The prestige-pak acquisition expands our...

With this latest acquisition, C-P Fle

With this latest acquisition, C-P Fle

There are many reasons why making the change to more sustainable packaging is important, but six stand out a

BevCanna will produce and distribute the full line of Tinley’s ready-to-drink, adult beverage-inspired sparkling Tinleys Classics, Canadian versions of Tinley’s Tonics, currently available in California. The line includes the Moscow Mule-inspired Tinley’s™ Tonics High Horse™, winner of First Place at California’s prestigious Emerald Cup, the world’s largest cannabis competition. BevCanna will also produce Tinley’s blue agave & lime-inspired Stone Daisy, the juniper berry & lime-inspired Juniper Sky and the blue agave, grapefruit & lime-inspired Mystic Dove. The beverages will be modified slightly for the Canadian market to reflect Canadian consumer tastes, formulations, packaging, and regulatory requirements. As in California, the award-winning beverages will be offered in 12 fl. oz bottles, each containing a micro-dose of THC to provide a light effect comparable to a single adult beverage. Made with premium botanicals and non-alcoholic flavors often found in national-brand spirits, along with non-cannabis-derived botanical terpenes blended to match the Pineapple Jack strain, the beverages are vegan and gluten-free. They’re also crafted with Vertosa cannabis emulsion technology, combined with Tinley’s unique terpene infusion methodology, which together are designed to accelerate on-set and provide a full-flower, euphoric effect reminiscent of the Pineapple Jacks sativa strain.

Tinley’s is employing BevCanna’s white-label partnership model for its Canadian production and distribution. The model allows non-licensed partners to enter the Canadian cannabis market seamlessly and in a compliant manner. Tinley’s will leverage BevCanna’s extensive experience in producing beverages at scale, as well as its Sales License partnership for distribution to provincial buying groups. Tinley’s has committed to annual MOQs (minimum order quantities) as part of this white-label agreement.

Great North Distribution will sell the Tinleys™ products throughout Canada. Great North is Canada’s first national sales broker for legalized adult-use cannabis. Established by the owners of Southern Glazer’s Wine & Spirits, the world’s preeminent distributor for beverage alcohol, Great North Distributors has reach across every province in Canada, with established relationships and expertise in working with provincially owned and operated retailers and private retailers alike.

“We’re very excited to be selected as the Canadian manufacturing partner for Tinley’s carbonated products,” said Melise Panetta, President of BevCanna. “Their award-winning products have an exceptional following with consumers internationally, and we’re eager to offer them to the Canadian market.”

The agreement with Tinley’s is BevCanna’s fourth co-manufacturing agreement, with a strong pipeline of upcoming agreements to be announced. BevCanna is now in full commercial production, with imminent delivery to provincial distribution boards, including the Ontario Cannabis store, the largest distributor of cannabis products in Canada.

“We’re very pleased to be adding another prominent white-label partner to our growing roster of leading brands,” continued Ms. Panetta. “Production with our current white-label partners is underway, and we’re confident that we’ll be able to bring Tinley’s to market quickly, while also satisfying the strong demand we’re seeing for additional full-service, white-label beverage manufacturing services.”

“BevCanna has state of the art equipment that can uniquely accommodate the requirements of our complex formulation methodology and formats,” said Ted Zittell, director of Tinley’s. “We’re excited to bring our products from California back to our home country and are confident these beverages will provide new, unique and compelling cannabis beverage options for Canadian consumers.”

About BevCanna Enterprises Inc.

BevCanna Enterprises Inc. (CSE:BEV, Q:BVNNF, FSE:7BC) is a diversified health & wellness beverage and natural products company. BevCanna develops and manufactures a range of alkaline, plant-based, and cannabinoid beverages and supplements for both in-house brands and white-label clients.

With decades of experience creating, manufacturing, and distributing iconic brands that resonate with consumers on a global scale, the team demonstrates an expertise unmatched in the nutraceutical and cannabis-infused beverage categories. Based in British Columbia, Canada, BevCanna owns a pristine alkaline spring water aquifer and a world–class 40,000–square–foot, HACCP certified manufacturing facility, with a bottling capacity of up to 210M bottles annually. BevCanna’s extensive distribution network includes more than 3,000 points of retail distribution through its market-leading TRACE brand, its Pure Therapy natural health and wellness e-commerce platform, its fully licensed Canadian cannabis manufacturing and distribution network, and a partnership with #1 U.S. cannabis beverage company Keef Brands.

Leading technology retailer launches first-ever nationwide polystyrene store take back initiative following successful trial

Dixons Carphone is the largest retail recycler of e-waste and a major recycler of polystyrene in the UK

Company’s intention is to make 100% of its own label packaging reusable or recyclable by 2023

Published inaugural Product Packaging Guidance to share best practice on the reduction of plastic packaging across the industry

Industry first customer EPS recycling scheme

Dixons Carphone, the business behind Currys PC World, has launched an industry first recycling scheme enabling customers to return expanded polystyrene (EPS) packaging to stores for recycling for free.

After a successful trial in 14 stores over a six weeks period this summer Currys PC World is rolling out the customer EPS drop-off service to all UK stores. To begin with stores will only accept EPS associated with TV packaging but the retailer will look to collect different types of EPS packaging as consumer demand and uptake increases.

This unique service will reduce the business’ carbon footprint by extending the material’s lifecycle and, as polystyrene is made from petroleum, puts less pressure on limited resources. EPS is also notoriously awkward to dispose of at home due to its volume and is very rarely recycled by local authorities with most being incinerated or ending up in landfill.

This new in-store scheme complements Currys PC World’s existing home delivery recycling service which has allowed customers to hand back their packaging to delivery drivers for over a decade1. The retailer currently recycles over a tenth of all consumer product packing polystyrene in the UK and, working with a third party2, turns compacted EPS into insulation panels for housing.

Chris Brown, Dixons Carphone, Senior Sustainability Operations and Compliance Manager, says: “We’re proud to be the first retailer to enable customers to drop off their TV packaging in stores for recycling. Now customers can have their polystyrene taken away at delivery or drop it off at one of our stores. Whatever they choose we’ll take it off their hands and ensure we reuse or recycle it in a responsible way – helping customers do their bit for the planet.”

Recyclable Packaging Ambitions

And the business isn’t stopping there. It has also recently shared its intention to make 100% of its own label products packaging reusable or recyclable by 2023.

The retailer is working closely with its own label suppliers to help develop innovative packaging solutions without plastic or EPS. Current initiatives include the trial of switching from EPS to cardboard packaging for large domestic appliances. Other initiatives include swapping polyethylene terephthalate (PET) plastic blister trays for paper trays, changing EPS for cardboard pulp and removing single use items such as cable ties and plug pin covers.

As a result over the last year the company removed 1.7million items of plastic packaging from its own brands, over 27 tonnes, which is the equivalent weight of over 400 washing machines. Since the start of the initiative in 2019 the company has removed nearly 3m pieces of plastic packaging. Resulting in achievements such as a completely plastic packaging free brand, ADX Gaming, a key milestone towards it 2023 target.

Product Packaging Guidance for the Retail Sector

Furthermore, Dixons Carphone has created and published its Product Packaging Guidance to share best practice with the wider industry.

The guide outlines to suppliers and other retailers preferred materials to use and which materials to avoid. The company reviewed data from sources including Waste& resource Action Programme (WRAP), the British Plastics Confederation, Government Recycling regulations and the UK Plastic Pact. Teams also engaged with specialist experts to ensure the Guidance considers today’s recycling limitations as well as future plans for materials that are currently difficult or unable to be recycled.

These latest sustainability moves are underpinned by the retailer’s longstanding commitment to recycling and its accolade of being the UK’s largest retail e-waste recycler. Customers have been able to bring any electronic item to a Currys PC World store, regardless of where it has been purchased, to be recycled for over a decade.

Moira Thomas, Group Director of Sustainability and ESG, Dixons Carphone, says: “We recognise the pressing need to improve our use of resources. We are a leader in extending the life of technology through repair, recycling and reuse and we offer customers products that help them save energy, reduce waste and save water. This EPS recycling scheme and our intention to make 100% of our own label plastic packaging reusable or recyclable by 2023 is a great example of the innovative work we do to reduce our impact on the environment. We are also pleased to share that work with our suppliers and other retailers in our Product Packaging Guidance as we all work together to reduce the energy and resources used by our industry’s operations and become more sustainable.”

About Dixons Carphone

Dixons Carphone plc is a leading omnichannel retailer of technology products and services, operating through 829 stores and 16 websites in 7 countries. We Help Everyone Enjoy Amazing Technology, however they choose to shop with us.

We are the market leader in the UK & Ireland, throughout the Nordics and in Greece, employing 35,000 capable and committed colleagues across the Group. Our full range of services and support makes it easy for our customers to discover, choose, afford and enjoy the right technology for them, throughout their lives. The Group’s operations are supported by a sourcing office in Hong Kong, state-of-the-art repair facilities and an extensive distribution network, enabling delivery to stores and homes.

Our brands include Currys PC World the UK & Ireland and Carphone Warehouse and iD Mobile in the UK where our services are provided through Team Knowhow; Elkjøp, Elgiganten and Gigantti in the Nordics; and Kotsovolos in Greece.

Stora Enso and Vogue Scandinavia have won the Red Dot Design Award for the renewable eco-package concept created to replace plastics in magazine packaging. The packaging is fully carbon neutral, with a renewable, low-carbon raw material and energy efficient production. The first issue of Vogue Scandinavia was launched in August.

The Red Dot Award was granted for exceptional design quality and creative performance in the category of Brands & Communication design. With roughly 20 000 submissions, the Red Dot Award is one of the biggest design competitions in the world.

The winning packaging comes in two versions – Normal Edition and Collectors’ Item Limited Edition, both made from EnsocoatTM by Stora Enso. All materials are fiber-based and renewable, reflecting Vogue Scandinavia's commitment to sustainability. The package replaces the traditional single-use plastic wrapping used in magazines. The limited-edition packages are rigid boxes with matching artwork and debossing, inspired by Swedish artist Hilma af Klint. The magazine and its packaging are designed to be saved and kept in readers’ bookshelves. The accompanying bookmark encourages readers to read the magazine again and again.

“I am particularly pleased that the Red Dot Award: Brands & Communication Design honoured projects that address current challenges,” said Prof. Dr. Peter Zec, founder and CEO of Red Dot. “It is great that Stora Enso and Vogue Scandinavia have taken a clear position, assumed responsibility and are raising global awareness of the challenges we face today. Thanks to the outstanding quality of its design, the project conveys a clear message that can change attitudes and make people think differently.”

In 2021, designers, agencies and companies from around the world registered their creative projects and brands for the Red Dot Award: Brands & Communication Design. True to the competition’s guiding principle “In search of good design and creativity”, the 24 international jury members expertly, individually and comprehensively assessed each of the submitted communication projects and brands.

“Vogue Scandinavia was launched to disrupt the media landscape in the Nordics and to lead the way in sustainability. We want to take the next step in the future and modernize the whole concept of how magazine journalism is not only read, but done and experienced by the consumer,” said Martina Bonnier, Editor in Chief for Vogue Scandinavia. “Stora Enso is the perfect partner to do this with - they are the true innovators in carbon neutral packaging design.”

“Vogue Scandinavia is a true inspiration for us as they push the boundaries in everything they do. Their ambitions combined with our expertise in packaging design and sustainability, help move the needle towards a greener fashion industry,” said David Ekberg, EVP Packaging Solutions at Stora Enso.

About the Red Dot Awards

The Red Dot Design Award is one of the biggest design competitions in the world. In three disciplines, participants submit products, communication projects and brands as well as prototypes and concepts. The distinction “Red Dot” is an internationally recognised seal of excellent design. The award winners are presented in Red Dot’s yearbooks and museums as well as on the Red Dot website. Additional information can be found at www.red-dot.org.

Packaging engineering students across the USA will benefit from the latest technology in their studies after the latest multi-million-dollar in-kind donation from Esko underlined its continued commitment to supporting future generations of packaging industry workers.

The raft of new software upgrades and education partner license renewals will ensure that college and university students across the U.S benefit from the latest, state-of-the-art solutions from Esko, giving them first-hand experience of the technology that they will be using in the ‘real world’ after completing their studies.

Melissa Plemen, Esko Sr. Director of Inside Sales and Marketing, said the company was thrilled to continue supporting the education of the next generation of packaging employees with the donation. “As a company we invest heavily in developing new technology to streamline and simplify the packaging design and production process,” said Melissa. “We believe it is just as important to also invest in those who represent the future of our industry. We have supported schools across the country in this way for a number of years now and we are delighted to again continue that support with this latest significant donation in kind.”

Esko, the global developer of integrated software and hardware solutions for the packaging and label sectors, announced this latest investment ahead of the commencement of the new school year. Among the more-than-30 schools utilizing Esko software are Appalachian State University, Clemson University, Cal Polytech State, Dunwoody College of Technology, Eastern Washington University, Illinois State, Indiana State University, Michigan State University, Rochester Institute of Technology, Ryerson University, University of Wisconsin – Stout, and Virginia Tech.

“We’re thrilled to be extending our relationship with some of the most prestigious schools training in this hugely important field,” added Melissa. “As technological advances lead to changes within the sector, we believe it’s vitally important that the industry supports the education and training of young people as we drive to develop and inspire the packaging experts of the future.

The last 12 months alone has seen huge leaps in technology, with cloud-based solutions and Software as a Service deployment revolutionizing how many prepress departments operate,” said Melissa. “Similarly, new versions of tools such as the latest Automation Engine are supercharging Variable Date Printing possibilities, making possible concepts that had previously been simply unimaginable. Our commitment ensures today’s students are familiar with all these latest Esko solutions that are utilized around the world to manage packaging and print processes, enabling them to be truly ready for work and have the skills required to enter the sector,” she said.

With the latest donation, packaging course tutors can now use the same software that develops 9 out of 10 retail packs for major brands today and the breadth of software available enables them to teach a wide range of skillsets. Students will be able to design and create packaging from ideation through to virtual and physical prototypes, preparing them for future roles in what is a diverse and fast-paced industry.

“Throughout the last 18 months, we have seen how the global pandemic has underlined the important role technology already plays in keeping the packaging supply chain moving,” said Melissa. “As the future of the industry will inevitably involve further digitization, automation and connectivity, it is crucial that the workforce of tomorrow is as skilled and knowledgeable as possible before they embark on their career.

“We see this donation as part of our contribution to ensuring that vision becomes a reality, investing in not just the future of these young students, but also of our industry as a whole.”

To find out more about Esko technology solutions, please visit www.esko.com

Environmental groups have strengthened calls for thorough regulatory review of per- and polyfluoroalkyl substances (P

• New robotics pick-and-place platform RPP on show live for the first time

• Two automated lines for cookie and cracker packaging underline innovation potential

• Live demonstrations include virtual live launch of new LFS filling machine

• Smart service concepts and digital solutions

Syntegon Technology presents its latest processing and packaging solutions at PACK EXPO in Las Vegas from September 27 to 29, 2021. The focus of booth C-2800 is on intelligent robotics and automation technologies. Two automated lines and a series of live presentations offer visitors insights into Syntegon’s equipment and service portfolio for the factory of the future.

Robotic solutions enhance flexibility, efficiency and quality The Covid-19 pandemic has further fueled the automation megatrend. While Syntegon has been offering robotic solutions for decades, the newly developed pick-and-place platform, Syntegon RPP, sets new standards in the automation of packaging lines. The modular and highly flexible platform automates process steps such as handling, feeding, and loading for a wide range of products. Together with transport modules, the Delta robots can be flexibly connected and seamlessly integrated into an overall system

With the Sigpack TTMD topload cartoner with integrated Delta robots, Syntegon showcases another solution for automated secondary packaging. The TTMD is equipped with one or more Delta robot cells. It processes products from mulitple infeed sources in random order and orientation. A camera-based vision system detects the individual products on the infeed belt. Robotic arms pick the products and place them flat or on-edge in the cartons.

Additionally, the Kliklok ACE offers food manufacturers full flexibility in carton forming. They can choose between glue, lock-style or an innovative ultrasonic technology. Both the lock-style and ultrasonic versions are glue-free, making them a sustainable option for different carton format sizes. At PACK EXPO, visitors can experience the sustainability and efficiency benefits of the Kliklok ACE live – and take a closer look at sample trays made from paper that can replace commonly used plastic trays for cookies.

Line competence at a glance

Two automated lines provide a live overview of Syntegon’s line competence. The first line features the newly developed robotic pick and place platform RPP. The RPP Delta Robots load cookies into the infeed chain of the Pack 403 HE horizontal flow wrapper, which is specifically designed for a harsh environment and high production volumes.The flow-wrapped cookies are then packed into cartons on the Kliklok ITC integrated topload cartoner.

The second line demonstrates Syntegon’s international footprint: all technologies come from different sites and can be seamlessly integrated into one comprehensive bag-inbox line for crackers: the SVE 3822 vertical bagger feeds the crackers into a Kliklok MEC endload cartoner using the bag in box interceptor infeed with continous motion. A virtual display shows how the line can additionally be equipped with an Elematic case packer that is known for its pack style flexibility as well as tool-less and quick format changeovers.

Meet the experts live

In addition to the exhibited technologies, visitors to the booth can attend Syntegon’s live presentations. Robotics experts give detailed insights into the benefits of automated solutions, such as the Syntegon RPP pick-and-place platform or the Sigpack TTMD cartoner.

PACK EXPO also marks the virtual launch of Syntegon’s latest liquid filling machine: the LFS, which is available in clean and ultra-clean hygienic executions, fills and packages liquid and viscous food. Thanks to the new modular concept, manufacturers are able to react quickly to changing market demands and enhance their production.

Syntegon also presents an innovation for the pharmaceutical industry: with the flexible filling platform Versynta FFP, Syntegon offers pharmaceutical manufacturers, R&D laboratories, and biotech startups a standardized, modular small batch solution to safely fill liquid pharmaceuticals. Syntegon experts will be available to discuss solutions for both liquid and solid dosage forms at the booth

Tailored services and digital solutions to meet customers’ needs

All live presentations include corresponding service offers as well as a presentation of digital solutions. Syntegon’s comprehensive consulting and service portfolio along the entire machine lifecycle is tailored to specific customer needs. Remote Service is just one example to receive real-time assistance for fast and efficient support.

Syntegon’s digital solutions are designed to monitor and increase effectiveness in operations and maintenance on the shopfloor. For instance, a live presentation shows that the system not only displays machine performance data but also detects and tracks events. As of November, all Syntegon machines will be delivered “IoT ready” and provide interfaces for numerous digital solutions. Customers benefit from a holistic concept for generating, processing and analyzing machine data, entering a new level of digitalization.

Learn more about Syntegon’s robotics and automation solutions and meet the experts at PACK EXPO in Las Vegas (Central Hall, C-2800) from September 27 to 29, 2021

About Syntegon Technology Syntegon Technology is a leading global process and packaging technology provider. Formerly the packaging division of the Bosch Group, the company, headquartered in Waiblingen (Germany), has been offering complete solutions for the pharmaceutical and food industries for over 50 years. About 6,000 employees at 30 locations in more than 15 countries generated a total revenue of 1.3 billion euros in 2020. The portfolio of intelligent and sustainable technologies includes stand-alone machines, as well as complete systems and services. Fields of application in the pharmaceutical industry are the production, processing, filling, inspection and packaging of liquid and solid pharmaceuticals (e.g. syringes and capsules). In the food industry, the portfolio includes process technology for confectionery as well as packaging solutions for dry foods (e.g. bars, bakery products and coffee), frozen foods and dairy products. www.syntegon.com

DOM-TITAN is the leading Slovenian company in the field of mechanical security protection of doors and locks for furn

Our Chicopee brand’s Quix pretreated towels are helping to fulfill this need in the marketplace.

Coca-Cola HBC’s larger multipacks (10, 12, 20 and 24 cans) are now available in a new fully enclosed carton.

• Developed in collaboration with leading healthcare company

• Ideal for combination healthcare products, such as devices with an Active Pharmaceutical Ingredient

• Technology leverages Amcor’s best-in-class innovation and R&D capabilities

Amcor, a global leader in developing and producing a diverse offering of responsible packaging solutions, today announced the launch of a proprietary healthcare lidding technology that will be utilized for combination products – those consisting of two or more regulated components (device, drug or biologic).

This latest innovation from Amcor is based on a patented inert film development and laminate design. It provides a lidding solution that can withstand heat sterilization, the process of preserving and sterilizing items, while preventing drug uptake into the packaging. The packaging solution is ideal for combination healthcare products, such as devices with an Active Pharmaceutical Ingredient (API) that forms the basis of a medicine. It ensures machinability, integrity after sterilization, as well as a convenient peel opening for patients. The features of the new product complement Amcor’s existing healthcare portfolio, which range from lidding for demanding sterilization environments to high barrier overwraps protecting eye droppers and medications for the eye.

Amcor collaborated with Johnson & Johnson Vision over the course of several years to develop the lidding technology for use with contact lenses. Each company contributed specific skills and perspective, notably Amcor’s expertise with film extrusion, lamination and conversion for healthcare, and J&J Vision’s expertise on ophthalmic device packaging requirements.

Peter Konieczny, Amcor’s Chief Commercial Officer said: “We are bringing together industry-leading innovation and close customer relationships to develop the packaging solutions of the future. With this next-generation healthcare lidding technology we are opening a world of possibilities for products using active pharma ingredients. We look forward to extending this differentiated lidding technology to additional combination products in the future.”

About Amcor

Amcor is a global leader in developing and producing responsible packaging for food, beverage, pharmaceutical, medical, home- and personal-care, and other products. Amcor works with leading companies around the world to protect their products and the people who rely on them, differentiate brands, and improve supply chains through a range of flexible and rigid packaging, specialty cartons, closures, and services. The company is focused on making packaging that is increasingly light-weighted, recyclable and reusable, and made using an increasing amount of recycled content. Around 47,000 Amcor people generate US$12.5 billion in sales from operations that span about 230 locations in 40-plus countries. NYSE: AMCR; ASX: AMC

Amcor, a global leader in developing and producing a diverse offering of responsible packaging solutions, today annou

In a context of full-scale sorting and recycling infrastructure, Gualapack’s first-ever monomaterial polypropylene sp

These corrugated boxes refer to used containers or packaging made from unbleached, unwaxed paper with ruffled (‘corru

AMI, Bristol, 17/08/21 Cast PP Films – The European Market 2021, is a brand new report from leading plastics market intelligence providers, AMI. The company has leveraged its expertise and proven methodology in other consumer and industrial films, to complete this new study for 2021. The report provides critical insight and analysis of the production, capacity and demand of Cast Polypropylene (CPP) film in Europe, together with trends in key consumer and industrial applications.

Demand for Cast PP films continues to grow. The heat resistant properties of the film are invaluable to food packaging converters as well as those catering to the medical and healthcare market, sectors which have proven themselves to be Covid-19 resilient industries.

The Covid-19 pandemic also caused consumers to become more concerned with sterility and safety of their products, choosing sealed products other unpackaged, or those with loose wrapping. This stalled the “less plastic packaging” trend although this is expected to pick up as sustainability comes back to the fore.

Although Cast PP film is used worldwide, the market in Europe is of particular interest, being at the forefront of the drive to sustainability and the circular economy. Amid tightening regulations on recycling and surging media and public concern around plastic litter, companies across the plastics value chain are investigating how to mitigate this potential threat to the plastic films sector. Cast PP films can be utilised in polyolefin-based monomaterial “recycle-ready” film constructions, making it a go-to film for many packaging applications, and spurring future growth opportunities.

The study explores the variety of different properties that Cast PP films can offer the end-user, and the trends which differ by application. Each of these properties and more, is explored by end-use sector, whether in food packaging, non-food packaging or other technical applications.

New manufacturing techniques are providing further options for versatility, and many Cast PP film lines confirmed for future production are earmarked for capacity expansion or upgrading to improve speed and efficiency.

There is still a West/East divide in terms of packaging use. Cast PP production is growing in new geographic locations, which will prompt a change in trade flows.

Consumer trend analysts at Spate recently noted that the search volume for “sunscreen” has increased 30.8% year-over-

Agreement gives Aptar Pharma an exclusive 12-month option to acquire worldwide rights to Pharmaxis’ proprietary “Orbital” technology, which delivers large payloads of drug in a convenient, easy-to-use format

Crystal Lake, Illinois, August 17, 2021 - Aptar Pharma, a global leader in drug delivery systems, services and active material science solutions, today announced that they have entered into an agreement with Pharmaxis, a clinical stage drug developer, under which Aptar Pharma has the option to acquire the worldwide rights to Pharmaxis’ proprietary high payload dry powder inhaler, Orbital. As part of the agreement, Aptar Pharma will evaluate the commercial applications for the Orbital device and further develop the prototype device to meet unmet market needs. Pharmaxis retains the rights to devices containing Orbital intellectual property used to deliver inhaled mannitol.

The Orbital technology is built on Pharmaxis patents, which allow powder payloads of up to 400mg or more to be inhaled by patients in divided doses without the need to reload. This unique platform was originally developed as a life cycle extending product for the Pharmaxis cystic fibrosis drug Bronchitol®. However, it also meets an increasing global need to deliver high doses of other drugs, such as antibiotics, to the lungs.

Howard Burnett, Vice President Global Pulmonary Category, Aptar Pharma commented, “We are pleased to partner with Pharmaxis on this novel technology, which continues the development of Aptar Pharma’s industry-leading portfolio of devices for inhalation. Coupled with our broad Aptar Pharma Services offering, we will seek to expand the range of drugs administered by inhalation.”

“I am delighted with the forthcoming partnership with Aptar Pharma, who are one of the world’s foremost drug delivery device companies. In their hands, we hope to fully exploit the potential of the Orbital technology in other drugs and secure a return on the work we have already completed,” commented Pharmaxis CEO Gary Phillips. “The Orbital Inhaler is an innovative new device that eliminates the need for manual reloading of multiple powdercontaining capsules needed for a single dose of drug. This can deliver improvements in the patient experience, compliance, market share and also effectively extend patent life of drugs that use the device.”

About Pharmaxis Pharmaxis Ltd is an Australian clinical stage drug development company developing drugs for inflammatory and fibrotic diseases, with a focus on myelofibrosis. The company has a highly productive drug discovery engine built on its expertise in the chemistry of amine oxidase inhibitors, with drug candidates in clinical trials. Pharmaxis has also developed two respiratory products which are approved and supplied in global markets, generating ongoing revenue. Pharmaxis is listed on the Australian Securities Exchange (PXS). Its head office, manufacturing and research facilities are in Sydney, Australia. www.pharmaxis.com.au.

About Aptar Pharma

Aptar Pharma is part of AptarGroup, Inc., a global leader in the design and manufacturing of a broad range of drug delivery, consumer product dispensing and active material science solutions. Aptar’s innovative solutions and services serve a variety of end markets including pharmaceutical, beauty, personal care, home, food and beverage. Using insights, proprietary design, engineering and science to create dispensing, dosing and protective technologies for many of the world’s leading brands, Aptar in turn makes a meaningful difference in the lives, looks, health and homes of millions of patients and consumers around the world. Aptar is headquartered in Crystal Lake, Illinois and has 13,000 dedicated employees in 20 countries. For more information, visit www.aptar.com.

Global aerosol dispensing company, LINDAL Group has introduced an advanced spray imaging system to help deliver new levels of spray performance insight for customers.

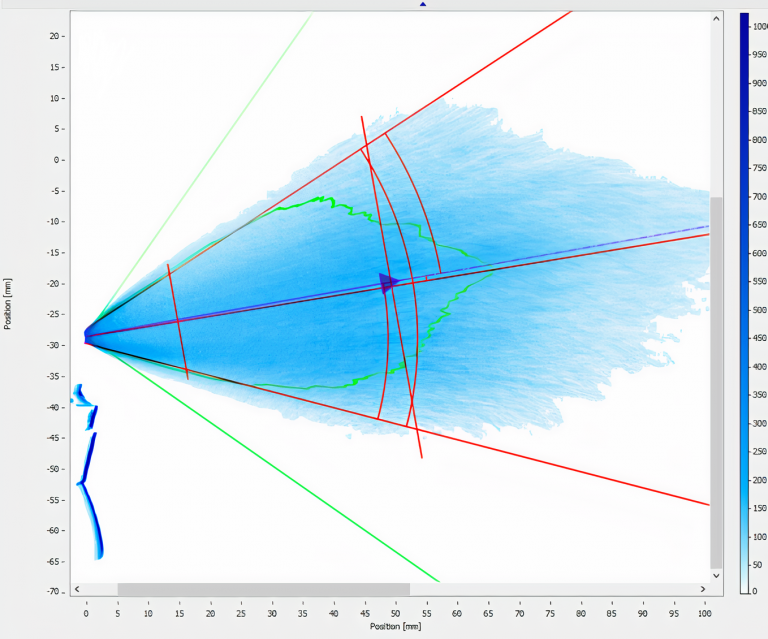

As market-leading dispensing experts, LINDAL already conduct detailed spray analysis in the form of flow, particle size, spray angle/shape and spray pattern performance on their standard product range, as well as the bespoke solutions they work on with their innovation partners. The new technology not only adds to this, but provides a new avenue for in-depth consumer tests, with additional spray characterisations, including the measurement of shape and velocity also planned for the future utilisation of the technology.

The new measurement technology, deployed at LINDAL’s Global Innovation Centre in France, uses optical techniques to capture spray behaviour at high speed (around 7500 images per second). Comprising of front and back radial lighting, camera and suction system hardware, its integrated software produces 30 second videos of spray movement for analysis, equivalent to 0.1 seconds in real time. The process provides detailed information on axial plume spray, including the particle distribution as well as the angle, diameter and length.

Eric Lambine, Central Laboratory Manager at LINDAL’s GIC, said: “The software’s ability to capture the behaviour of the spray and not simply the size of spray particles, is crucial. This information allows us to understand so much more about spray patterns and performance, which creates far greater objectivity to our analyses and discussions. We believe it will significantly benefit our customers that we are working with now and in the future.”

The company believes the spray imaging system will also be effective when testing compressed air dispensing solutions. Spray performance can be affected due to a reduction of pressure over the lifecycle of the can, resulting in a larger droplet sizes and a ‘wet’ final product, not suitable for products such as hairsprays and deodorants.

With the production of more in-depth spray performance data, LINDAL plans to use the technology with compressed air systems to greater understand the performance of the product in association with the valve and actuator combination, over the lifecycle of a can.

Eric says: “We aim to generate a template incorporating an optimum propellant, valve and actuator combination, as well as deriving further quantitative data, producing new levels of quality in all our dispensing systems. Our ultimate goal is to give our customers the best opportunity to provide an improved consumer experience.”

About LINDAL Group

LINDAL Group is a worldwide leader in the design, manufacture and sale of valves, actuators and spray caps used in aerosol products. The Hamburg, Germany-based company has more than 60 years of experience with innovative dispensing solutions for the cosmetics, household, pharmaceuticals, food and technical industries.

The LINDAL Group is represented by subsidiaries and licensees in more than 15 countries throughout Europe, Asia and The Americas. The company is renowned for its innovative designs, which deliver optimal functionality and return on investment. As a result, LINDAL packaging solutions are the choice of the world’s most prestigious and trusted brands.

For more information, please contact: marketing@lindalgroup.com.

Liquibox’s Liquipure ultra mono-material flexible packaging for bag-in-box beverages was selected for an Ameristar Packaging Award.

Launched only a few months ago, Liquipure ultra has already been a game-changer for the beverage industry. The Liquibox recycle-ready packaging uses advanced resin technology that is ultra-strong to provide reliable product protection, and yet sustainably simple, as the company calls it, to meet recyclability guidelines. This innovation replaced the non-recyclable multi-material laminates with nylon or metallized polyester that have been used for decades to protect products such as post-mix syrups, bag-in-box water and bag-in-box oils. In addition, the unique flexibility enables the solution to evacuate product at the same rate as flexible packaging with an evacuation device—but without the added plastic. Liquipure ultra stands out in the market due to the impressive performance characteristics paired with sustainability benefits that allow customers to divert tons of plastic waste from the landfill.

Liquibox is thrilled to be recognized by Ameristar for their packaging solution in the category of non-alcoholic beverages. Organized by the Institute of Packaging Professionals (IoPP), the Ameristar awards are one of the oldest and most prestigious design competitions. Learn more about the award winners here or visit the display at the Pack Expo Las Vegas Showcase of Innovations or the IoPP booth (#C-1253) and be sure to check out Liquibox’s display at booth #6131.

About Liquibox

Founded in 1961, Liquibox is a global leader in liquid packaging and dispensing—working in partnership with customers to create a safer and more sustainable future. Liquibox is committed to delivering high-quality, innovative flexible packaging solutions that offer reliable product protection. The company is inspiring change around the world, working as one across 19 global locations powered by a dedicated workforce of nearly 1,400 employees. They are headquartered in Richmond, Virginia (USA).

For more information, contact Anastasia Khodakova, Global Marketing Director, at akhodakova@liquibox.com.