Renowned all over the globe, Sacmi SACMI horizontal packagers now come with an incorporated patented automatic sleeve application system that can also be used with multi-pack configurations. Another perfect response to manufacturers' demand for innovative design and production process optimisation.

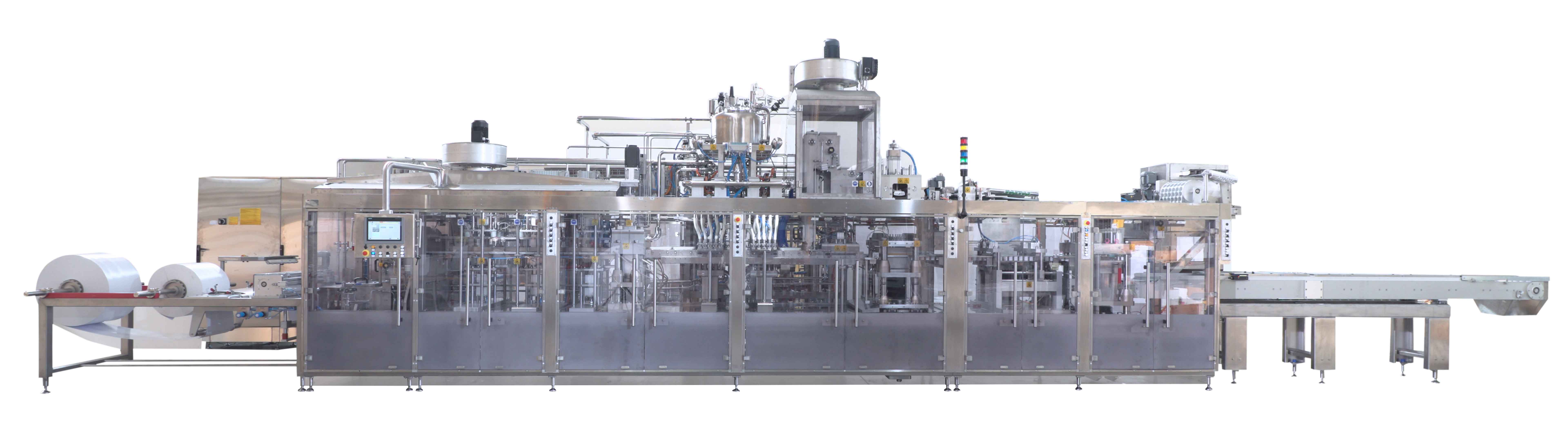

The Sacmi FFS range is set to play a leading role at Anuga FoodTec 2018 (hall 8.1 A-040/B- 049), Europe's biggest dairy packaging fair to be held in Cologne from 20 to 23 March. Developed by SACMI, with over 50 years' experience in the industry, form-fill- seal horizontal packagers for the food industry come in a wide range of configurations. Available in aseptic and non-aseptic versions, their output rates span from 6,000 to 100,000 container an hour and cover sizes from 10 to 250 ml.

More specifically, the German fair – attended by over 50,000 visitors from 140 countries – will also see Sacmi exhibit the “smart” version of the solution, a horizontal 6,000 cph packager. The version at the fair will be equipped to manufacture a standard 200 ml container of a typical Indian dairy product, the “Lassi” yoghurt drink.

Note also that the packager has been combined with the patented Sacmi ISA (Integrated Sleeve Applicator) system which applies heat-shrink labels. Thanks to a latest-generation optical recognition device, this solution can also perform decoration of multi-packs, made from a single specially printed reel of material. This system, which SACMI has integrated into the packager without in any way altering its efficiency, offers outstanding versatility and gloss printing with up to 8 colours.

The “smart” version of the FFS is part of a wide range of packaging solutions that Sacmi produces in three versions, hygienic, ultra-hygienic (ESL - extended shelf life) and aseptic. Being able to provide packagers with the Sacmi shrink sleeve application device in multi-pack configurations gives the final product added value, rewarding producers with new marketing and brand enhancement opportunities and allowing the development of new product lines at competitive cost.

Moreover, Sacmi is renowned for close customer support right from the design stage; for example, we provide consultation for the manufacture of containers with new shapes so as to achieve the best balance between eye-catching design and optimisation of raw material consumption and costs. Over the decades SACMI has reached outstanding technological heights, an achievement confirmed by numerous international acknowledgements; for example, its aseptic dairy product packaging solutions have been recognised by the US Food & Drug Administration since 1986.

One of just a handful of competitors in the world capable of developing a comprehensive range for every stage of beverage production, Sacmi's presence at this edition of Anuga FoodTec is set to reinforce its role as an all-round plant engineering supplier to the industry. The market leader in compression technology, Sacmi provides bottlers and converters with unprecedented opportunities in process synchronization, efficiency and sustainability.