SÜDPACK and Clean Cycle Investments invest in CARBOLIQ, provider of an innovative technology for chemical recycling

SÜDPACK and Clean Cycle have signed an agreement for a long-term investment in the unique CARBOLIQ technology developed by Recenso. The decision is the logical consequence of the cooperation between SÜDPACK and CARBOLIQ that started about a year ago. Now the three companies Clean Cycle, SÜDPACK, and CARBOLIQ pool their expertise in the area of material management with chemical recycling. Their aim is to further expand available capacities for the innovative and highly efficient chemical recycling of a wide range of plastics. They plan to make currently non-reusable packaging materials suitable for recycling and for the circular economy that will be necessary in the future.

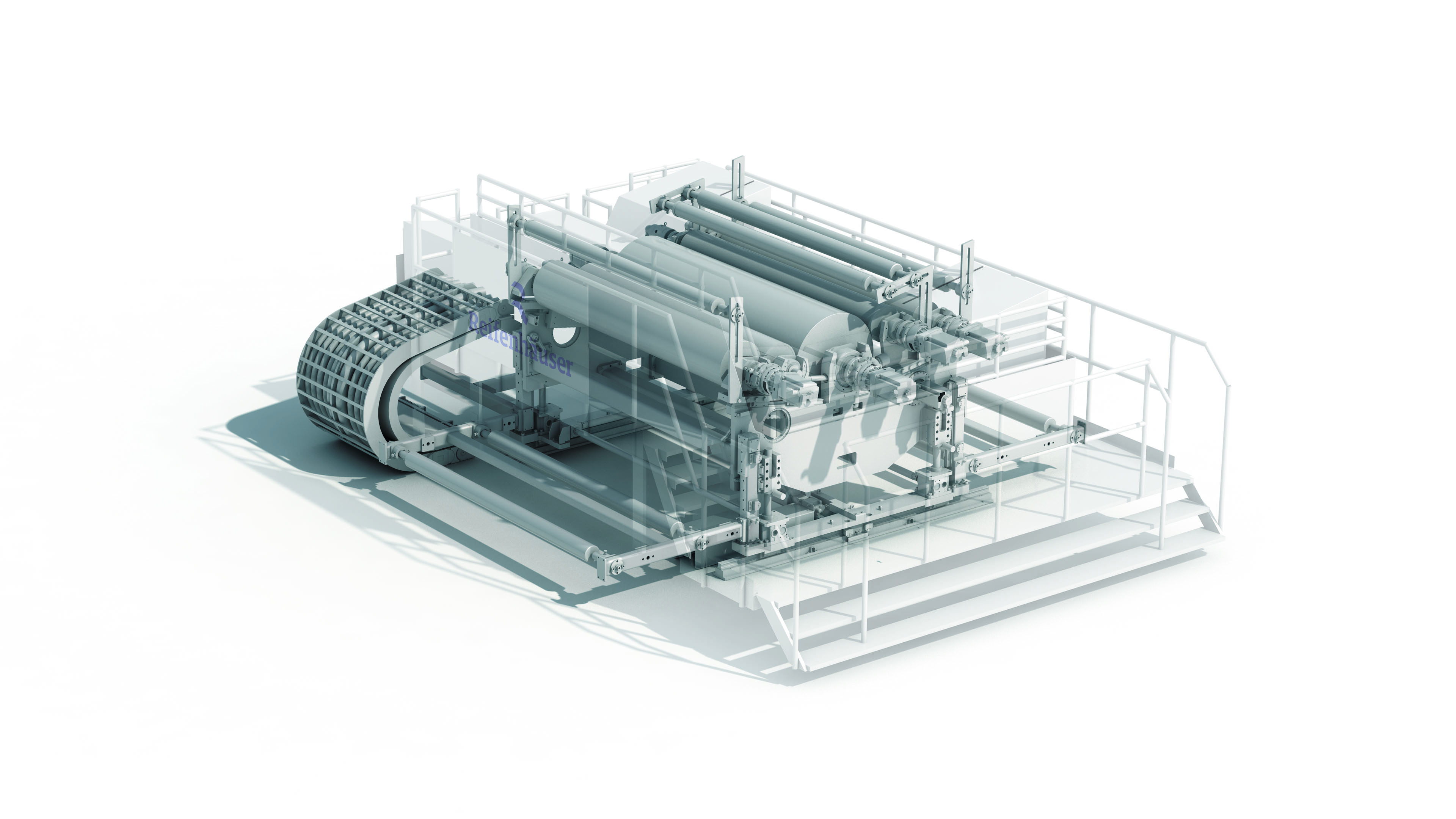

With the operation of the pilot plant at the disposal center in Ennigerloh, SÜDPACK and CARBOLIQ have proved that numerous material fractions as well as mixed and contaminated plastic wastes can be converted into a valuable resource. Apart from the large diversity of input materials, the CARBOLIQ process offers competitive advantages in terms of energy efficiency and low emissions. The oil recovered is virgin-grade quality and can be used by the plastics industry in the same way as fossil fuels to produce a wide spectrum of plastic granulates. These granulates can in turn be processed to produce high-performance films for sophisticated packaging applications which are required above all in the food industry.

So far, the cooperation partners have successfully applied the technology both for resource recovery from their own recyclable material flows as well as for recycling packaging materials from processing and from end customers. The Recenso plants for direct oiling work according to the catalytic tribochemical conversion (CTC) process and are unique in the world.

The investment in CARBOLIQ creates a powerful company that will in the medium term continually expand its capacities for highly efficient recycling of a wide variety of plastics. “Fundamentally, our joint vision is tackling the problem of high-performance flexible packaging materials that can’t be mechanically recycled with current technology. We aim to make them recyclable and therefore compatible with future needs. Thanks to the investment by SÜDPACK and Clean Cycle, we’ll be able to create a closed-loop, high-performance and industrial-standard system that also handles these products. It will allow us to exploit the extremely promising potential of our technology,” explains Christian Haupts, the CEO of CARBOLIQ.

“In a wide range of applications, for example in the food industry, high-performance multilayer films with effective protective functions are the most efficient solutions for keeping all kinds of food fresh. And they’ll remain the best choice in the future,” says Dirk Hardow, Business Unit Manager at SÜDPACK. “That’s because they provide maximum product protection at minimum added weight. However, the drawback is that they can’t be mechanically recycled. Now CARBOLIQ offers a key system component for creating a circular economy in the food packaging industry which can’t be achieved solely with mechanical recycling, also due to existing legislation. So we see our investment in CARBOLIQ as an opportunity for SÜDPACK to expand the definition of plastic waste recycling beyond just mechanical recycling.”

Similarly, Clean Cycle Investments, owned by the Last family, is committed to supporting innovations in the packaging industry that can ensure a positive future for the industry. Laurens Last explains: “We very deliberately incorporated the word ‘Cycle’ into our company’s name because we see the circular system as our top priority. We’re fully confident that chemical recycling will play a crucial role in achieving a sustainable circular economy that even includes high-performance plastic packaging. Therefore, our involvement in CARBOLIQ is not just an investment in a greener future, but also a matter close to our hearts.”

For SÜDPACK, the investment in CARBOLIQ is additionally a significant move towards the goal of a zero-waste company. The aim is zero waste not only in its own material management, but also in that of customers and stakeholders along the entire value creation chain. In addition to solutions for flexible films for the food packaging industry, CARBOLIQ also has a number of promising ideas in the fields of medical product packaging and technical applications: “So not only customers of our Business Unit Food benefit, but also customers of our Business Unit Medica and Business Unit Functional Films & Compounds. That’s because in the long term we believe it will be essential also on these markets to close cycles and permanently reduce the input of fossil raw materials,” says Johannes Remmele, entrepreneur und owner of the SÜDPACK Group.

About CARBOLIQ

CARBOLIQ GmbH is based in Remscheid and is the technology platform of RECENSO. It is responsible for the business area regeneration of hydrocarbons in waste streams. The company manufactures and operates plants for oil recovery from mixed and contaminated plastic wastes. CARBOLIQ supplies the CLR (circular liquid resource) it produces to the petrochemical industry which uses it as a substitute for fossil raw materials in the manufacture of new, high-end polymers.

About RECENSO

RECENSO GmbH is a specialist in the design and implementation of systems for resource recovery with its headquarters in Remscheid. The company provides advanced recycling solutions, thus creating the conditions for an efficient circular economy and the intelligent use of secondary raw materials. Their portfolio includes machinery and systems for both physical (mechanical) and chemical recycling based on the CARBOLIQ process. Further information: www.recenso.eu

About SÜDPACK

SÜDPACK is a leading manufacturer of high-tech films and packaging materials for the food, non-food, and medical product industries. Our solutions ensure maximum product protection as well as additional pioneering features with minimum material input.

The family business, which was founded by Alfred Remmele in 1964, is headquartered in Ochsenhausen. Production sites in Germany, France, Poland, Switzerland, the Netherlands and the USA are equipped with the latest plant technology and manufacture to the highest standards, including the capacity to operate under clean room conditions. The worldwide sales and service network ensures a high degree of proximity to the customer and comprehensive application technology support in more than 70 countries.

With its state-of-the-art Development and Application Center at its headquarters in Ochsenhausen, the innovation-oriented company offers its customers an optimal platform for carrying out application tests and for developing individual and tailor-made solutions.

SÜDPACK is committed to sustainable development and fulfills its responsibility as an employer and towards society, the environment, and its customers by developing packaging solutions that are unparalleled in their efficiency and sustainability.

Further information: www.suedpack.com

About Clean Cycle Investments

Clean Cycle Investments B.V. (Cycle) has been founded by the Family Last, an entrepreneurial family active in the fields of flexible packaging and the sole owner of the Scholle IPN Group. The Scholle IPN Group is the leader in the liquid flexible packaging industry and its business activities include the extrusion of film, injection moulding of fitments and related filling equipment.

The family Last has decided to invest an initial euro 100-150 million into highly technological companies active in the recycling industry. In that respect Cycle closed its first acquisition in 2021 by acquiring an investment in Obbotec, a Netherlands (in Rotterdam) based technology provider specialised in the chemical recycling of residual plastic waste (Scholle IPN Announces Strategic Partnership With Chemical Plastic Recycler OBBOTEC | Scholle IPN).

With the acquisition of CARBOLIQ; Cycle closes its second investment in a short period of time and adds another chemical recycling technology to its investment portfolio. Cycle is very proud to be able to join the adventure of CARBOLIQ together with SÜDPACK, to further upscale the technology and in such way working towards a more sustainable and circular world.