On 9 February 2019, the implementation deadline for EU Directive 2011/62 expires. The so-called Anti-Counterfeiting Directive stipulates that from then on pharmaceutical companies will only be allowed to release pharmaceuticals for trade that are subject to verification with at least two safety features. They serve to verify the authenticity of the individual packaging and provide evidence of tampering. Only after positive identification may pharmacies deliver the goods to the patient.

Such a safety feature can be achieved by special gluing of the folding boxes or their flaps. If the containers are visibly and irreparably damaged when opened, the first opening guarantee is fulfilled. Three different solution approaches have emerged for the adhesive application systems as technically feasible and suitable tamper evidence concepts: the application of non-reactive standard hotmelt based on EVA, the combined, parallel hot and cold-glue application or the use of reactive PUR hot melt adhesive.

Due to their mostly small dimensions and the resulting high production speeds, pharmaceutical packaging places special demands on adhesive application systems, especially on applicators. The production quantities require high cycle rates and very short order intervals, which standard heads of old technology often cannot achieve. In addition, their service life of 20 to 50 million cycles is too short in view of the enormous output and is only about two to four months in industrial production. Furthermore, adhesive-related soiling of the folding boxes, e.g. due to thread tension, must be avoided at all Costs.

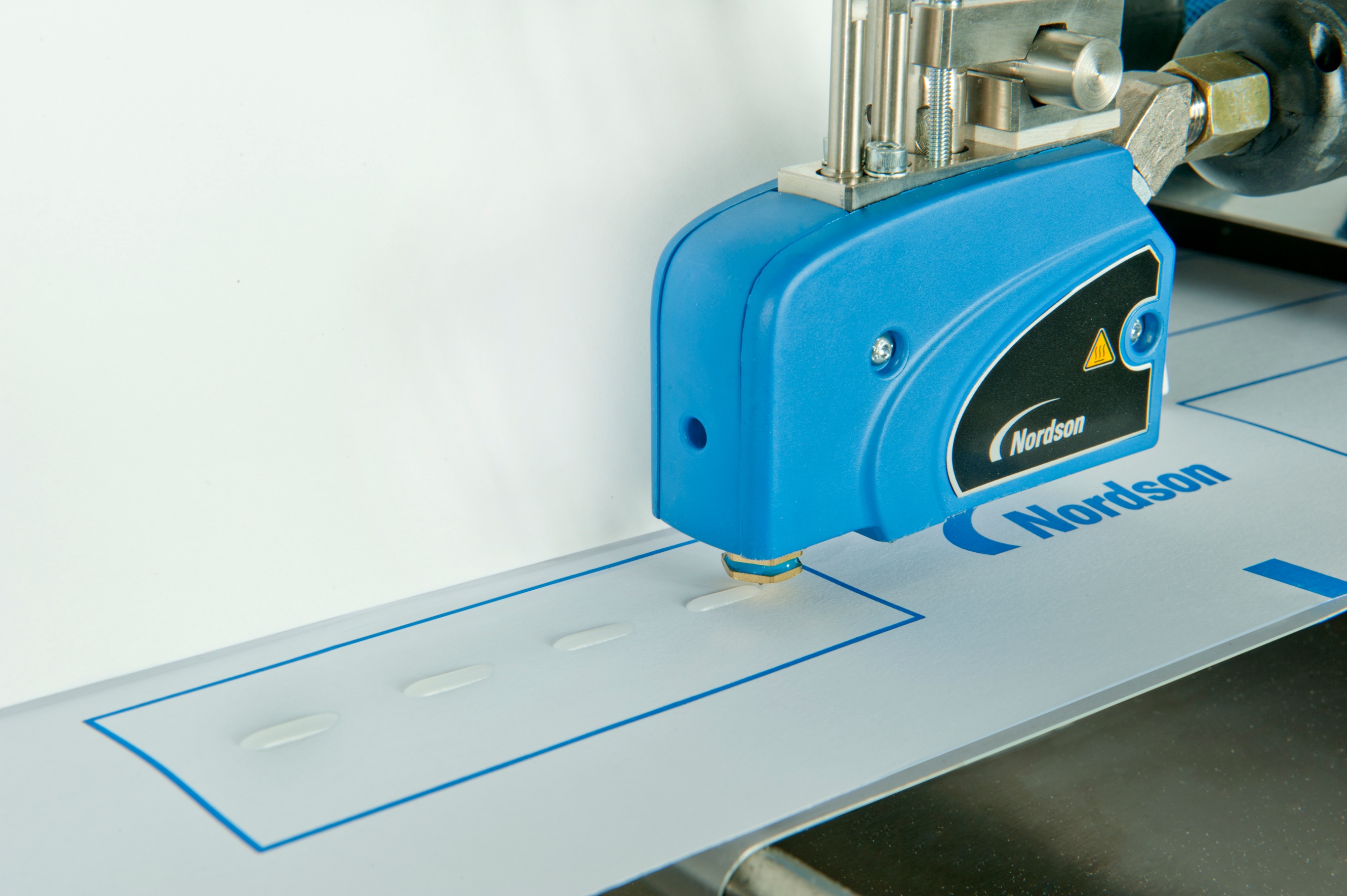

For the first hotmelt application version, only modern electric or pneumatic application heads for fast switching, short cycles and small hotmelt adhesive points can be used. Our electric applicator model edot+ and the air-opening/air-closing counterpart MiniBlue II have proven to be ideal.

The pneumatic head is selected for adhesive viscosities above 1,200 mPas to prevent contamination. The MiniBlue II achieves switching times of 2ms and guarantees a service life of over 100 million switching operations.

Ideally, hotmelts with a high softening point can be used in the pharmaceutical sector to achieve tamper evidence. Tests have shown that these bondings can only be opened with a disproportionately high effort.

Two-shot procedure

The second approach is called the two-shot procedure. This means that hotmelt and cold-glue are used together to seal the packaging. Accordingly, different applicator types are used, which are normally used for different bonding tasks. Examples are our hotmelt application head MiniBlue II and the cold-glue model LA825.

The processing method is quite efficient in terms of ensuring the first opening guarantee. The hotmelt ensures a quick hold during closure, while the dispersion adhesive has sufficient time to set. As a result, the dual bonding produced in this way can only be removed by force and not without tearing the cardboard box.

If only cold-glue were used, the disadvantage would be that the setting times are too long. This is not acceptable in production machines without long press lines. This shortcoming is eliminated by the parallel application of the smallest amount of hotmelt adhesive.

However, it should be noted that the two-shot procedure also involves problems. First of all, two application heads require more space within the packaging system. In addition, dispersion adhesives are generally more problematic to handle than hotmelt adhesives. In summary, it can be said that the described bonding method for achieving tamper evidence in the pharmaceutical sector is technically possible, but must be viewed critically due to the space and maintenance requirements.

Use of PUR hotmelt

A third possibility is the production of a tamper-evident closure using reactive PUR hotmelt. The question arises as to whether the somewhat more sensitive polyurethane hotmelt adhesive, whose processing has been an industry standard for many years, for example in the wood industry, in filter production or in bookbinderies, is optimally suited for this application.

The decision should in principle be based on the quantity required. It makes sense to use it where at least two kilograms are consumed within eight hours – under temperature load. This means that this technology should only be considered for larger production quantities.

The decisive factor is the cross-linking caused by the thermal effect and the resulting increase in the viscosity of the hotmelt adhesive. In further consideration, the use of a practically monomer-free PUR hotmelt (proportion < 0.1 %) to achieve the required isocyanate limit is particularly suitable. Laboratory tests with such adhesives, which are offered by various renowned manufacturers, have shown that a good application is achieved.

In terms of hardware, the use of electrical application heads in conjunction with reactive PUR hotmelt adhesives is ruled out due to the viscosity. The MiniBlue II pneumatic applicator proves to be ideal for this application simply because of its patented bellows seal.

Cost comparison

A cost comparison of the three approaches shows that the version with standard hotmelt is more cost-effective than the two-shot procedure and the processing of PUR hotmelt, which is by far the most expensive alternative, for relatively low production volumes, large capacities and different glue application times. The decisive factor in the latter case is above all the significantly higher cost price for the adhesive, so that the material costs per product can be twice as high or even higher.

But the classic hotmelt system is also the best choice in terms of investment costs for the necessary hardware and maintenance. When applying hotmelt and cold-glue in parallel, the two applicator heads to be used are a particular cost factor. The technical requirements for the PUR application double the procurement costs compared to the first variant. Maintenance will cause an additional load of approx. 50 percent.