Advanced tray sealing technology from Proseal is proving ideal for the safe and efficient packaging of a variety of pharmaceutical products and medical devices. Proseal’s clean-room compatible machines have replaced the time-consuming manual placement of the lidding onto the trays for a faster and more efficient continuous sealing operation that can help to reduce material usage without compromising on pack integrity.

Typical applications include medication, syringes both empty and filled, surgical instruments, surgery kits, artificial joints and implants. Proseal tray sealing machines can handle trays in many different tray designs and materials with a wide choice of sealing films, such as Tyvek ® woven material, gas barrier and UV blocking varieties.

In addition, the company’s in-house testing facility enables the trialling of different trays and films to find the best solution for individual products. This ensures that any potential tray format is conducive to sealing and able to deliver the required levels of product protection.

Tests can also be carried out to assess and quantify the peel strength of any tray and film combination. This tells users how much force is required to peel open the film – an invaluable tool in ensuring that a pack meets the required peel-ability standards that will ensure it offers the ideal balance between convenience and protection.

Proseal tray sealing machines can be tailored to the precise requirements of each application to meet the stringent quality and safety standards of the pharmaceutical and medical devices industries. Features that can be incorporated include vision systems for quality checks, production fail-safes to identify and remove ‘out of spec’ products, calibrated sensors, traceability systems and date and lot code marking.

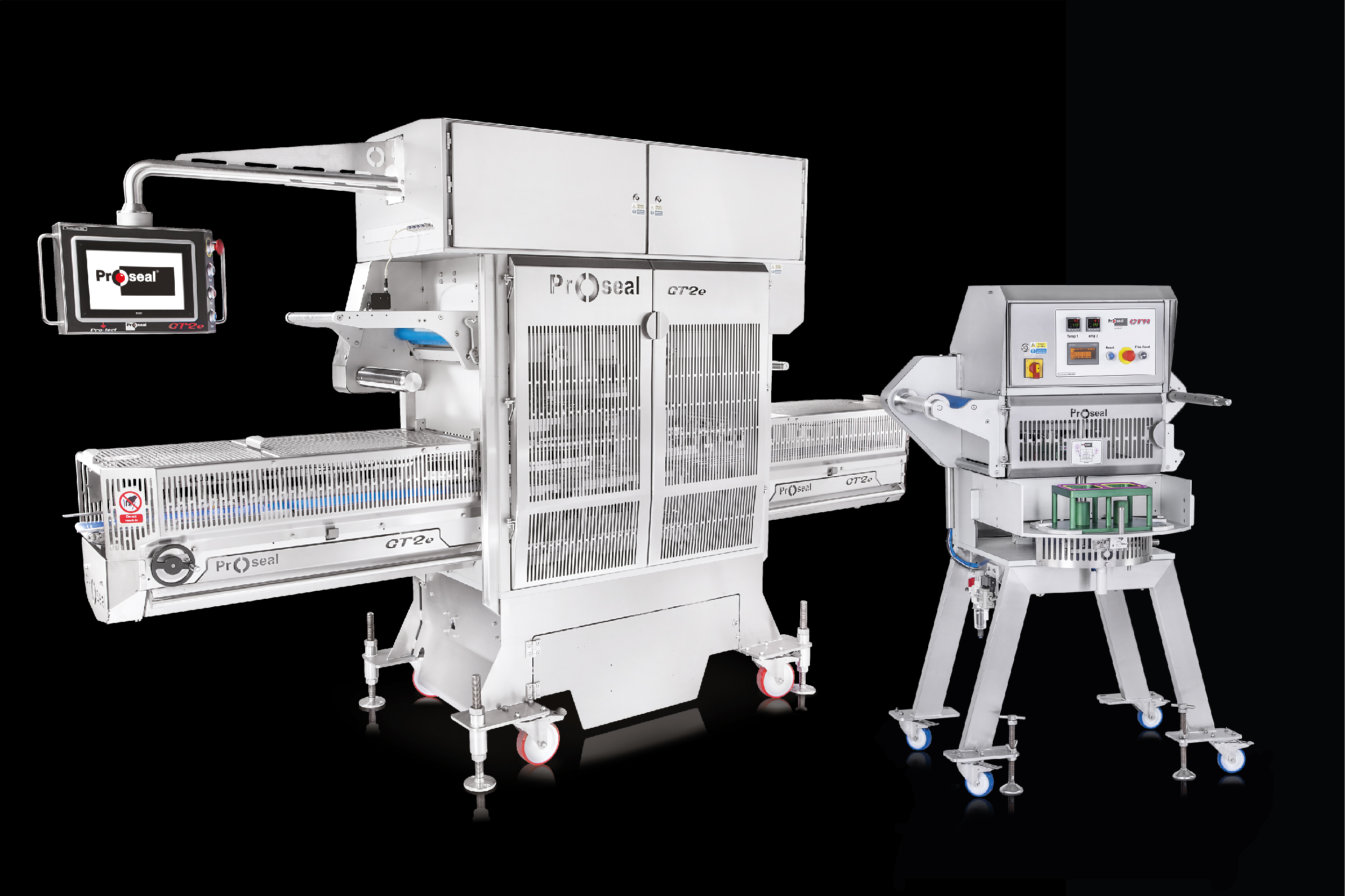

The simple and accurate film feed system and high accuracy tool alignment ensure constant accurate sealing. Consistent seal quality, strength and reliability is delivered by Proseal’s proven Eseal® technology, while the company’s unique ProPosition™ tray positioning system speeds up product changeovers and avoids operator errors during set-up. Ease of operation is further enhanced by the user-friendly menu-driven control panel with step-by-step prompts, error and status displays.

“Safe and reliable packaging is essential for any type of medical products, and a manual operation inevitably carries greater risk of operator error,” explains Simon Cheeseman, Projects Engineer at Proseal. “Our tray sealing machines are able to fully automate the sealing process, providing a faster operation and a more efficient use of materials.”

Founded in 1998, Proseal designs and manufactures high quality tray sealing machines, case packers, conveyor systems and sealing tools for markets worldwide. Proseal is part of the JBT family, and together they remain committed to continually supporting customers’ needs.