Unilever predicts prices rises as packag...

The consumer goods giant reported its full year results with an underlying sales growth of 4.5% to €52.4bn; it is Uni

The consumer goods giant reported its full year results with an underlying sales growth of 4.5% to €52.4bn; it is Uni

“With the drive towards simplified packaging formats, and the need to develop mono material structures, Innovia Films

New Packaging Designs are necessary to revamp your product and to make your product stand out among many products. Customers always look for sweetness and light in their everyday product, Mischievous characters that make you smile, serene colorways, and harking back to simpler times by way of nostalgic design trends; these are just a few of the themes that are beginning to play out in 2022’s packaging design trends.

The New Era of 60's Psychedelia Some design trends are so sacred that they never slink out of style, and 1960s psychedelia definitely falls under that category. The contemporary take on the resurgence of ’60s psychedelia reminds us of a time of free love, peace, and happiness which we can’t deny we need more of as we head into the deeper waters of the pandemic. Distorted typefaces, ‘groovy’ waves, and pop colors set against contemporary products help these ’60s inspired packaging designs stand out and leave us with a feeling of peace and love, man.

The New Era of 60's Psychedelia Some design trends are so sacred that they never slink out of style, and 1960s psychedelia definitely falls under that category. The contemporary take on the resurgence of ’60s psychedelia reminds us of a time of free love, peace, and happiness which we can’t deny we need more of as we head into the deeper waters of the pandemic. Distorted typefaces, ‘groovy’ waves, and pop colors set against contemporary products help these ’60s inspired packaging designs stand out and leave us with a feeling of peace and love, man. Eccentric Text Centric Designing Sometimes people forget that type of design is an intricate art form in its own right, which is celebrated in this current trend for text taking center stage as a form of standalone art. All signs of photography and illustration are set aside to make room for standout typefaces, often using contrasting colors to give the design a boost of energy. This trend challenges everyday perspectives of fonts, where the font is seen as a piece of art over prioritizing readability.

Eccentric Text Centric Designing Sometimes people forget that type of design is an intricate art form in its own right, which is celebrated in this current trend for text taking center stage as a form of standalone art. All signs of photography and illustration are set aside to make room for standout typefaces, often using contrasting colors to give the design a boost of energy. This trend challenges everyday perspectives of fonts, where the font is seen as a piece of art over prioritizing readability. Finding Serenity in Packaging 2022 continues to be a turbulent time in the world, which makes the packaging design trend of finding serenity perfectly timed and just the calm we need in our homes right now. Muted and complementary colors give us that initial sigh of relief, whilst simplistic copy and minimal typefaces make for unfussy readability. The popularity for calming phenomenon ASMR even finds itself translating into packaging design, where shiny smooth or deliberately textured packaging surfaces add another dimension of serenity in packaging.

Finding Serenity in Packaging 2022 continues to be a turbulent time in the world, which makes the packaging design trend of finding serenity perfectly timed and just the calm we need in our homes right now. Muted and complementary colors give us that initial sigh of relief, whilst simplistic copy and minimal typefaces make for unfussy readability. The popularity for calming phenomenon ASMR even finds itself translating into packaging design, where shiny smooth or deliberately textured packaging surfaces add another dimension of serenity in packaging. Faux 3D Deco This innovative faux 3D graphic illustration brings a sophisticated and contemporary edge to this packaging design trend. Playing with depth and illusion is a sure-fire way to get consumers to stop and look, almost literally jumping out at you demanding your attention. As faux 3D is such a technical effect to create, it shows the consumer that you’re at the forefront of trends and technology, which basically translates into ‘this product is worth the money—it’s an ideal design idea for tech products on the more expensive end of the spectrum.

Faux 3D Deco This innovative faux 3D graphic illustration brings a sophisticated and contemporary edge to this packaging design trend. Playing with depth and illusion is a sure-fire way to get consumers to stop and look, almost literally jumping out at you demanding your attention. As faux 3D is such a technical effect to create, it shows the consumer that you’re at the forefront of trends and technology, which basically translates into ‘this product is worth the money—it’s an ideal design idea for tech products on the more expensive end of the spectrum. Mesmerizing Color Mist Plain white packaging is given an injection of life with sprayed misted color pops. The trend for color mists has taken over the Instagram design world, possibly because of its calming effect which stops you in your tracks mid-scroll. This design effect is so mesmerizing and enigmatic that it’s hard to place how a designer might create this effect, however a mix of over-blurring and adding noise to a color pop on Photoshop might just do the trick.

Mesmerizing Color Mist Plain white packaging is given an injection of life with sprayed misted color pops. The trend for color mists has taken over the Instagram design world, possibly because of its calming effect which stops you in your tracks mid-scroll. This design effect is so mesmerizing and enigmatic that it’s hard to place how a designer might create this effect, however a mix of over-blurring and adding noise to a color pop on Photoshop might just do the trick. Minimal Inside, Maximal Inside You know a jacket is special when its lining is just as beautiful as the outer shell? Well, the same can be said for packaging design. What a treat it is when you open up your minimalistic packaging to reveal a maximalist and beautifully crafted interior. Simplistic and minimal logos are carried through from the outside-in, to reveal bright colors and maximalist illustrations, leaving consumers delighted and with your brand top of mind.

Minimal Inside, Maximal Inside You know a jacket is special when its lining is just as beautiful as the outer shell? Well, the same can be said for packaging design. What a treat it is when you open up your minimalistic packaging to reveal a maximalist and beautifully crafted interior. Simplistic and minimal logos are carried through from the outside-in, to reveal bright colors and maximalist illustrations, leaving consumers delighted and with your brand top of mind. Perfectly Imperfect Raw Materials Earthy imperfect textures remind consumers where brands are getting their materials from, a must for brands that want to push their eco-friendly ethos and tap into the consciousness of consumers’ concerns with the climate crisis (excuse the tongue twister). As the industry is rapidly changing to favor brands with sustainability at the core of their offering, ethical and compostable packaging is one of the many things you can do as a brand to show you’re serious about your sustainable positioning. Off-white, recycled textured materials also provide a beautiful backdrop for printed ink, creating a delicate distortion of color.

Perfectly Imperfect Raw Materials Earthy imperfect textures remind consumers where brands are getting their materials from, a must for brands that want to push their eco-friendly ethos and tap into the consciousness of consumers’ concerns with the climate crisis (excuse the tongue twister). As the industry is rapidly changing to favor brands with sustainability at the core of their offering, ethical and compostable packaging is one of the many things you can do as a brand to show you’re serious about your sustainable positioning. Off-white, recycled textured materials also provide a beautiful backdrop for printed ink, creating a delicate distortion of color. Cut 'n' Paste Color Layering The love for collage lives on as an integral form of design, this year with more of a focus on geometry and the layering of colors. The ripped raw edges of paper give a nod to recyclable materials which is handy for tapping into the eco-conscious market. Where college is still very much on-trend in the independent scene, using collage in your packaging design allows you to connect to that specific high-earning creative audience.

Cut 'n' Paste Color Layering The love for collage lives on as an integral form of design, this year with more of a focus on geometry and the layering of colors. The ripped raw edges of paper give a nod to recyclable materials which is handy for tapping into the eco-conscious market. Where college is still very much on-trend in the independent scene, using collage in your packaging design allows you to connect to that specific high-earning creative audience. Mischief Illustrated The mischievous illustration trend gives a knowing nod to its viewer with its ironic childlike drawings and teeters on the edge of meme culture with its satirical style. As with the rubber hose characters, these youthful drawings leave you smiling, if not a bit puzzled how they’ve made their way onto your packaging. After all, humor is one of the quickest ways into someone’s heart.

Mischief Illustrated The mischievous illustration trend gives a knowing nod to its viewer with its ironic childlike drawings and teeters on the edge of meme culture with its satirical style. As with the rubber hose characters, these youthful drawings leave you smiling, if not a bit puzzled how they’ve made their way onto your packaging. After all, humor is one of the quickest ways into someone’s heart.Serene colorways, charming characters, and nostalgia; if there’s anything we can learn about 2022’s packaging design trends it’s that consumers are looking for positive vibes.

Setting up Recycablity at the heart of Packaging through using different Simplication and Standardization could Save our Planet

Plastic is a phenomenal material. It’s inexpensive, durable, flexible and multipurpose. And to whats best if you notice it has gained spectacular growth in demand over the last century.

As we all know, this success is both a blessing and a curse. The challenging pollution issues that plastics creates, from the release of carbon dioxide emissions to waste found in waterways and oceans, has vilified it.

Recycling more plastics could reduce incineration emissions, avoid mismanagement of exported waste, and replace the need for the production of new plastics. However, as things stand, current recycling commitments will make very little impact.

The report estimates that by 2040, 29 million metric tons of plastic per year will have entered the oceans. That’s the equivalent to 50 kg/110+ pounds of plastic per meter of coastline worldwide. Because plastic remains in the ocean for hundreds of years and may never biodegrade, the cumulative amount of plastic stock in the ocean could grow by 450 million metric tons in the next 20 years.

We need to take drastic steps, one of which involves boosting our recycling capacity. Strange as it may seem, a good place to start is our packaging.

It’s a sobering fact that many packaging items we see have been designed with the primary purpose to engage with the consumer, protect the contents within, and tell a strong brand story. Recycling features that create closed loop opportunities are woefully low on the list of priorities.

Consider the fact that redesigning a pack or bottle to be as recyclable as possible should improve its quality and reduce its cost.

Let’s deep dive into this, starting at the top.

It might seem like a small thing, but over the last 30 years, more than 20 million bottle caps and lids have been found during beach cleanups globally. We have lost track of how many bottle caps enter our oceans and wash up on shore, yet these caps are among the five main ocean trash items that are deadly to sea life. Here are the changes that would solve this deadly issue.

Tethered.

In an ideal world all caps remain attached to the bottle. By tethering, the total volume of caps being recycled would be boosted to provide more material for recycling back into caps. Current commercial designs for tethering caps to bottles are increasingly being light-weighted and would be a minor cost for drinks companies, but a huge benefit to the environment.

Simplified.

Most PET bottle caps are made of either high-density polyethylene (HDPE) or polypropylene depending on the brand owner. Separating them into their relevant polymer types is a nightmare and, as a consequence, they end up in low-value applications as a mixture or in a landfill due to their size and separation from the bottle.

There is no reason why we can’t adopt one polymer type per country to simplify the separation problem.

Natural.

If all caps were either their natural color white we would capture, recycle and reuse all caps ad-infinitum. Instead, we are literally drowning in a sea of multicolored caps.

Do we consumers truly require a color-coded cap to identify our favorite beverage? Or would we prefer a cleaner planet?

All label, no glue.

Moving on down the bottle to the label…Evian recently made a bold sustainability statement with its label-free bottle. It may seem like a minor detail, but the fact that they have kept the pink cap still leaves room for improvement. Were Evian to create a totally “naked” bottle, from cap to base, their statement and their action would be even more impactful.

Brands need to ditch pressure-sensitive labels that contaminate the recycling streams and instead opt for stretch labels or shrink sleeves. Aggressive glues are particularly an issue for recyclers of PET and HDPE packaging; options like self-peeling labels are already on the market. Going further we need to ensure that these labels don’t bleed inks. The labels themselves need to be readily separated and recycled to avoid any unwanted waste.

None of the above suggestions should impact on the brand’s visual cues, these are technical details that can be easily addressed and would make a huge difference to overall recycling streams.

Back to basics: The container.

It all starts with the container. Take an HDPE milk bottle, for example. Many resin manufacturers use the minimum required stabilizer that prevents reactions that can lead to polymer degradation during processing. This in turn impacts on the quality of the recycled material, especially when it enters a circular economy where plastics will go through the loop many times. This is a critical concern as the level of recycled content rises beyond 50%.

If instead of being minimally stabilized, bottles were designed for constant recycling, the plastic quality would be maintained and this would improve recycling rates. In many cases, the stabilizers need to be present during initial processing where thermo-oxidation reactions can occur that may trigger later impacts through gel formation or photo-chemical reactions during outdoor exposure.

Color free

As for the rainbow of colors brands are currently deploying, this only goes to show how little deep recycling is considered during a sustainably minded packaging development process.

Colored plastic packaging is much harder to recycle economically than clear plastic because there is little demand for the resulting “recycling grey” that occurs when containers of all colors are combined. Unscrambling the colors is possible via sorting equipment, but the multitude of color variants means that it is impossible to produce a color that would suit any one brand owner.

The irony is that in many cases the colored plastic is often covered by a large label as a means of marketing making the package below invisible. It might as well be grey or natural and save the pigment costs and improve the final recyclability!

There is no doubt that color is one of packaging designers’ key tools, yet the impact on a pack’s recyclability is huge. Tomorrow’s ideal bottle would be either transparent, white or self-colored grey and have easily removable shrink sleeves would be used to ensure the brand is loud and clear.

Tomorrow’s bottle.

If we were to design the type of highly recyclable bottle I have described above, we would end up with a very close replica of a brand’s original product. Only an expert would be able to notice the difference. Is cost creating a roadblock?

Starting with the caps produced of one polymer type in clear or white would mean a greater opportunity to recycle caps back into new caps that would reduce the need for new virgin resin.

Eliminating colored bottles would vastly reduce masterbatch costs and focus all the design cues on the label — made with self-peeling or water-soluble glue — or stretch-sleeves. Recycling yields would increase making high-quality recycled material more plentiful and less expensive. As a result, the brand recycling story would be genuine.

These type of design details would greatly contribute to the total recyclability of a pack and only require a change in mindset rather than a paradigm shift.

Challenging the status quo is a matter of adopting good design principles that embrace recyclability to the core.

Ultimately this is not about creating a green image, but about developing a deep green and lighter footprint that is sustainable.

Wrapping up.

There is no reason not to make these changes now. We have the cutting edge technology to identify, sort and decontaminate post-consumer waste — all we need is for brands to embrace the notion that what we currently deem ”‘recyclable” is not enough and we need to actively create the “really recyclable” pack.

Working out good design principles for recycling requires brand owners to step up and voluntarily take responsibility for every facet of their packaging.

Please remember these two takeaways:

We need to shed the fallacy that our current recycling efforts are sufficient, because they are not.

We all share this one planet and it is time to make a real stand for how we look after it.

Aritcle Source by- Edward Kosior

Planet Paper Box is a turnkey solution provider, having worked with some of the largest eCommerce and warehouse provi

How important is your product’s packaging to your customers? Maybe more than you think.

While some importers obsess about the look and feel of their packaging, many struggle just to deliver their products to customers unharmed.Survey of 2,000 online shoppers found that one in ten have received damaged items.

Many factors can impact the condition of your packaging and the products inside. Everything from packaging materials used, to regulations in your market of sale and even the climate throughout your supply chain can hinder your ability to deliver a quality product to your customers.

Pre-shipment inspection can go a long way in helping you verify both product and packaging quality. But when serious packaging problems persist you may need greater precision with packaging testing in a qualified lab. Any one of these nine lab tests on our list could help you solve these quality problems and save your products.

Stacking of shipping cartons is common in factories and warehouses for the storage, shipping and distribution of orders. Sometimes a factory might have limited storage space available and they might improperly stack too many boxes on top of each other to conserve space. Improper stacking can stress shipping cartons and cause them to collapse

The edge crush test (ECT) was developed in the 1990s as shipping on pallets and stacking of cartons became more popular in international supply chains. Evaluating a carton’s strength in isolation, as was common before, failed to measure its performance in actual shipping situations. The edge crush test measures the compressive force a cardboard material can sustain in its vertical or loading direction before collapsing.

A finished box’s compression strength is defined by the amount of force needed to crush a section of cardboard when standing on its edge. During this test, a load is applied to the edge of a small sample of the packaging material when standing on its end until it collapses.

2. Bursting Strength Test (BST)

The burst strength test, also known as the Mullen test, is commonly compared to the edge crush test, as they both evaluate the strength of corrugated or cardboard materials. Together these two tests are the most commonly recommended packaging lab tests for importers.

But that doesn’t mean importers should use these two tests interchangeably, as the tests measure different things. Bursting strength is the measure of the force required to puncture through a corrugated board. Rather than applying force at the edge, like in the edge crush test, force is applied on its flat side.

The burst strength test is an older test than the edge crush test and provides a more general assessment of a carton’s strength. Importers shipping products individually might find a burst strength test more helpful as their shipments might be more subject to rough handling than products stacked on pallets.

3. Puncture Resistance Test

Shipping your products isn’t just about shipping, but also shipping and handling. Tens of people might handle your packages before they reach the end customer. Cardboard can easily be punctured during handling by factory staff and logistics personnel if the box collides with another object. The corner of other boxes, sharp edges of a truck or shipping container or a sharp product within the box all might puncture your shipping cartons.

The puncture resistance test aims to simulate such collisions by evaluating the energy required to create a hole in the packaging material. The bursting strength test and the puncture test both verify the susceptibility of packaging materials to damage through puncturing. But the puncture resistance test uses a puncture resistance tester with a pendulum arm and a steel pyramid head that physically hits the cardboard at a 90-degree arc.

4. Climate Conditioning for Different Enviroment

The climate of your sourcing destination could be drastically different from that of your target market. Many popular sourcing locations in Asia have a tropical or subtropical climate and regularly experience high humidity levels. But you might be shipping to a country in US or elsewhere with a much cooler, dryer climate. Packaging materials might warp, mold or otherwise deteriorate under different climates.

Not only do you need to consider the climate of your sourcing location and target market, but also the climate conditions your shipment will experience during transit. Shipping by air will expose your packaging and products to higher altitudes and air pressures. Shipping by sea might expose your products to water damage if packaging materials aren’t adequately sealed.

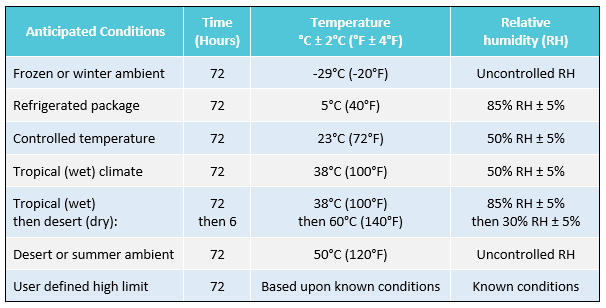

During a climate conditioning test, the packaging material is placed and kept within a specified climatic atmosphere chamber for a length of time, often 72 hours, to reveal any changes in the physical properties of the material. Calibrated environmental chambers can simulate elevated temperatures, cold/sub-zero temperatures and elevated humidity levels, as shown in the table below.

ISTA recommended conditioning profiles:

5. Vibration test to simulate transit Vehicle Vibrations

Modern automobiles drive a lot smoother than the first Model T designs of over a century ago. But transport through a number of vehicles, including trucks and semis, still often produces vibration that can affect a shipping carton, its interior packaging, packaging closure and the products inside. And your shipment might be subjected to additional bumping, shocks and vibration when traveling in less developed countries with unpaved roads.

The vibration test is meant to assess the performance of a container, including the interior packing and closure, in terms of its strength and the protection it provides the products within.

There are four different package testing methods meant to simulate different levels of vibration a container might be subjected to during transit. Importers should assess both their packaging materials and method of transport to determine the appropriate packaging testing method for their shipment. These test methods include:

6. Compression Strength for Packaging

Like the edge crush test, a compression test can be helpful to evaluate packaging materials that might be stacked or compressed in small spaces with other boxes and items.

While the edge crush test evaluates cardboard at its edge, force can be applied during the compression test to the container’s faces, to diagonally opposite edges or to corners. You can also use this same standard to evaluate other materials aside from cardboard, like drums, pails, bottles and tubs.

The compression test can be used to measure the ability of a container to resist external compressive loads applied to it. The box is gradually compressed between two parallel platens to reveal any bulging, distorted or damaged shape, damaged corners or damage to products within.

7. Shock Test for Packaging

A shock test might seem similar to the carton drop test importers often request among on-site packaging testing during a pre-shipment inspection. Free-fall drop testing like the carton drop test is easy to perform and can reveal issues in packaging materials, methods or assortment through a series of drops. But importers seeking more comprehensive and statistically accurate packaging testing can consider a shock test performed in a laboratory.

With an on-site carton drop test, the orientation of each drop is manually determined by the inspector. While there are standards for how to orient the carton for a series of nine drops, manual packaging testing still cannot provide statistical accuracy of an exactly perpendicular drop with the dropping surface. A machine can determine an exact 90 degree drop from the corner of the shipping carton and the dropping surface, while a human might drop the carton at a 92- or 95-degree drop.

How much difference does a few degrees really make? ASTM testing found a variation of as little as two degrees from perpendicularity resulted in an eight percent lower acceleration and dispersal of impact energy. So a less precise on-site carton drop test alone may be inadequate in revealing important vulnerabilities in your packaging.

8. Reduced pressure test for Rigid Containers

Leak tests are essential for food and beverage products, liquid cosmetics and any other liquid products. Often a reduction in air pressure during air transit can cause containers to rupture, crack or burst. And it’s not like you can just scoop up any leaked liquids from your broken containers and repackage them on arrival. Both the products and your containers will no longer be sellable or safe for consumption or use.

So how can you ensure your liquid products remain safely incased in their containers throughout shipment? Similar to a climate conditioning test, a leak test simulates elevated air pressures using a calibrated vacuum chamber. Initial pressure applied within an airtight chamber is measured against the final pressure after a period of time. Any changes in these two measurements will reveal leaks or other concerning packaging vulnerabilities.

9. Testing Packaging for Compliance with Toxin Regulations

Most of the above tests have focused on evaluating a packaging material’s strength and integrity. But another important role of packaging testing for importers is ensuring compliance to legal regulations. Failing to comply with legal regulations for packaging can put your brand at risk for a number of monetary fines, lawsuits and other liability issues.

The Model Toxics in Packaging Legislation establishes requirements for the reduction and elimination of four heavy metals, namely cadmium, lead, mercury and hexavalent chromium in packaging sold or distributed in nineteen U.S. states. The Model is more restrictive than the European Union Packaging Directive (94/62/EC, Article 11), so importers selling in both U.S. and European markets will need to ensure compliance under both standards.

The legislation holds all manufacturers, suppliers, product manufacturers and distributors of packaging and packaging components accountable for testing and ensuring the elimination of toxins. Lab testing is the only way to determine compliance to these regulations.

In addition to carrying out lab testing, ask your supplier to provide a Certificate of Compliance after testing has verified the level of chemicals is within the allowable threshold.

Do you really want to leave packaging quality control up to your factory? The factory that manufacturers your product might not also manufacture its packaging. It’s common for factories to outsource packaging manufacturing to one or more sub-suppliers. And your factory’s standard for packaging quality control might not be as high as yours, which makes packaging inspection and testing all the more vital.

Verifying packaging quality through both pre-shipment inspection and lab testing ensures your products will arrive on your customer’s doorstep undamaged and in top condition.