The market for medical devices, in particular, implantable, is expanding rapidly as economies develop, populations get older, health awareness enhances and support policies strengthen. According to data compiled by a Chinese research network, ChinaIRN.com, the size of China's current medical equipment market has exceeded RMB 100 billion, with an average annual growth rate of about 23%, and there is a great potential for a further boom.

It becomes a major focus for medical device manufacturers to search for medical-grade high-tech materials in light of such rapid growth. With “Smart Manufacturing”, “Innovative Materials”, “Green Solutions” being the show focuses, CHINAPLAS 2018 is facilitating the formation of new trends - safety, precision, and smart manufacturing - in the medical industry, introducing high standard materials and advanced technology to the industry.

Innovative materials - help advancing to next level

Among the medical polymer materials available, plastics have the advantages of being light, tough, strongly anti-permeable, transparent and easy to mold. Compared with other raw materials such as cermets, plastics have lower costs and are safer, contributing to its increasingly extensive application. From pharmaceutical packaging to disposable medical equipment such as syringes, tubes, infusion sets and surgical instruments, plastics become ubiquitous. High-tech medical plastics is surely going to have significantly greater market shares and influence as demand in 2018 is expected to reach 6,411,700 tons.

CHI MEI CORPORATION has developed a number of high-quality plastics for the manufacturing of medical devices over the years. Besides the existing materials applied to non-invasive medical devices, recently CHI MEI CORPORATION has successfully developed even higher-quality materials with more consistent quality and better safety for use in invasive devices. The development of WONDERLITE® PC-115P is now complete. It has been verified by ISO 10993 biocompatibility testing and is suitable for sterilization using ethylene oxide (EO), gamma radiation, and E-beam. This chlorine-free, high-flowability polycarbonate is ideally suited for applications such as dialyzers and infusion parts. Visitors will see this exhibit at CHINAPLAS 2018.

TSRC Corporation announces the development of medical SEBS polymers, including VECTOR DP-8101 and VECTOR DP-8227. DP-8101 is a SEBS with median-to-high styrene content and median-to-high Mw SEBS. It passed the test for cytotoxicity and complies with GMP production. DP-8101 is suitable for general plastic modification of articles for medical application. DP-8227 is a high vinyl SEBS with median Mw and with low styrene content. It has excellent miscibility with polyolefins and can make highly transparent and much softer articles including film for medical applications.

ViviOn™ is a family of novel Cyclic Block Copolymers (CBCs), to be displayed by USI Corporation, are fully hydrogenated polymers. The flexibility of tailoring polymer micro-structure provides this advanced material a wide range of properties from rigid plastics to soft elastomers. According to its remarkable features, such as superb purity, extra-high transparency, high UV transmittance and durability, great chemical resistance, low auto-fluorescence, gamma sterilization applicable, enhanced thermo-oxidation stability, low moisture uptake, low specific gravity(0.94 g/cm³), and exceptional processability, etc. ViviOn™ can be used in optical, medical, bio-diagnostics, food packaging/infant care, and deep ultraviolet (UVC) applications.

Medical industry transforming and upgrading to smart manufacturing

The market is constantly posts new demands to medical field, such as greater product accuracy, improved core technologies, enhanced safety, higher intelligence and improved integrated innovation capabilities and manufacturing levels. Accordingly, the advancement of technology in upstream industries directly affects the technological trend of medical devices.

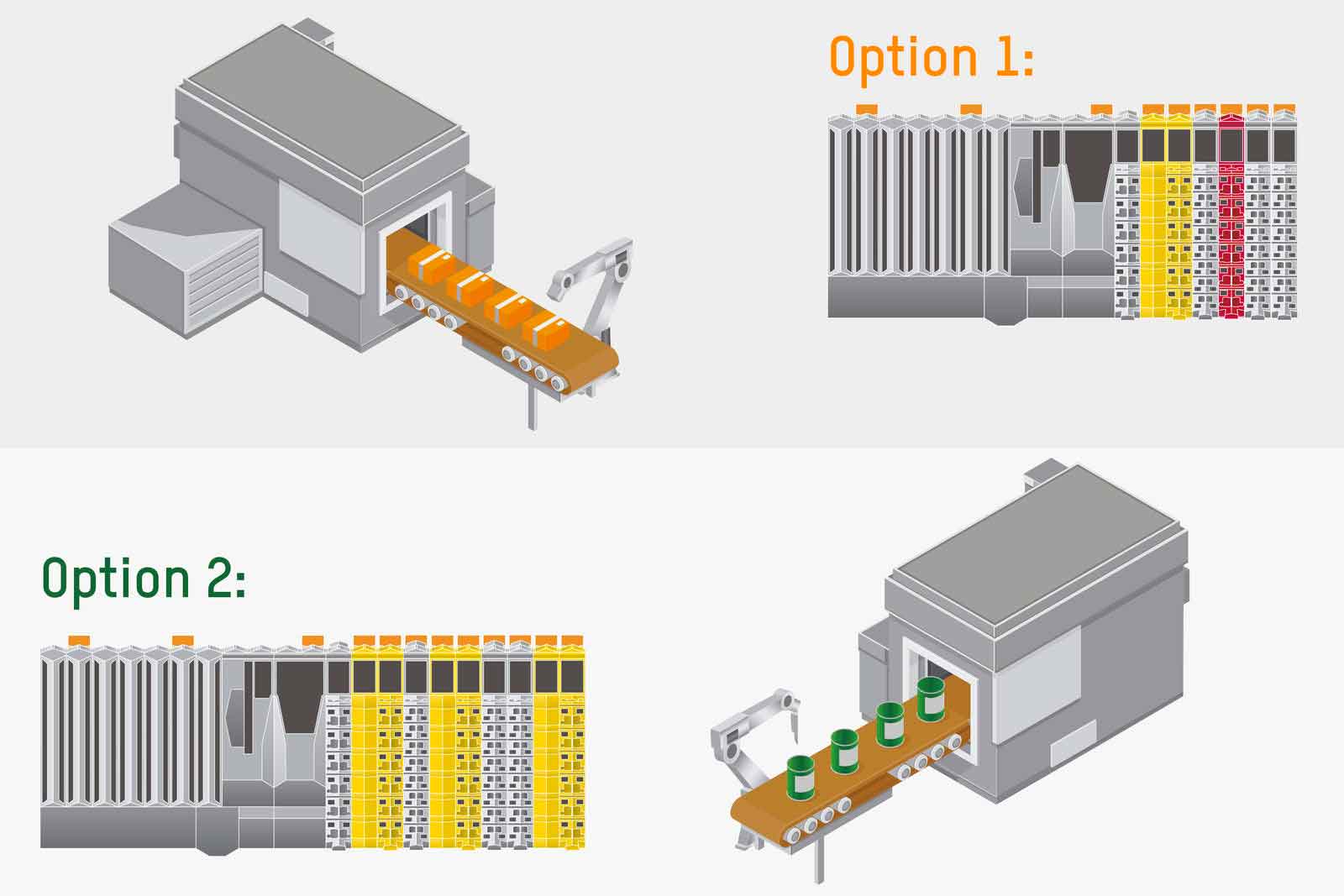

Engel Machinery (Shanghai) Co., Ltd. will launch a complete production system for manufacturing pipettes. It is a fully automated production system to manufacture pipette tips consisting of injection moulding machine, mould with 32 cavities and automation to take the pipettes out and place into pipette trays. Capacity of the production cell is more than 15,000 pipettes per hour. Main advantages of the system are clean production which is absolutely necessary for manufacturing of medical products, highest precision guaranteeing best product quality and high energy efficiency.

Medical technology requires great reliability. Haitian International Holdings Limited will bring a medical consumables clean, efficient production technology to CHINAPLAS 2018. ZHAFIR flexible clean room concepts meet the challenging requirements in terms of precision and cleanliness. From valves to syringe barrels, Haitian finds the right injection molding solution for any medical application, especially for products that require a sterile environment, the high production efficiency of our solutions can bring good economic benefits.

The new ELEKTRON, built by Milacron China, offers the advantages of all-electric injection molding technology with higher productivity and reduced power consumption in comparison to hydraulic machines. Innovation driven designs and the extensive engineering experience of Ferromatik Milacron ensure maximum uptime with economical operation. The ELEKTRON is designed for a full range of standard applications and offers outstanding value to manufactures.

More can be discovered at CHINAPLAS 2018, where more than 1,100 global exhibitors offering solutions for the medical and pharmaceutical industries will showcase their new materials, new equipment, new processes, and technologies. Among them are internationally renowned brand names such as Motan-Colortronic, Engel, Kawata, YUDO, Haitian, Fu Chun Shin, Tederic, Clariant, Solvay, Milliken, Momentive, TSRC, Lubrizol, MeHow, Mitsubishi Engineering-Plastics Corporation etc.

"Medical Plastics Connect" to present the latest solutions

In response to the compelling need of the medical industry, CHINAPLAS 2018 will launch a series of medical-related concurrent events, collectively known as “Medical Plastics Connect”, to present the latest medical plastics technologies from renowned suppliers, providing medical device, disposables and packaging manufacturers with the most advanced solutions. Activities include the “Medical Plastics Open Forum”, “Medical Plastic Product Pop-up Kiosk”, the “Medical Plastics Guidebook” and “Medical Plastics Guided Tour”.

“Medical Plastics Open Forum” will be held on 25 April 2018 from 10:30 to 13:30 in 4.2T51 (the venue of Tech Talk). At the forum, topics such as solution for Oncology IV Device, the potential use of novel Cyclic Block Copolymer (CBC) in medical applications, medical plastics application trend – TPE material development and market drive, production of diagnostics - top efficient manufacturing and automation of pipettes, Petri dishes and blood tubes etc. will be included. At the same time, global renowned medical plastics technology suppliers will give in-depth analysis from the aspects of product design, raw materials, components, manufacturing equipment, molding processes and in-field applications of products and share the latest applications of medical plastics and industry trends with manufacturers of medical device, consumables, and medical packaging. Pre-registration for the "Medical Plastics Open Forum" is now open and available at https://www.ChinaplasOnline.com/Medical18.

“Medical Plastic Product Pop-up Kiosk”- a showcase of great variety of products manufactured from the most advanced medical plastics technologies and materials - can be found at booth 5.1P39 and booth 4.2T51.

In the newly introduced “Medical Plastics Guided Tours”, visitors will be led to the booths of selected medical solution providers, so that they can meet the technical experts face to face and get the solutions they need.

“Medical Plastics Guidebook” is now downloadable from the CHINAPLAS official website for visitors to master first-hand technology news. Contents include medical plastics solution highlights, introduction of advanced technology and a list of medical plastics solution providers.

18 Theme Zones to cover all Medical Product Design and Manufacturing Industries

CHINAPLAS 2018 will take place on 24 - 27 April 2018 in a new and huge venue - National Exhibition & Convention Center (NECC), Hongqiao, Shanghai, PR China. It is anticipated that the exhibition area will reach 340,000sqm, congregating more than 4,000 leading exhibitors from 40 countries and regions. More than 120 hot and new technology will make their global or Asia launch at CHINAPLAS 2018. There will be more than 85 technical seminars. The latest plastic and rubber raw materials and more than 4,200 cutting-edge machinery and equipment will be displayed in 18 theme zones, including the 3D Technology Zone, the Thermoplastic Elastomers & Rubber Zone, the Auxiliary & Testing Equipment Zone, the Die & Mould Zone, the Smart Manufacturing Technology Zone, the Injection Molding Machinery Zone, the Plastic Packaging Machinery Zone, the Chemicals & Raw Materials Zone, the Bioplastics Zone and the Colour Pigment & Masterbatch Zone. Together, they provide full coverage of the medical product design and manufacturing industries, providing a one-stop shopping service platform for medical production enterprises.

CHINAPLAS 2018 is expected to attract more than 180,000 local and overseas professional buyers from 150 countries and regions to visit and purchase on site. Many well-known companies in the industry have already registered, including MicroPort, Tuoren Group, SHINVA, Weigao, Baxter, Hanaco, Medtronic, Shanghai Jianzhong, Jiangxi Sanxin, Jiangsu Zhognjin Medical Packing Co., Ltd., Graceheim, Terumo, Silaida, Respironics Medical Products, Dongguan Yongsheng, Shanghai Siemens Healthineers, Changzhou Kangdi, Sealed Air, and Shanghai Kindly Medical Instruments Co., Ltd.

For walk-in visitors, RMB 50 and RMB 80 will be charged for a one-day pass and a four-day pass respectively. Visitors can enjoy admission discount through online pre-registration from now till April 18, 2018, at an early-bird rate of RMB 50 for a four-day pass. To pre-register now, please visit www.ChinaplasOnline.com/prereg. For more information about CHINAPLAS 2018, please visit www.ChinaplasOnline.com.