The company Ekro in Apeldoorn (NL), part of the VanDrie Group, is a renowned producer of veal.

At the business park along highway A1, approximately 400,000 calves are processed into high-quality meat products every year, which are mainly distributed in Germany, France and Italy. In

2020, Ekro made significant investments in its packaging department, resulting in four new thermoformer lines. We spoke with Christian Scholten, Project Manager a.i. at Ekro, and Anjo Kaatman, Head of Technical Service within the company, about the recent installation of these lines and the challenges such a project entails.

High-quality veal with attention to the animal

What once started as a municipal slaughterhouse in the centre of Apeldoorn is now an ultramodern production company on the outskirts of the city with approximately 750 employees. Ekro works in two shifts per day on the tastiest veal products. The new building at its current location along highway A1 was constructed in 1989, not long after the company was incorporated by the Van Drie family. Today, the VanDrie Group includes Dutch companies such as ESA and T. Boer & zn, but also Sobeval and Tendriade in France.

‘When you ask for veal, we serve a concept’, that is the starting point of Ekro. The company supplies high-quality veal products all over the world that are tailored to the wishes of the customer, such as whole veal breast or veal roulade for the catering industry, but also consumer products such as veal burgers or steaks. Animal welfare, food safety and sustainability are of utmost importance. This means that Ekro's products fully meet the contemporary requirements of discerning chefs and consumers. All employees, but also each supplier of the calves, work continuously to improve animal health and welfare.

Full traceability

Veal is an appreciated delicacy due to its fine structure, high nutritional value and subtle taste. It is easy to digest, low in cholesterol and rich in vitamins and minerals. That is why the product is widely used and highly valued in international kitchens. Ekro works with traditional wholesalers, retailers, food servic and food manufacturers. Orders range from the delivery of complete carcasses to the delivery of kitchen-ready consumer products.

Christian Scholten, Project Manager at Ekro: “What makes Ekro unique is the quality we deliver. Our company is part of a complete chain, from the feeding of the calves to the packaged end product. In addition, Ekro has been committed to traceability for several decades. The abattoir and deboning section are equipped with high-tech hardware and software, which connect seamlessly to each other, so that full tracking and tracing of the products is guaranteed. For example, the customers of Ekro, primarily the wholesaler, can always enter the stated barcode for each product on a special website to view the complete life cycle of the meat.”

Impossible to break

As Head of Technical Service, Anjo Kaatman is responsible for Ekro's existing machinery. Within the company’s Project Office, Christian Scholten, together with four other colleagues, is constantly working on renewal processes in the broadest sense of the word. Recently, both men worked together in a large investment project in the packaging department of Ekro. The aim was to modernize a number of existing lines, so that they could work even more efficiently. For example, the same thermoformer has been used since 1999 for packaging the by-products, especially organs. This machine, an RE3, was once purchased from the company Repak B.V. in Emmen (NL), a Dutch family business, just like the VanDrie Group. There is a great anecdote about the installation of the RE3. At the time, the machine was delivered by truck and brought to its destination in one piece on wheels. However, it turned out that there suddenly was a wall that had not yet been there at the time of purchase. With two colleagues quicky gathered from Emmen, the RE3 was taken apart and put back together in the right place, so that it could still be installed over the weekend. Since 1999, the line has been running 16 hours a day, where cleaning takes place every evening and maintenance is done twice a year. Anjo Kaatman: “The RE3 has always functioned without problems in our challenging production environment until the end of 2021.”

The importance of good maintenance The RE-series thermoformers are still built in Emmen, but since 2007 they have been offered in the Benelux under the brand name SEALPAC. The advice, sales and maintenance are done by Ultrapak B.V. in Nijkerk, the exclusive distributor for SEALPAC thermoformers and traysealers in the Netherlands, Belgium and Luxembourg. Anjo Kaatman: “We have had an exceptionally good relationship with Ultrapak from the start. They take their responsibility and meet the set deadlines, also with regard to the agreed service contracts. Installation of new machines, but also the maintenance of existing machines, must take place with us during the weekend. The requirement is then that the machines have to be running again on Monday morning at 6.00 am, and that has always been successful so far.”

With the RE3 in use for more than 20 years, and a number of other lines that could use a facelift, the inevitable question of replacement came in 2020. To this end, a large project was started within Ekro, in which distinct options were examined. Revision of the existing machines was still a possibility, but replacement turned out to offer the most benefits in the end. Ultrapak, in the form of contact person Andres Vos, provided an extensive analysis. As part of the project, a visit was made to the factory in Emmen. For Christian Scholten, it was the first time. He remarks: “It is a very neat factory, where you can clearly see the production process of the machines, from drawing to assembly. Furthermore, it is obvious that the factory is constantly investing in production resources.”

Four new lines

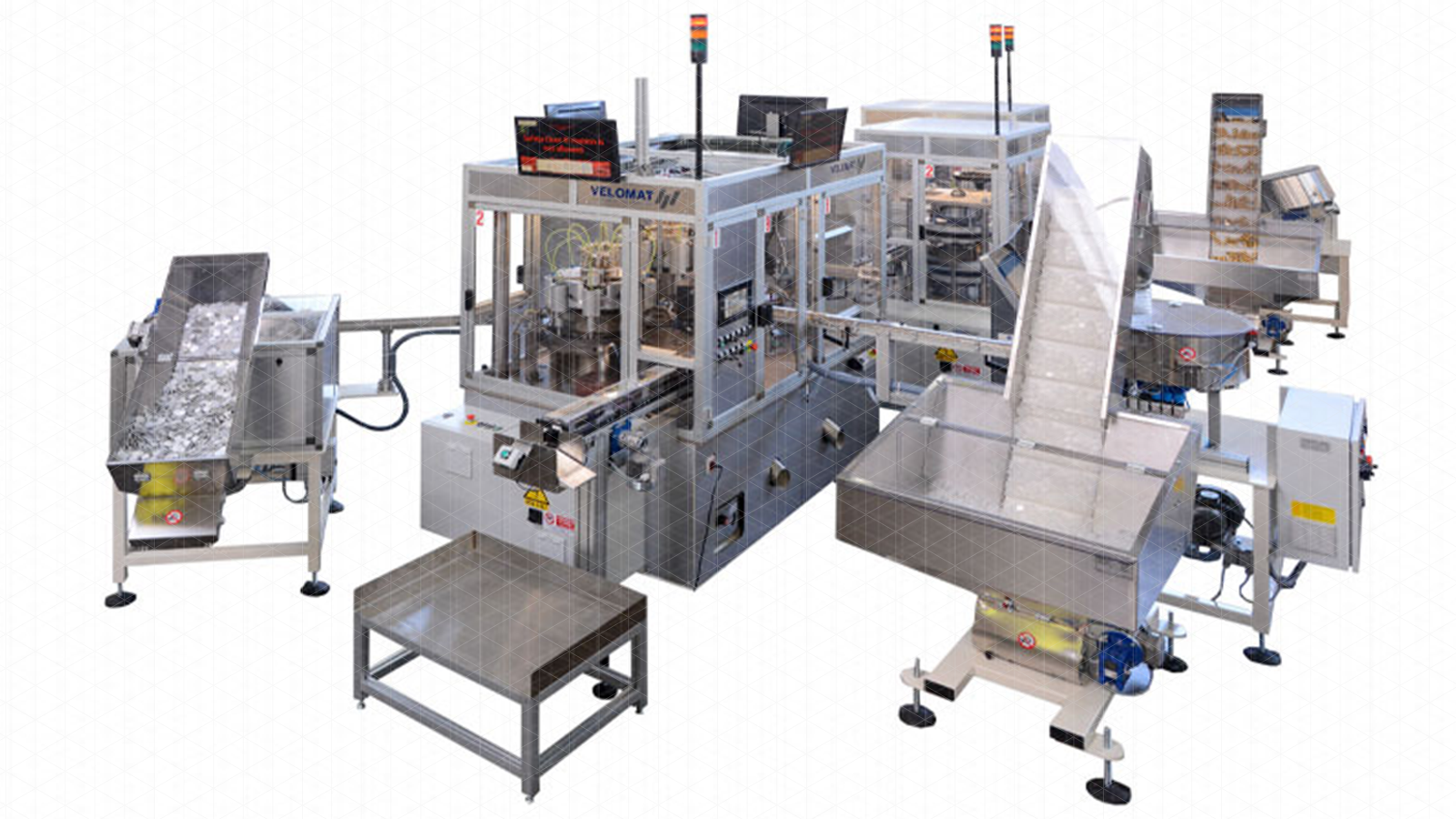

Ultimately, Ekro decided to invest in four SEALPAC thermoformers: an RE30 tandem machine for packaging the by-products and three RE25 thermoformers for packaging fresh veal in various weights and sizes, including entrecote, fillet, escalope, rib-eye and steak. Anjo Kaatman: “The first two machines were installed in September 2021, and the last two followed in November. In both cases this happened over the weekend, and in both cases the machines were ready for production by 6:00 am on Monday morning. As we are used to from Ultrapak!”

The three RE25 thermoformers are located right next to each other in the same production hall. Because of the tight space there, including a few awkward pillars, the machines were designed to fit. Each of the RE25 thermoformers is suitable for a fixed packaging format, which is tailored to the weight and/or dimensions of the various veal products. The RE30 is located in a separate hall, where the by-products are packaged, such as liver, heart, tripe, sweetbreads, etc. Christian Scholten: “This line has regular changes during the day. By choosing a tandem machine with two forming stations, suitable for two formats (roughly 4 kg and 5 kg), we can now change at the touch of a button. This results in enormous time savings. Our staff is very economical with and proud of this line!“

All SEALPAC machines are equipped with product support due to the heavier packaging. This prevents the film from slipping out of the chain. Furthermore, all machines have central lubrication, so that maintenance is minimized. Anjo Kaatman adds: “The SEALPAC machines are characterized by their simplicity and reliability. I therefore know that our staff can quickly familiarize themselves with these machines. The touch-screen monitor of the RE series is also easy to operate.”

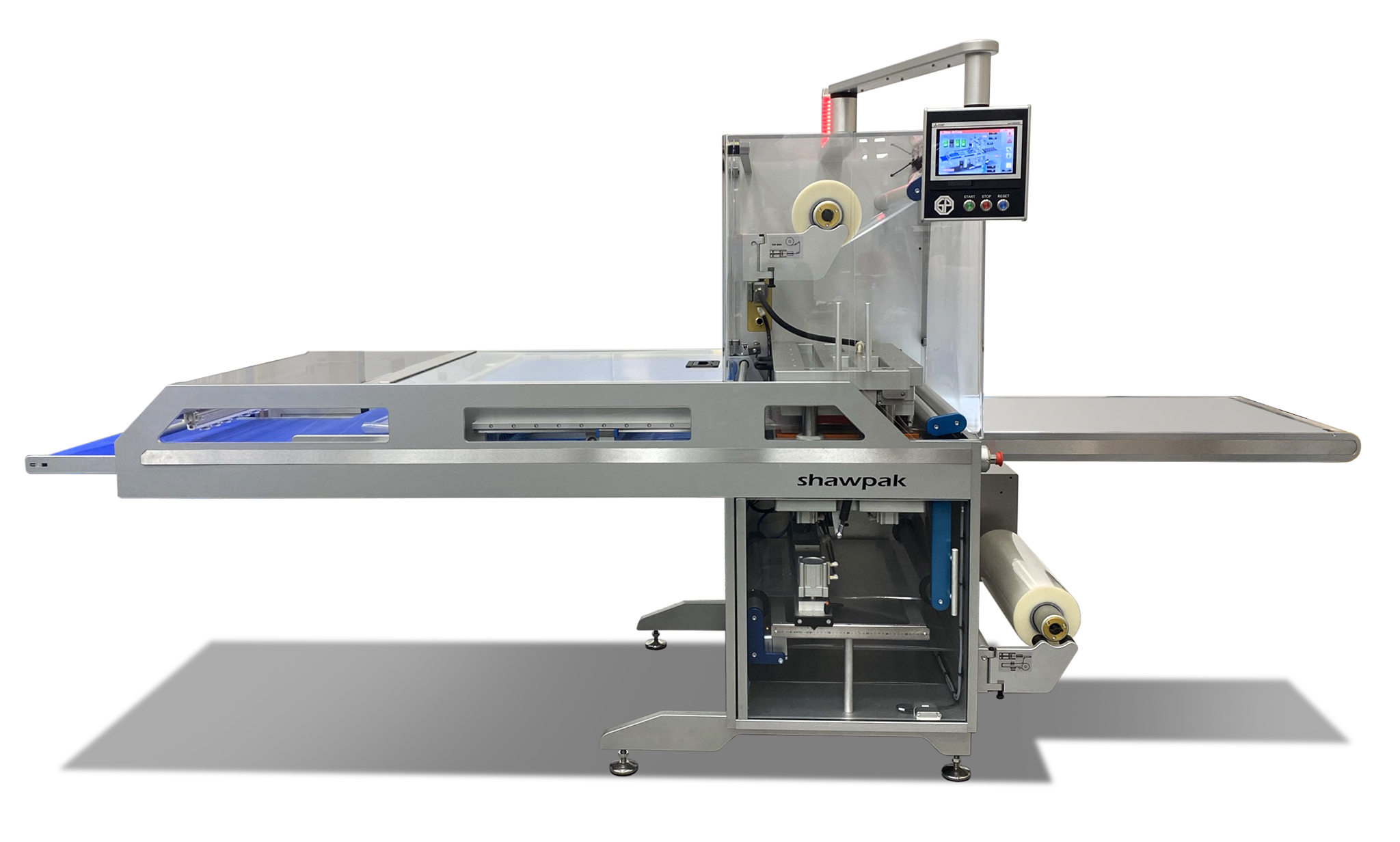

The optimal packaging for semi-finished products

Only a small part (about 5%) of the veal produced stays in the Netherlands. The remaining 95% is exported to about 50 countries, mainly Europe, China and the US. The primary buyers are wholesalers, who in turn supply the catering industry. However, there is also a growing consumer products department. Semi-finished products are packaged on the SEALPAC thermoformers, which mainly go to the (catering) wholesaler. The packaging primarily has a protective function, so that a flexible film is sufficient and sustainable. By using vacuum technology, an optimal shelf life is achieved. Christian Scholten: “If we look at the vacuum packaging based on PA/PE film, such as those that are run on the SEALPAC machines, we are actually already at the minimum packaging level. Thanks to the Rapid Air Forming concept, standard on the SEALPAC machines, the film is already as thin as possible.”

Future plans

Of course, the Corona pandemic has had an impact on Ekro, all the more so because the catering sector, and with it the wholesaler that supplies that sector with veal, has been hit. Christian Scholten: “That was especially true in the first year of the pandemic, when the catering industry in southern European countries was closed. Since then, production has picked up again and is almost back to the same level. Fortunately, we can now shift our attention to other innovation projects within Ekro.”