My Content

-

PackMach Asia Expo, an international trade show for packaging and processing, is jointly organized by The Institute of Packaging Machinery Manufacturers of India(IPMMI), and Messe Muenchen India. It is supported by a renowned body - the PHD Chamber of Commerce International (PHDCCI) which acts as an industry partner. The PackMach Asia Expo will

-

Biodegradable expo- 2023

Biodegradable Expo is a focus three-day trade exhibition on biodegradable & sustainable products, machinery, raw materials & allied Industries where all the stakeholders for the biodegradable and sustainable packaging industry could be brought under one roof. -

Printpack india 2023

PRINTPACK INDIA is held in India Expo Centre Greater Noida from 1st to 6th February 2023 showing the companies news of India and internationals related to sectors Packaging machinery, Printing machinery, Printing, and Packaging. Date- 1st Feb to 6th Feb. 2023 -

Cii packaging summit 2023

This summit will offer an excellent opportunity to discuss, share experiences, have live case studies, network with industry leaders, and learn about the current and innovative practices in the industry to help us improve and achieve our packaging goals. -

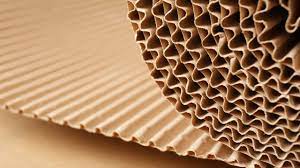

What is flute in the corrugated fibre bo...

Flute refers to the material contained between the liner boards of the carton box. The construction of the flute helps to make the carton more durable and able to withstand more pressure. It affects how easily the box dents and the height at which the boxes can be stacked for shipping.

There are variations in flutes or corrugations depending on the types of fluted rolls used. A, C, B and E are a few popular flutes that are used more than others as per their suitable applications, shown below in the table.

The Flute is determined by its size. Flute size is involved two factors: Flute Pitch, Flute Height.

Flute Pitch: It is the horizontal distance between adjacent flute troughs.

Flute Height: It is vertical through to the peak distance of the flute.

To know more about this in detail you can refer "The Big Book of Packaging"

Image

-

Candle lid & meal closure for the glass ...

The Continuous Thread aluminum closure is characterized by an uninterrupted spiraling thread.

-

Bharat biotech to roll-out intranasal co...

Hyderabad-based Bharat Biotech has announced that iNCOVACC®️ (BBV154), is scheduled to be introduced in the country a

-

Datwyler adds steam sterilization option...

Datwyler, a leading provider of high-quality, system-critical elastomer components, announces the launch of Steam Ste

-

Paper bottle revolution is coming to fra...

French wine distributor ‘Somewhere in Provence’ has invested in a new filling line and is offering contract bottling

-

Isr signs agreement with gerresheimer

The drug development company ISR (Immune System Regulation Holding AB) has signed an agreement with Gerresheimer for

-

Starbucks like every christmas , brings ...

The holiday season is creeping into Starbucks' cafés nationwide earlier than ever, as the coffee cha

-

5 things to consider when you need paper...

Did you know, in one year, 5 billion plastic bags are used around the world? Low-density plastic bags are very difficult to recycle, meaning the majority fill up landfills. Plastic bags also do not readily break down and are harmful to the planet and wildlife when they end up in the environment. As their environmental impacts are realized, plastic bags are being banned in locations all over the world. But even with legislation forcing a move away from single-use plastics, the choice to move to paper can provide other benefits.

We explore 5 questions to ask when considering making the move to paper:

1. Is the paper bag food safe?

With health and hygiene more of a priority than ever, you should ensure that your packaging products are food safe, including bags used to hold or transport food. Ask suppliers if their paper bags are manufactured in food-grade environments.

Providing a hygienic and food-contact-safe option for a variety of needs, paper bags meet high-quality standards.

2. Does the bag have the right strength profile for your needs?

With more strength than you can handle, paper bags are often stronger than their plastic equivalents, when made with quality and sustainable raw materials. Ensure you have asked your supplier about the strength profile of the bag you are considering or even test it yourself!

Strong enough for a large grocery shop through to food delivery for the whole family, paper bags can offer superior strength for a variety of needs, Must use high quality, ethically sourced kraft paper to manufacture bags.

3. Are paper bags fridge-friendly?

Not all paper bags are made equal and the material doesn’t traditionally lend itself to cold or damp environments. If you are looking to use paper bags for chilled goods, make sure they won’t fail your customers.

Manufactured with quality in mind, their bags need to be strong enough to handle condensation from grocery items, such as milk bottles. Quality paper bags are suitable for chilled environments like fridges and can handle condensation from contents without compromising performance.

4. Does your bag promote food integrity?

The permeability of a paper bag allows steam to escape, whereas it won’t work in a plastic bag. This is why chips or fried foods transported in a plastic bag tend to go soggy.

Steam can’t escape as effectively in a plastic bag, and therefore condenses on the inside of the bag. Water molecules are then reabsorbed which softens the texture of the chips or fried foods, and because water absorbs heat energy, the food will also cool down faster.

A paper bag promotes food integrity, especially if food needs to travel or be taken away.

5. Is this bag sustainable?Paper bags are made from a renewable resource, and have multiple end-of-life options. Strong enough to be reused by consumers on multiple occasions, paper bags provide flexibility in their uses.

Able to be reused, recycled, or composted, moving to a paper bag is a sustainable option.

Image

-

Woolworths backs sa manufacturing as it ...

Woolworths has partnered with South Australian manufacturer Detpak to offer customers locally-made paper bags in SA a

-

A double dose of safety: needle protecti...

-

Ez fillsmart- makes your life easier

-

Solution for excessive packaging by p&g ...

-

New dpi device for the generic drug mark...

-

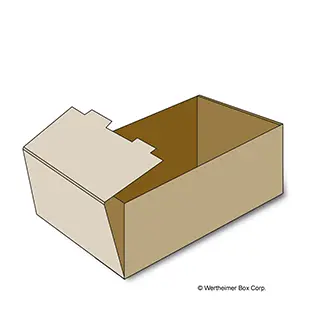

Top styles of corrugated boxes in trend ...

Corrugated Fibre Board satisfies virtually all functions of Packaging & also the environmental criteria. let's dig deep into the style of the boxes in trend.

Half-Slotted Container(HSC)- A variation of the RSC, The Half-Slotted Carton has only one set of flaps. The opposite side of the box is completely open allowing it to slide over an item. Envision the use of the box turned over so that the flaps are on the top. The covered item is usually attached to a pallet or other type of surface that serves as a separate bottom.

Regular Slotted Container(RSC)- Also called shipping boxes. RSC is the most used boxes. They are usually Kraft brown in color, have four flaps on the top and bottom. The side walls are sealed at one corner known as the Manufactures' Joint. The design is highly functional for most packing needs.

Roll end tray with Self Locking Ends

Formed from a single piece of the combined board The design features unbroken and several layers of corrugated in the end panels. Trays are not shipping containers, but they are frequently used as inner containers for parts delicate produce letter mail and other products, or as elements of display stands.

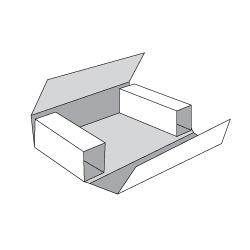

Locking Cover I Mailer Style Box (MSB)

A one-piece die-cut box that is assembled without tape. Construction includes double-layer protection on the sides and bottom of the box. Available in two popular styles - with a tuck-in top or with a locking cover, also known as a "cherry lock" design. Mailer-style Boxes are exceptionally strong and can withstand the most rigorous treatment during shipment.

Full Overlap Slotted Container (FOL)

With a full overlap Slotted Carton, all Length flaps are also equal to the width of the box. The flaps actually fold over one another to provide added strength and protection to the top and bottom.

Five Panel Folder (FPF)

A Five Panel folder actually resembles a shallow depth box when assembled. It is a one piece box with over-lapping end panels. The functional design is also economical.

One Place Folder (OPF)

Commonly called "Book folds" or Book wraps the one-piece Folder has a flat bottom with two short flaps forming the sides at each end and two longer wider flaps that form the front back and top of the box. The wider flaps either meet or overlap on the top. Depending on the depth of the contents. The four panels of a Book fold are usually scored creased) at multiple depths. One-piece folders are used to package shallow-depth items such as books and pictures. Usually manufactured with white board.

Snap Bottom Containers with RSC Top

Available with a tuck-in top or with RSC-style top flaps (shown). Also referred to as an "auto bottom" box. The bottom of the box snaps into place without tape for quick assembly Best suited for lightweight products.

Full Telescope Design Canon (FTD)

A two-place box with a separate lid that fits over a bottom tray.

One Place Folder with Air Cell/End Buffers

One piece folders also come with Inner end folds that help better protect the inside of the product from damaged corners and sides .

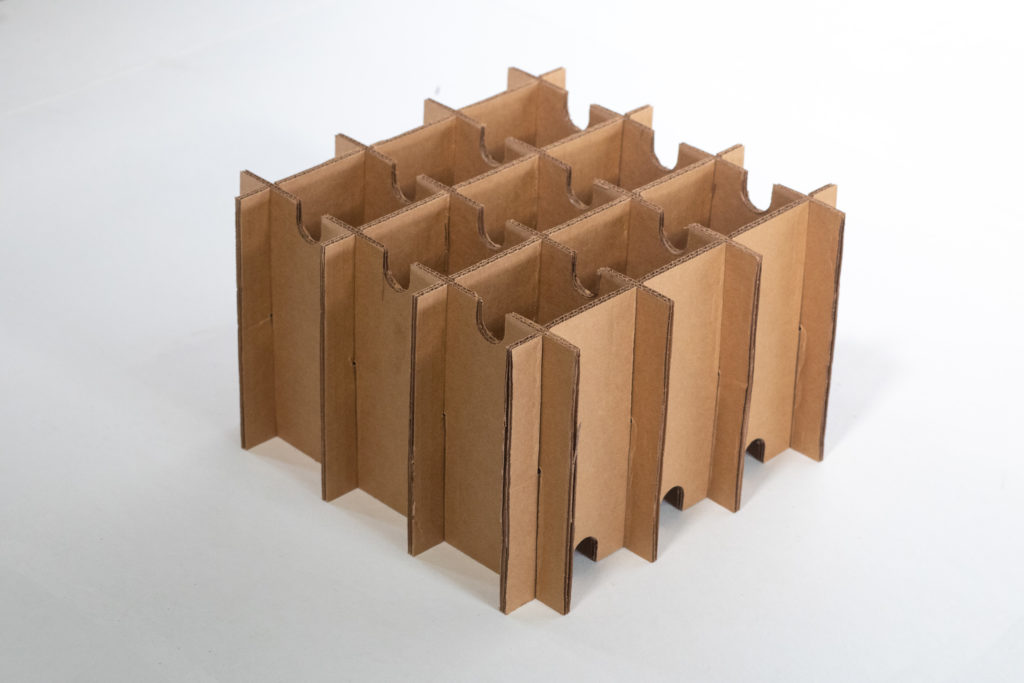

Partitions

Partitions or dividers provide a separate cell for each item in a box. They are used primarily for glassware and other fragile articles.

To know more about - Corrugated Fiber Board, Buy "The Big Book of Packaging" from https://www.bigbookofpackaging.com or from Amazon

Image

-

Solution concept for sensitive substance...

The pharmaceutical industry is increasingly using polymer syringes made of COC/COP (cyclo-olefin copolymers/cyclo-ole

-

Pioneer of corona treatment- happy birth...

On what would have been their Father’s centenary, Nick Coombes speaks with Frank and

Jan Eisby about the man who invented corona treatment

NC: Take me back to the very beginning

JE: Verner had always had an interest in things electrical. At school he and his friend Tage were building amplifiers and speakers to take to teenage parties, and this subsequently developed into ‘ship to shore’ two-way communication technology, which was a hot topic at the time. In fact, that’s where the company name comes from: ‘Ve’ from Verner, ‘Ta’ from Tage and ‘phone’ from phonics – hence Vetaphone!

NC: How did that have a relevance to the packaging industry?

FE: The years after the Second World War saw the advent of plastic materials in packaging, and brand owners were keen to have their products displayed in bright colours on this new material. This was especially true in the food industry, where the extra shelf-life that plastic packaging offered was a significant advantage. It was, I suppose, the early days of ‘best before’ and ‘sell by’ labelling that is common on food packaging today.

NC: How did Verner become involved?

JE: It was a chance meeting with a printer who was having difficulty getting the ink to adhere securely to this new plastic material without smudging on contact. He asked Verner for help, and after testing the ink and material in his small home workshop, he found that it all related to incompatible surface energy between the liquid and the solid.

NC: And this went on to become corona treatment?

FE: To cut a long story short, yes it did! Verner found that by passing an electric discharge over the plastic at close range he could change the molecular structure of the surface and improve adhesion. There is much more to that story than we can go into here, but fundamentally what he was doing back in 1951 is what we, and all other corona manufacturers, are doing today. And it all started on his work bench!

NC: What were the early days like?

JE: Chaotic! Dad was an inventor and Mum tried to manage the finances as well as bring up two boys. They worked all hours, and we travelled extensively trying to explain and convince a sceptical market that the technology really worked, even if it was difficult to explain how. Family holidays were based around a tour of potential customers and Verner spent many years visiting universities and institutes discussing his newly developed process. Frank and I saw a lot of Europe in those days, and it was a great educational experience for two youngsters.

NC: What was he like as a person?

FE: He was passionate about most things scientific – always keen to know how things worked and find ways to improve them. His interests included designing sophisticated communication systems for the Danish fishing fleet, to developing automated watering systems for greenhouses – he was a boffin! His background was electrical engineering and the transmission of power. This is what gave him the knowledge to develop a system that applied an electric discharge at close range to a potentially flammable substance – heat and plastic don’t mix well! What Verner did was learn how to control the power generation via the transformer, and 70 years on it’s what we do today but with 21st century electronics.

NC: How did he get into manufacturing?

JE: He was already manufacturing radios and two-way radios for the local fire department, so after coming up with corona treatment invention he produced them side by side. But demand for treatment systems was overwhelming, so the production of radios soon stopped. In the mid 60’s he moved the business to our current location, initially renting part of a factory but soon taking it over completely. Vetaphone was still a small company but was beginning to make its mark in the world and by careful recruitment of sales and production personnel Verner could continue to focus on R&D, which in a market that was changing rapidly with improved living standards and improved transportation, was an essential for company growth.

NC: How did the company grow?

FE: When I re-joined in the mid 1980s, I could see huge potential for growing the business in various markets but only by improving the organisation of production and sales. I also have an electronics background so could help to improve efficiency and act as a technical salesman for the company. It was the period when technology moved from valves to transistors, and Vetaphone was the first company to supply solid-state power generators, and later high-power units that were modular to allow different functionality and improved reliability.

NC: What was driving this growth?

JE: Verner was always pushing for greater integration of Vetaphone technology. He wanted our equipment to be viewed more as an intrinsic component of the production line rather than as an ancillary. We have continued this ethos by developing and bringing machines to the market that have minimal negative impact on production and resources. Our aim is single person operation of the entire production line, and you can only achieve this by integrating technology so that it improves reliability and increases output.

NC: What have been the major milestones along the way?

FE: Creating the electrical discharge reliably was key to the concept becoming a practical reality. Verner’s lifelong quest was to understand what he called ‘E-Norm’, but we know now as the ‘watt/density’ or ‘corona dose’ required to achieve the desired result. Once he’d mastered the technique, he had to sell it as a commercially viable process and continue to refine and develop its efficiency. In many ways, nothing has changed – we continue to invest heavily in R&D to allow the new complex substrates to match the packaging requirements demanded by today’s brand owners. It’s definitely a market where demand drives the technology.

NC: How do you think Verner would like to be remembered?

JE: To know that he is acknowledged as ‘the Godfather’ of surface treatment would both delight and amuse him – he was passionate about what he did, but very much a backroom scientist not an upfront salesman. That he pioneered an industry and founded what has become a world-leading company is, we think, a very satisfactory epitaph for him.

NC: And what would he think of Vetaphone and the surface treatment market today?

FE: We hope and believe he’d be very proud of how we have continued and developed his legacy. To be acknowledged as a world leading company is way beyond his imagination when he started back in 1951, and he’d be fascinated by how electronics and computer technology has been applied to basic science. Today’s market is highly complex both in terms of the materials being used and the applications they are required to fulfil – without his inquisitive nature and passion for invention, the packaging market as we know it today could have been so different!

/Ends

In memory of Verner Eisby – 1922-1993

Photo caption: It all began in a small workshop back in 1951 – today, Corona is the global standard for surface treatment

Source- The Publicity Studio.

Image Post category

Post category