Wolfertschwenden, 24. July 2018 – The reduction of the consumption of packaging and the use of recyclable materials in the production of packaging are currently at the top of the agenda in the packaging industry and among consumers. In the near future, the demand for recyclable packaging in particular will increase significantly. With MULTIVAC PaperBoard, MULTIVAC, as one of the leaders in the market and technology, offers a variety of solutions for the production of packaging based on paper fibre that fully meet the requirements of recyclability.

Primarily, packaging must protect the product. In respect of food, packaging substantially contributes to the improved use and prolonged shelf life. Plastic composites, which have the required barrier properties and can be easily processed on packaging machines, are predominantly used for this purpose.

The new German Packaging Act, which will come into force in 2019, and the EU Plastics Strategy, which was adopted in January 2018, are intended to counteract the massive increase in the production of plastics worldwide. The requirements essentially relate to the introduction of a recycling economy for the plastics industry and the reduction of the consumption of plastics.

At MULTIVAC, these topics are not new. "As one of the leaders in the market and technology, we continuously strive towards developing innovative machine concepts and setting new standards in the market for packaging quality and efficiency as well as the conservation of resources and the reduction of packaging. We are also convinced that the use of alternative materials will create further sustainable prospects for the future," as Valeska Haux, Vice President Corporate Marketing, explains and who is also responsible for the film business at MULTIVAC.

Alternative packaging concepts with MULTIVAC PaperBoard

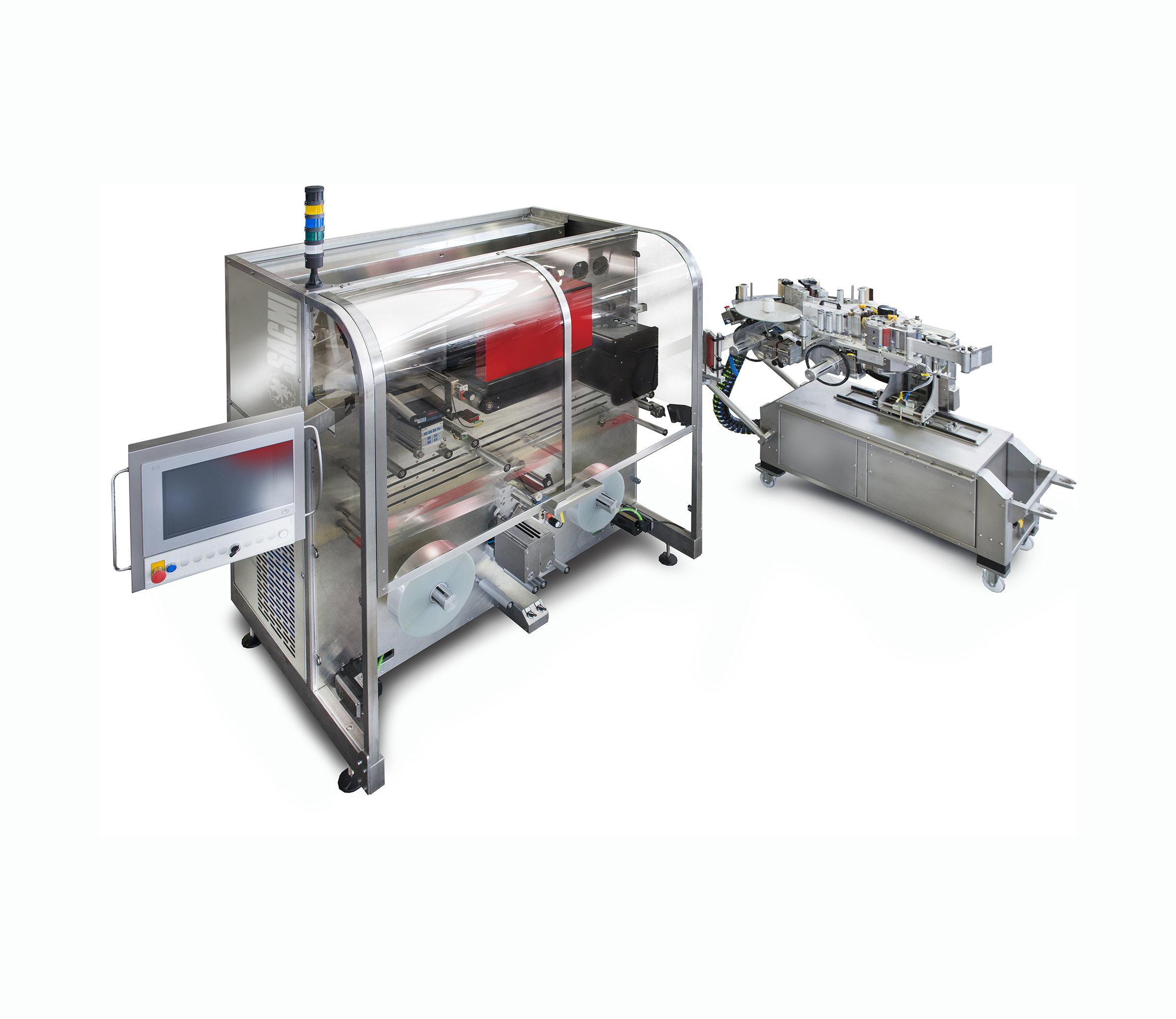

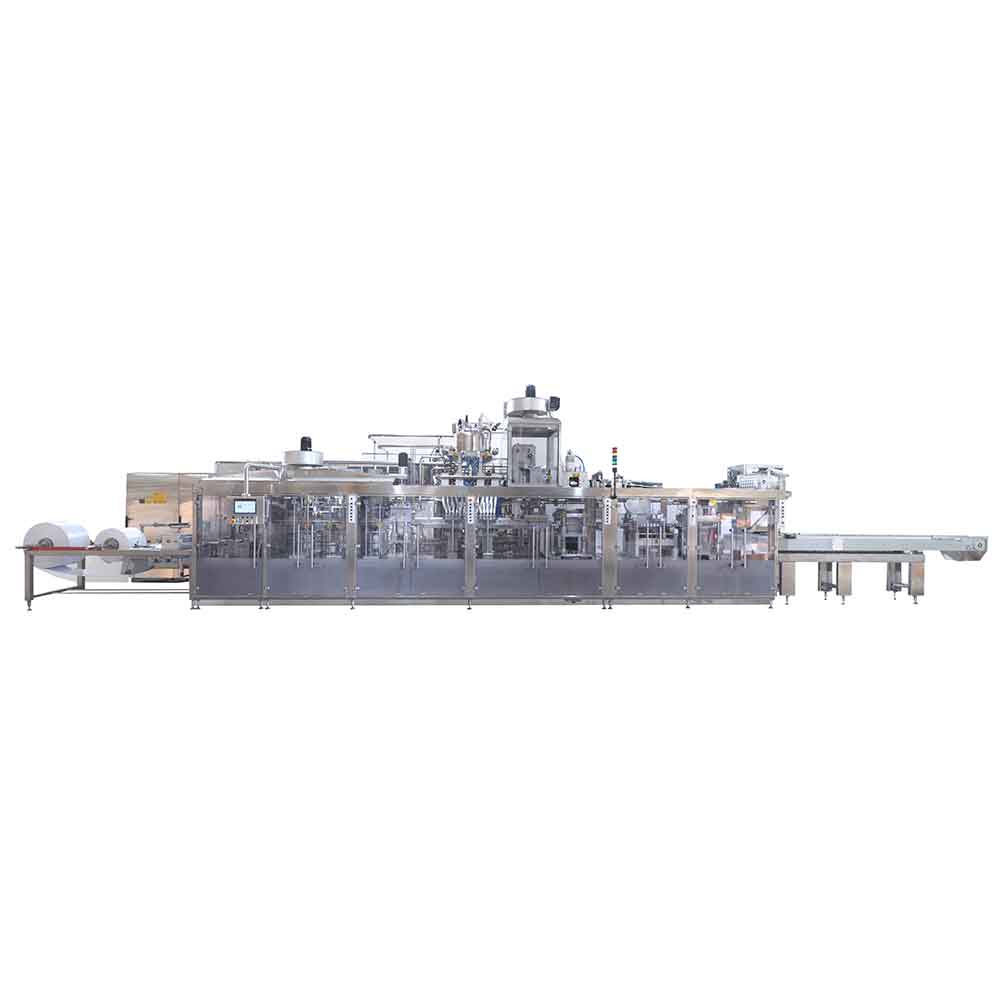

MULTIVAC PaperBoard offers various solutions for the manufacture of packaging from paper fibre based materials. In this regard, MULTIVAC works with leading manufacturers on suitable packaging materials that can be processed in standard systems. The thermoforming packagingmachines and traysealers can be individually customised for the respective performance requirements of the customers. They accordingly offer real added value in terms of package quality, output and process reliability. In addition, by means of combining infeed, outfeed and pack labelling modules, fully automated packaging solutions can be offered that fully meet the requirements in respect of efficiency.

For example, both MAP and skin packs made from paper fibre based materials can be implemented on the MULTIVAC systems. The backing material can be processed either as a roll or as a cut sheet; in addition, prefabricated trays can be used. All the materials can be separated into their respective parts by the end user and the paper backing sent for recycling.

Advantages of packaging made of fibre based materials

The use of functional layers makes it possible to produce paper-based packs that meet the barrier property requirements of plastic composites. Either the paper backing or the entire paper composite can be sent for recycling; in this regard, countries have different regulations that need to be observed.

Another advantage of paper backings is their wide design range for purposes of printing. This contributes significantly to differentiation at the point of sale. Product data can also be displayed on the paper backing so that large labels can be dispensed with.

Processing cardboard trays

For the processing of cardboard trays in MAP or skin packs, MULTIVAC offers both thermoforming packaging machines and traysealers that can be equipped with appropriate modules for the infeed and outfeed of the trays.

In contrast to the trays made of cardboard composites that are processed by the traysealer and that can be separated by type after use, the trays used for the thermoforming packaging machine are made of mono cardboard. In the thermoforming moulding die of the machine, the trays are equipped with a corresponding plastic sealing layer that can then also be separated from the cardboard after use. The output requirements of the packaging solution significantly influence the decision as to the respective ideal system.

Processing cardboard backing

Skin packs on the basis of cardboard backing can be produced with MULTIVAC thermoforming packaging machines as well as with traysealers. In contrast to the traysealer which processes cut cardboard sheets, the thermoforming packaging machine can use material from a roll, which makes this technology far more flexible in respect of the design of the packs. In addition, processing the material from a roll is also significantly more efficient.

Processing malleable paper

Similarly, MAP and skin packs made of malleable paper composites can also be produced. Paper and cardboard composites with different grammages and different functional layers are used. Pack cavities with a depth of up to 20 mm can be produced with the standard version of MULTIVAC thermoforming packaging machines. As with the previously mentioned packs, the materials of this pack can also be separated according to type and the paper backing send for recycling.

MULTIVAC expertise

In order to achieve optimal results, MULTIVAC supports its customers with comprehensive pack tests that are then used for a holistic assessment of the packs. MULTIVAC, as a system supplier, also offers suitable packaging materials that are designed for processing in packaging machines.

Our pronounced line expertise also enables the development of automatic solutions that fully meet the specific requirements of the processors in terms of output and process reliability. Initial customer projects have already been successfully completed.

In general, MULTIVAC has sufficient experience in the handling of paper-based packs – and will increasingly focus on innovative packaging concepts at future trade fairs.

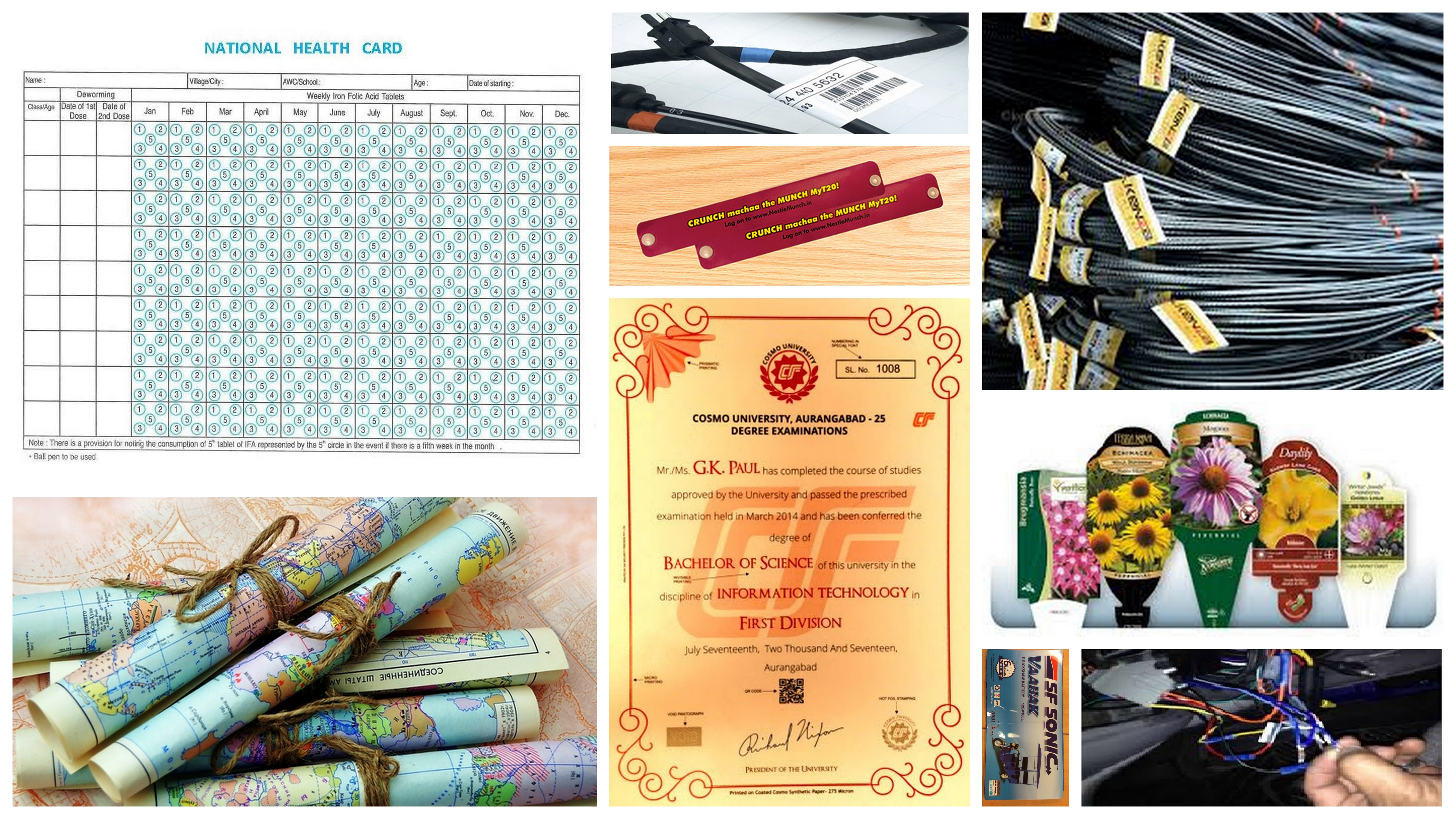

It is a replacement of paper in applications where durability and longevity is desired. It is non-tearable, has moisture and chemical resistance and excellent lay flatness. It is printable with most available printing technologies which include wet & UV offset, wet & UV flexo, letterpress, screen, thermal transfer and most of the digital toner technologies. The versatility of synthetic paper is reflected in the vast number of applications where it can be used. This includes areas such as commercial printing, tags & labels, retail & packaging, identification & credentials and outdoors. Today it is used primarily for printing visiting & ID cards, garment tags and marketing collaterals such as posters, banners etc. Going forward, all important documents like medical reports, educational certificates & land documents and instruction manuals could be printed on synthetic paper. Another important application of synthetic paper could be children & recipe books. Stationary items where longevity is essential such as maps, flip charts, and calendars could also be printed on this paper.

It is a replacement of paper in applications where durability and longevity is desired. It is non-tearable, has moisture and chemical resistance and excellent lay flatness. It is printable with most available printing technologies which include wet & UV offset, wet & UV flexo, letterpress, screen, thermal transfer and most of the digital toner technologies. The versatility of synthetic paper is reflected in the vast number of applications where it can be used. This includes areas such as commercial printing, tags & labels, retail & packaging, identification & credentials and outdoors. Today it is used primarily for printing visiting & ID cards, garment tags and marketing collaterals such as posters, banners etc. Going forward, all important documents like medical reports, educational certificates & land documents and instruction manuals could be printed on synthetic paper. Another important application of synthetic paper could be children & recipe books. Stationary items where longevity is essential such as maps, flip charts, and calendars could also be printed on this paper.