Refres now increase production capacity ...

Following a significant investment in the biggest-ever Sidel Combi for CSD (carbonated soft drinks) in 2011, Refres Now, the Argentinian producer of the Manaos brand of beverages, has recently installed a further blow-fill- cap solution. With the new Sidel Matrix™ Combi, Refres Now can expect comparable savings of 45% in its energy consumption. It also anticipates a significant decrease in water consumption and an improvement of 40% in the plant's total production output.

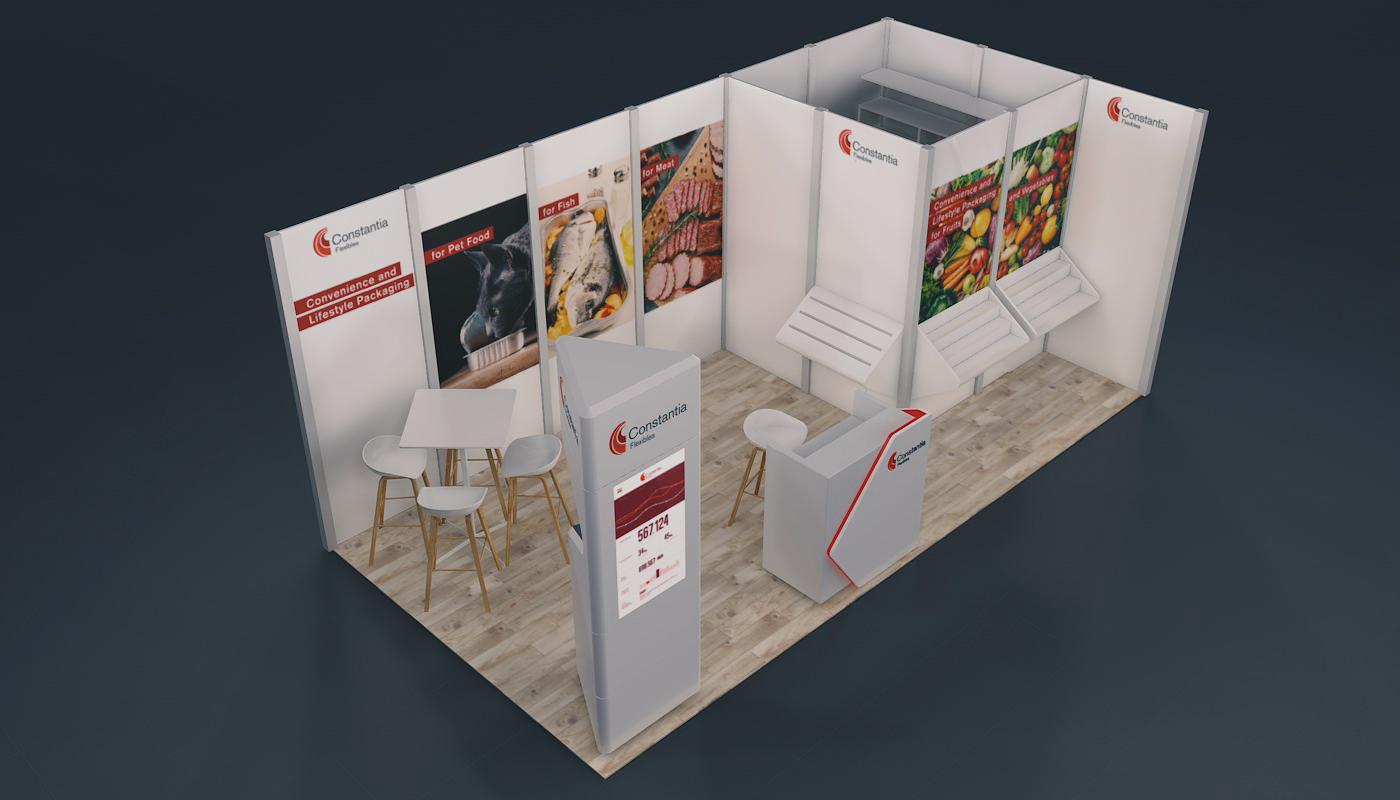

The Sidel Matrix Combi is part of a new line, installed as an extension of the company’s production facility in La Matanza. This expansion of the Manaos plant is the result of a 12 million dollar investment, which covers also the opening of a new warehouse for finished product storage. It was officially inaugurated by Argentina's President, Mauricio Macri, at a special event.

The company's working relationship with Sidel first began back in 2005 when Refres Now was originally founded. In 2011 came a world record, when the Argentinian beverage producer turned to Sidel for what was, at that time, the world's largest Sidel Combi ever built for filling carbonated soft drinks. It was a high-tech solution for bottling family pack sizes, which were in great demand locally. Looking back to that experience, Marcos Pilati, Sales director for Mexico and North Hispanic zones at Sidel, comments – “Refres Now has benefitted from the performance of our integrated solution. The resulting top quality bottles were better suited to withstand the pressures of transportation and the challenges of the entire supply chain. Despite the difficult economic situation within the South American country over recent years, the equipment we have installed has been helping Refres Now over-perform their objectives. As a result, they now see Sidel as a strategic partner in their bottling operations.”

Consequently, Sidel was the first choice when the beverage company needed to increase production capacity. The new Sidel Matrix Combi installed at the Manaos plant marks two milestones. Via the savings made possible by the Sidel Matrix blower, it allowed Refres Now to cut energy consumption by 45%. This is important to many beverage producers, both in terms of sustainability and the often-significant cost savings it represents, but vital for the Argentinian manufacturer given the energy issues within the country. Additionally, it features a Sidel MatrixSF300 FM filler with 162 valves - one of the biggest electronic fillers in the world that boasts an output speed of 32,000 bph (bottles per hour). The integrated solution also includes Sidel’s Blendfill configuration, combining mixer and filler in a single system for top quality carbonated soft drinks. Utilising the mixer’s beverage tank as a shared tank with the filler, the configuration avoids redundant pressure and level control functions, while reducing consumption of CO 2 as well as the footprint of the equipment. To answer the customer’s needs as for flexibility and efficiency, the Combi can produce multiple bottle sizes - ranging from 0.6 to 3.0 litres.

The Sidel Matrix Combi is a flexible and hygienic solution offering an extensive range of configurations. It is an integrated blow-fill- cap solution within a single, small controlled production environment in which intermediate conveyors and equipment are eliminated to deliver outstanding hygiene performance while simultaneously cutting costs. With efficiency levels up to 4% higher than standalone machines, the Combi cuts operating costs by up to 12%, offering faster format changeovers, lower energy consumption and savings in labour, raw materials, maintenance time and spare parts. Furthermore, it uses up to 30% less floor space, compared with traditional standalone equipment.

The company now relies on Sidel, its equipment and its services, including, notably, the professional advice and support provided regularly by its personnel. Walter Canido, Operations Director and one of the company owners of Refres Now, said: “We celebrate the start-up of our line number 9, and for us every new line means a great success. Sidel has an impeccable trajectory in technology for the bottling industry, but above all, the magic ingredient for the equation to work is its people and for us that is more important than the machine itself. Our next step is line number 10, and the future ... is infinite."

Refres Now already has the largest bottling plant in Latin America and one of the largest soft drinks production sites in the world. The company manufactures the Manaos brand in five different flavours: cola, orange, lemon-lime, apple, and grapefruit. In a daily production output of over 3.5 million litres, it also produces many more other leading products, which include sodas, waters and flavoured waters.