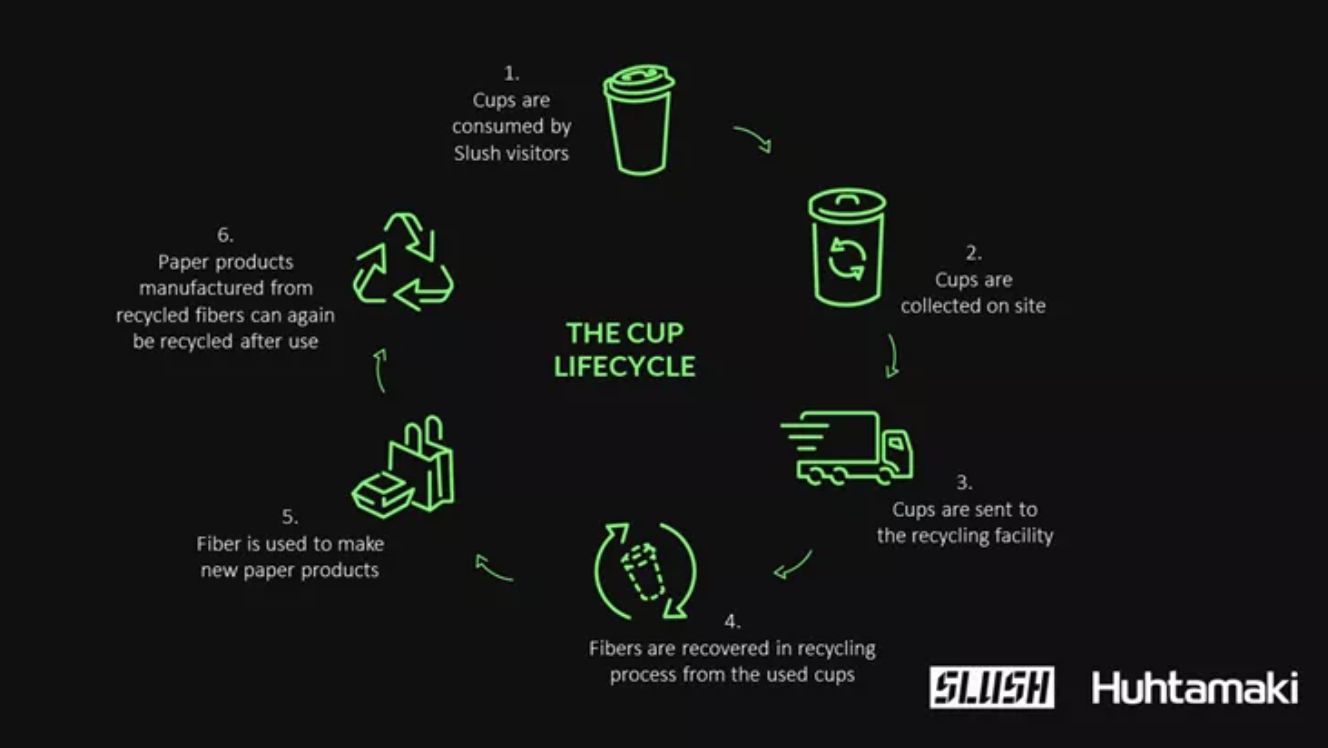

Huhtamaki and Slush have joined forces to revolutionize event sustainability by introducing a 100% closed-loop recycling system for every cup and lid used at Slush 2024. This bold move sets a new benchmark for resource management in the events sector, with all hot and cold drink cups made from recyclable fiber and collected for recycling on-site in Finland.

With sustainability at the heart of its operations, Slush has partnered with Huhtamaki to provide 13,000 attendees with locally produced, fiber-based cups and lids made from renewable certified materials. The duo aims to achieve complete recycling by deploying 33 dedicated collection bins around the venue, ensuring every used cup and lid is properly sorted and sent to a recycling facility in Varkaus.

At the facility, the discarded cups and lids are pulped to extract valuable fiber, which is then repurposed into sustainable packaging products like corrugated boxes and plant seedling containers. Huhtamaki’s fiber-based cups and lids can be recycled up to 25 times, significantly reducing waste and preserving resources.

“Our goal is to prove that closing the loop in collection and recycling is not only possible but practical,” said Huhtamaki’s Sustainability and Communications team member, Ahonen.

This marks the second year of collaboration between Huhtamaki and Slush. Building on their previous success, they’ve taken a step further to demonstrate actionable, real-world sustainability. The initiative reflects both organizations’ commitment to circularity and innovation.

“Through this partnership, we’re setting new standards for how events can manage waste and embrace circular solutions. We want to inspire other companies to rethink their approach to sustainability,” Ahonen added.

By making every cup count, Huhtamaki and Slush are creating a replicable model for other large-scale events. The initiative showcases how recycling systems can turn used materials into valuable resources, reinforcing the idea that nothing should be treated as disposable.

Together, Huhtamaki and Slush are not only talking about sustainability—they’re living it, proving that circular packaging solutions can scale even in high-pressure, high-volume environments.