Williamston (MI, USA), 26.11.2019: The Bekum group celebrated recently three anniversaries – 60 years Bekum in Berlin Germany, 50 years Bekum in Traismauer Austria und 40 years Bekum in Williamston, USA. As part of the celebrations at the American location, the groundbreaking ceremony for the expansion of production capacities was made on November 26, 2019. A new building with a production area of 3,700 m² and almost 700 m² of office space will be added. This increases the site's operational area to more than 15,000 m².

Michael Mehnert, Managing Partner, who traveled from Germany for this celebration, comments proudly: “My father founded this company sixty years ago. Today I’m standing here and lay the foundation for a new production hall in order to be able to serve the continuously increasing demand in the USA in the future!”

„This is a historic week for Bekum America,” said Steve London, COO and President of Bekum America Corporation. “The groundbreaking on our new facility was a great kick off to our 40th anniversary celebration with our dedicated employees. The Bekum team has continually been providing state of the art products for our clients, and this event is the perfect opportunity to celebrate all the individuals who complete Bekum.”

Bekum America was established in 1979 with the mission to introduce top quality blow molding machinery, designed to produce plastic bottles, containers and other large plastic parts in the North American marketplace, via blending German design and technology with American skill and ingenuity. Bekum’s customer base includes large multi-national customers, as well as owner/operator plastic bottle manufacturers.

Released for Publication – Copy Requested.

Volume: 272 words | 1.746 characters

Captions:

Caption 1 (opening image): Managing Director Michael Mehnert (2nd from left) during the at groundbreaking with the managers of the US subsidiary CFO Owen Johnston, Chairman Martin Stark, President & COO Steven London (from left)

Image sources: All images are from Bekum (unless otherwise indicated)

About Bekum +++++++++++++++++++++++++++++++++++++

Pioneer and Trendsetter in Blow Moulding Technology

Founded in Berlin in 1959, Bekum Maschinenfabriken GmbH is one of the world’s leading manufacturers of extrusion blow moulding machines.

Founder Gottfried Mehnert conceived the name Bekum as the acronym (Berliner Kunststoff Maschinen).

The company began to flourish in its founding year with the development of the world’s first neck-rim calibration. Numerous innovations and patents followed, confirming that Bekum, with its innovative and customer-oriented machinery solutions, has always been ahead of its time – and remains so to this day.

When innovative and economical machinery solutions with high productivity for individual packaging requirements of hollow packaging are in demand, then Bekum, with 60 years of experience in blow-moulding technology, is the first choice worldwide.

Product Range and Applications in Food and Non-food

With future-oriented and reliable production processes and fully electric, as well as hydraulic machinery for the commercial production of blow moulded containers ranging from 5 ml to 3000 l, Bekum offers everything for plastic packaging from one source.

Philosophy of the Company

Building and maintaining long-term relationships with market partners through future-oriented, predictable company policy determine the actions of the first and second generation of the family, represented by Michael Mehnert. This strategy ensures the jobs of dedicated and experienced staff. The preservation of traditional structures, an established network of partners and far-sighted adaptation to change form the basis for continuous development and inspiration for the company in the interest of partners, customers and employees.

Innovation and Technology

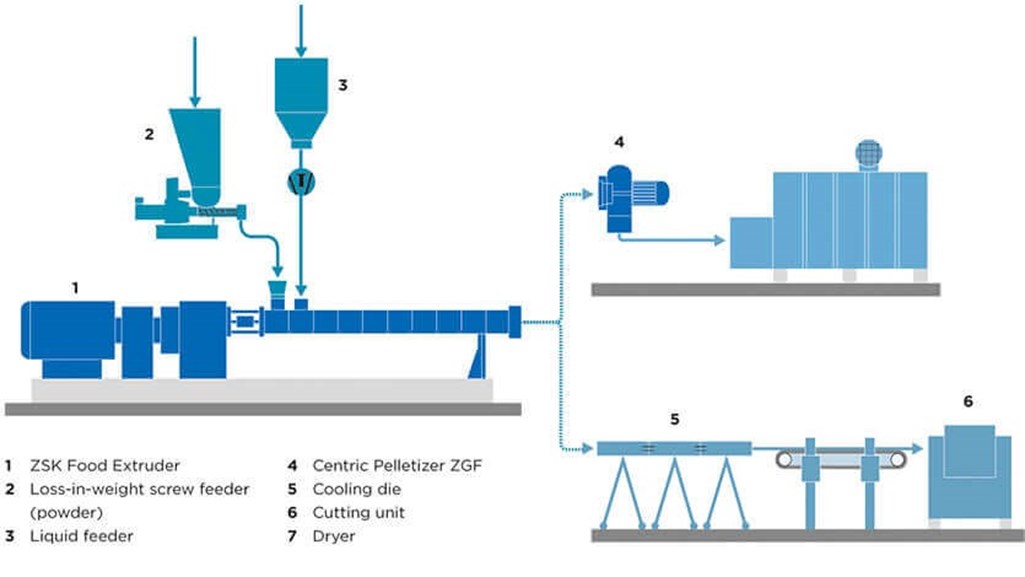

Process reliability, availability, efficiency and sophisticated design characterise the high standard of Bekum production lines for blow moulding. Bekum contributes the expertise that has grown based on these references, associated with various patents in blow moulding, to the fulfilment of every customer requirement.

The level of process design is key for process reliability, reproducibility, parts quality and cost-efficiency. A high-quality production line for extrusion blow moulding, consisting of machine, die and automation which is impressive in terms of speed, wear resistance, availability, process reliability and stability alike, is critical for return on investment (ROI) and the level of added value.

Facts and figures

With 18,000 machines delivered and installed worldwide - about half of them still in use - the Bekum Group has achieved by far the largest production of blow moulding machines of any brand.

The Bekum Group serves approximately 100 countries around the world directly or through representatives.

Today, 350 employees work for the Bekum group worldwide at three locations in Europe and in the US (Berlin (Germany), Traismauer (Austria) und Williamston (USA)).

Our Technology – Your Success

Berlin | Deutschland

Traismauer | Österreich

Williamston | USA

Bekum Maschinenfabriken GmbH

Kitzingstraße 15/19 • 12277 Berlin • Deutschland

Tel.: +49 (0)30 7490-0 • Fax: +49 (0)30 7490-2441

E-Mail: sales@bekum.de • www.bekum.com

Geschäftsführer:

Gottfried Mehnert

Dipl.-Ing. Michael Mehnert

Ust.-Id.-Nr.: DE136701335

Deutsche Bank AG, Filiale Berlin

BIC DEUTDEBBXXX

IBAN: DE55 1007 0000 0386 9500 00

Amtsgericht Charlottenburg, 92 HRB 3533